– 16 –

Gas leak check

Check with a leak detector or soap water whether gas

leaks or not, from the pipe connecting section or cap of

the valve.

REQUIREMENT

Use a leak detector manufactured exclusively for HFC

refrigerant (R32, R410A, R134a).

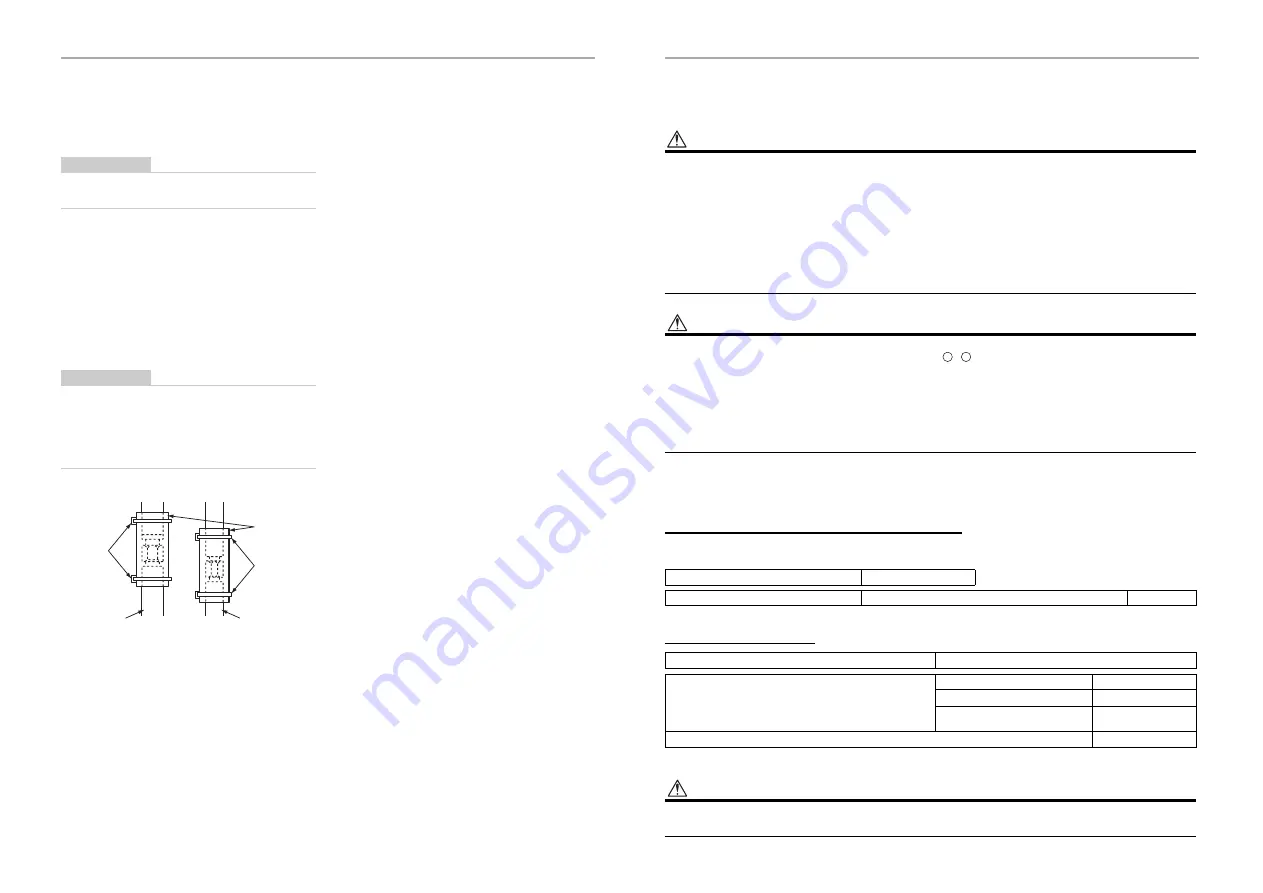

Heat insulation process

Apply heat insulation for the pipes separately at liquid

side and gas side.

• For the heat insulation to the pipes at gas side, use

the material with heat-resisting temperature 120°C

or higher.

• To use the attached heat insulation pipe, apply the

heat insulation to the pipe connecting section of the

indoor unit securely without gap.

REQUIREMENT

• Apply the heat insulation to the pipe connecting

section of the indoor unit securely up to the root

without exposure of the pipe. (The pipe exposed to the

outside causes water leak.)

• Insulate the refrigerant pipe in the indoor unit securely

up to the point shown in the following figure.

Heat

insulator

(Accessory)

Gas side

pipe

Heat

insulator

(Accessory)

Binding band

(Accessory)

Liquid side pipe

7

Electrical connection

WARNING

•

Use the specified wires for indoor and outdoor connecting wires. Securely fix them to prevent external forces

applied to the terminals from affecting the terminals.

Incomplete connection or fixation may cause a fire or other trouble.

•

Connect earth wire. (grounding work)

Incomplete earthing cause an electric shock.

Do not connect earth wires to gas pipes, water pipes, lightning conductor or telephone earth wires.

•

Appliance shall be installed in accordance with national wiring regulations.

Capacity shortage of power circuit or incomplete installation may cause an electric shock or a fire.

•

Under no circumstances, the power supply wire or the indoor and outdoor connecting wire must not be

connected in the middle (Connection using a solderless terminal etc.).

Connection trouble in the places where the wire is connected in the middle may give rise to smoking and/or a fire.

CAUTION

• For power supply specifications, follow the Installation Manual of outdoor unit.

• Do not connect 220 – 240 V power to the terminal blocks (

,

) for control wiring.

Otherwise, the system will fail.

• Do not damage or scratch the conductive core and inner insulator of power and system interconnection wires during

peeling them.

• Perform the electric wiring so that it does not come to contact with the high-temperature part of the pipe.

The coating may melt resulting in an accident.

• Be careful of fan operation when the circuit breaker is turned on. If the refrigerant leak detection sensor detects the

refrigerant leak, a fan automatically rotates even while an air conditioner stops. Be careful not to be injured by the fan.

• Do not turn on the power of the indoor unit until vacuuming of the refrigerant pipes completes.

Wiring specifications

Indoor / Outdoor connecting wires specifications

Indoor unit power supplied from outdoor unit

• The outdoor unit power supply patterns vary on models.

*Number of wire × wire size

*Including earth line

Remote controller wiring

* The remote controller wiring length differs depending on the remote controller used. For details, refer to the

Installation Manual attached to the remote controller.

CAUTION

The remote controller wire and Indoor / Outdoor connecting wires cannot be parallel to contact each other and cannot

be stored in the same conduits. If doing so, a trouble may be caused on the control system due to noise or other factor.

Indoor unit power supply

1~50 Hz 220 - 240 V

Indoor / Outdoor connecting wires*

4 × 1.5 mm² or more (H07 RN-F or 60245 IEC 66)*

Up to 70 m

Remote controller wiring, remote controller inter-unit wiring

Wire size: 2 × 0.5 to 2.0 mm²

Total wire length of remote controller wiring and remote

controller inter-unit wiring = L + L1 + L2 + … Ln

In case of wired type only

Up to 500 m

Two remote controllers

Up to 300 m

Two remote controllers with

wireless remote controller

Up to 400 m

Total wire length of remote controller inter-unit wiring = L1 + L2 + … Ln

Up to 200 m

A

B

31-EN

32-EN

Summary of Contents for RAV-HM1101FT-E

Page 31: ...EB99847901 DH91308301 ...