CN51

CN40

SW01

Remote controller

Indoor control

P.C. board

1:1 model

connection interface

communication circuit

Terminal

resistance

1:1 model connection interface

P.C. board

MCC-1440

Indoor unit

1:1 model

connection interface

Communication units

: Total 64 units

Communication distance : 2000 m

CN050

CN041

Terminal block

(A, B)

Central controller

Indoor units in all refrigerant lines: Max. 64 units

[If mixed with SMMS (Link wiring), multi indoor units are included.]

* However group follower units of SDI, DI series are not included in number of the units.

Central control device

U1

U3

U2

U4

Central control device

U1

U3

1 2 3

U2

U4

Central control devices: Max. 10 units

Refrigerant line 1

Outdoor unit

Indoor unit

1 2 3

Refrigerant line 2

1 2 3

Refrigerant line 3

1 2 3

Refrigerant line 4

1 2 3

A B

U3 U4

Caution 3

1 2 3

A B

U3 U4

1 2 3

A B

1 2 3

A B

1 2 3

A B

1 2 3

A B

U3 U4

1:1 model connection

interface

This product

sold separately

( )

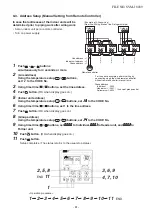

Caution 1

Remote controller

Indoor/outdoor inter-unit wire (AC230V serial)

Central control system wiring

Header unit

Header

unit

Follower

unit

Follower

unit

Follower

unit

* Wiring for No.1 and 2 only

Caution 2

Remote controller

Remote controller

Remote controller

Remote controller

wiring

Group operation (Max. 8 units)

Twin/Triple operation (Example of triple)

8-2. Setup at Local Site / Others

Model name: TCB-PCNT30TLE2

8-2-1. 1:1 Model Connection Interface (TCC-LINK adapter)

1. Function

This model is an optional P.C. board to connect the indoor unit to 1:1 model connection interface.

2. Microprocessor block diagram

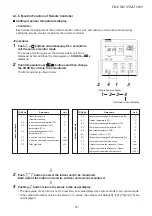

3. 1:1 model connection interface wiring connection

CAUTION

1) When controlling DI, SDI series collectively, 1:1 model connection interface (This option) is required.

2) In case of group operation, twin-triple operation, the 1:1 model connection interface is necessary to be con-

nected to the header unit.

3) Connect the central control devices to the central control system wiring.

4) When controlling DI, SDI series only, turn on only Bit 1 of SW01 of the least line of the system address No. (OFF

when shipped from the factory)

∗∗∗∗∗

In case of DI, SDI series, the address is necessary to be set up again from the wired remote

controller after automatic addressing.

FILE NO. SVM-18039

- 73 -

Summary of Contents for RAV-RM1101BTP Series

Page 18: ...RM56 type RM80 type RM110 RM140 type FILE NO SVM 18039 18 ...

Page 19: ...3 WIRING DIAGRAM FILE NO SVM 18039 19 ...

Page 34: ...5 3 Indoor Print Circuit Board MCC 1631 FILE NO SVM 18039 34 ...

Page 89: ...11 EXPLODED VIEWS AND PARTS LIST 11 1 RAV RM561BTP E RAV RM561BTP TR FILE NO SVM 18039 89 ...

Page 91: ...11 2 RAV RM801BTP E RAV RM801BTP TR FILE NO SVM 18039 91 ...

Page 94: ...11 6 RAV RM1101BTP E RAV RM1101BTP TR RAV RM1401BTP E RAV RM1401BTP TR FILE NO SVM 18039 94 ...