– 2 –

CONTENTS

1. SPECIFICATIONS ............................................................................................................. 3

2. CONSTRUCTION VIEWS ................................................................................................. 5

2-1.

Outdoor Unit ....................................................................................................................................... 5

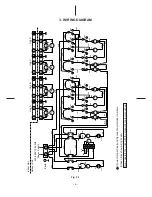

3. WIRING DIAGRAM ........................................................................................................... 6

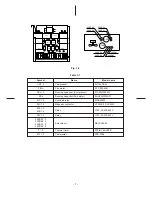

4. SPECIFICATIONS OF ELECTRICAL PARTS ................................................................... 8

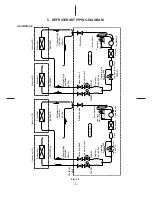

5. REFRIGERANT PIPING DIAGRAM .................................................................................. 9

5-1.

Refrigerant Piping ............................................................................................................................ 10

6. UNIT INSTALLATION ....................................................................................................... 11

6-1.

Service Space ................................................................................................................................... 11

7. OPERATIONAL MATRIX OF ELECTRICAL PARTS ....................................................... 12

8. TROUBLESHOOTING CHART FOR RAS-09EK/RAV-M240A-E .................................... 14

8-1.

What to be Prechecked First ............................................................................................................ 14

8-2.

Primary Judgement of Trouble Sources ........................................................................................... 15

8-3.

Troubleshooting Flowcharts ............................................................................................................. 19

8-4.

Test Points on the PC Board and List of Voltage Values .................................................................. 21

8-5.

How to Check the Remote Control (Including the Indoor PC Board) ............................................... 22

8-6.

PC Board Layout .............................................................................................................................. 25

9. EXPLODED VIEWS AND PARTS LIST ........................................................................... 26