26-EN

25-EN

– 13 –

•

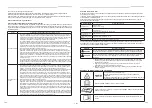

Use the tightening torque levels as listed in the

following table.

Outer dia. of connecting

pipe (mm)

Tightening torque (N

•

m)

6.4

14 to 18 (1.4 to 1.8 kgf

•

m)

9.5

34 to 42 (3.4 to 4.2 kgf

•

m)

12.7

49 to 61 (4.9 to 6.1 kgf

•

m)

15.9

63 to 77 (6.3 to 7.7 kgf

•

m)

Tightening torque of

fl

are pipe connections

Incorrect connections may cause not only a gas

leak, but also a trouble of the refrigeration cycle.

Align the centres of the connecting pipes and

tighten the

fl

are nut as far as possible with your

fi

ngers. Then tighten the nut with a spanner and

torque wrench as shown in the

fi

gure.

CAUTION

Tightening with an excessive torque may crack the nut

depending on installation conditions.

Evacuation

Perform vacuuming from the charge port of valve of

the outdoor unit by using a vacuum pump.

For details, follow to the Installation Manual attached

to the outdoor unit.

•

Do not use the refrigerant sealed in the outdoor unit

for evacuation.

REQUIREMENT

For the tools such as charge hose, use those

manufactured exclusively for R32.

Refrigerant amount to be added

For addition of the refrigerant, add refrigerant “R32”

referring to the attached Installation Manual of

outdoor unit.

Use a scale to charge the refrigerant of speci

fi

ed

amount.

REQUIREMENT

•

Charging an excessive or too little amount of

refrigerant causes a trouble of the compressor.

Charge the refrigerant of speci

fi

ed amount.

•

A personnel who charged the refrigerant should

write down the pipe length and the added refrigerant

amount in the F-GAS label of the outdoor unit. It is

necessary to

fi

x the compressor and refrigeration

cycle malfunction.

Open the valve fully

Open the valve of the outdoor unit fully. A 4 mm-

hexagonal wrench is required for opening the valve.

For details, refer to the Installation Manual attached to

the outdoor unit.

Gas leak check

Check with a leak detector or soap water whether gas

leaks or not, from the pipe connecting section or cap

of the valve.

REQUIREMENT

Use a leak detector manufactured exclusively for HFC

refrigerant (R32, R134a, R410A, etc).

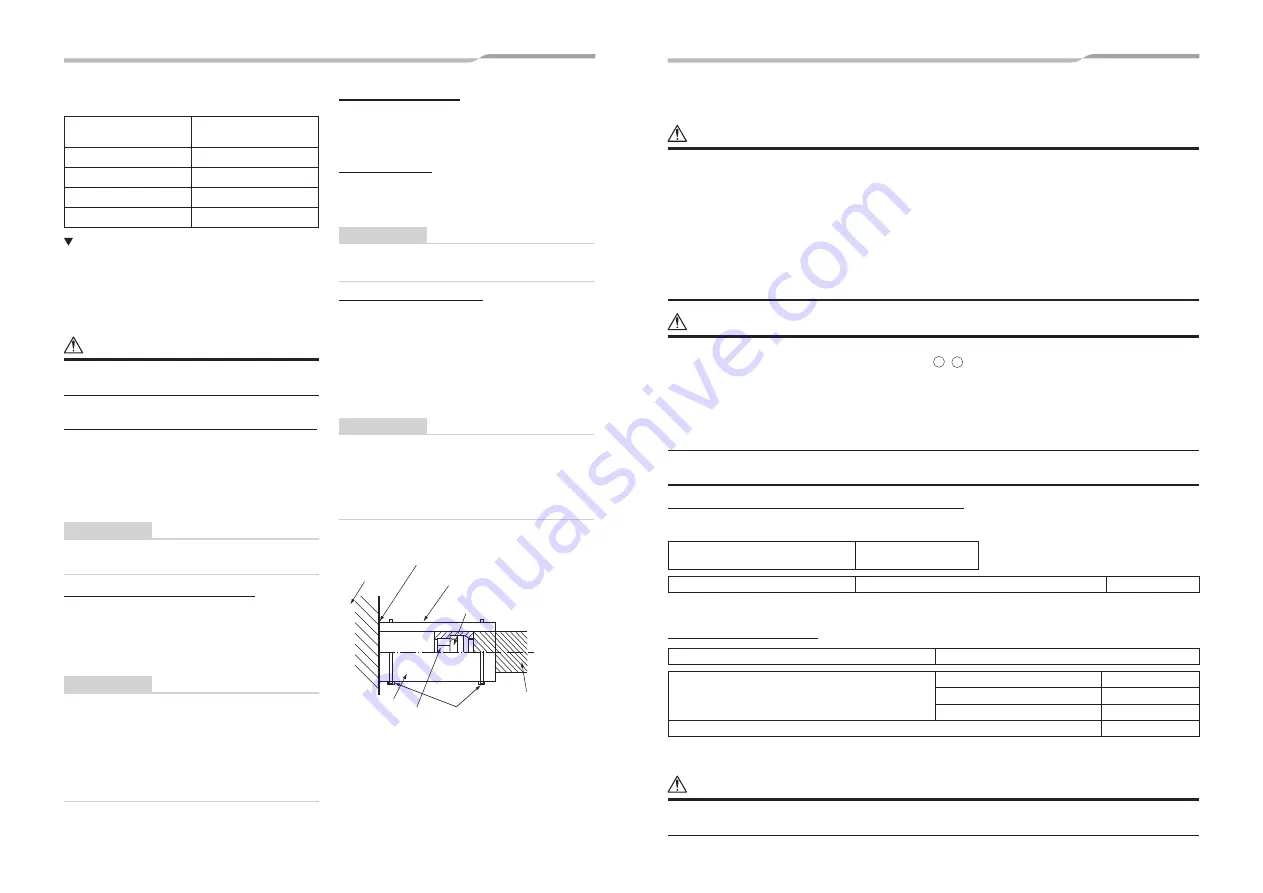

Heat insulation process

Apply heat insulation for the pipes separately at liquid

side and gas side.

•

For the heat insulation to the pipes at gas side, use

the material with heat-resisting temperature 120 °C

or higher.

•

To use the attached heat insulation pipe, apply the

heat insulation to the pipe connecting section of the

indoor unit securely without gap.

REQUIREMENT

•

Apply the heat insulation to the pipe connecting

section of the indoor unit securely up to the root

without exposure of the pipe. (The pipe exposed to

the outside causes water leak.)

•

Wrap heat insulator with its slits facing up

(ceiling side).

Wrap the pipe with the attached heat insulator

without any gap between the indoor unit.

The seam must be faced upward

(ceiling side).

Flare nut

Indoor unit

Heat insulation

pipe

(Accessory)

Banding band

(locally

procured)

Heat insulator

of the pipe

Union

7

Electrical connection

WARNING

•

Use the speci

fi

ed wires for wiring connect the terminals. Securely

fi

x them to prevent external forces applied

to the terminals from affecting the terminals.

Incomplete connection or

fi

xation may cause a

fi

re or other trouble.

•

Connect earth wire. (grounding work)

Incomplete grounding cause an electric shock.

Do not connect earth wires to gas pipes, water pipes, lightning conductor or telephone earth wires.

•

Connect earth wire. (grounding work)

Capacity shortage of power circuit or incomplete installation may cause an electric shock or a

fi

re.

•

Under no circumstances, the power supply wire or the indoor and outdoor connecting wire must not be

connected in the middle (Connection using a solderless terminal etc.)

Connection trouble in the places where the wire is connected in the middle may give rise to smoking and/or a

fi

re.

CAUTION

•

For power supply speci

fi

cations, follow the Installation Manual of outdoor unit.

•

Do not connect 220 – 240V power to the terminal blocks (

A

,

B

) for control wiring.

Otherwise, the system will fail.

•

Do not damage or scratch the conductive core and inner insulator of power and Indoor / Outdoor connecting wires

during peeling them.

•

Perform the electric wiring so that it does not come to contact with the high-temperature part of the pipe.

The coating may melt resulting in an accident.

•

Do not turn on the power of the indoor unit until vacuuming of the refrigerant pipes completes.

Wiring speci

fi

cations

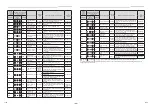

Indoor / Outdoor connecting wires speci

fi

cations

Indoor unit power supplied from outdoor unit

y

The outdoor unit power supply patterns vary on models.

Indoor unit power supply

1~50 Hz 220 - 240V

1~60 Hz 220V

Indoor / Outdoor connecting wires*

4

×

1.5 mm² or more (H07RN-F or 60245 IEC 66)*

Up to 70 m

*Number of wire

×

wire size

*Including earth line

Remote controller wiring

Remote controller wiring, remote controller inter-unit wiring

Wire size: 2 × 0.5 to 2.0 mm²

Total wire length of remote controller wiring and remote

controller inter-unit wiring = L + L1 + L2 + … Ln

In case of wired type only

Up to 500 m

2 remote controllers

Up to 300 m

In case of wireless type included

Up to 400 m

Total wire length of remote controller inter-unit wiring = L1 + L2 + … Ln

Up to 200 m

* The remote controller wiring length differs depending on the remote controller used. For details, refer to the Installation

Manual attached to the remote controller.

CAUTION

The remote controller wire and Indoor / Outdoor connecting wires cannot be parallel to contact each other and cannot

be stored in the same conduits. If doing so, a trouble may be caused on the control system due to noise or other factor.