– 20 –

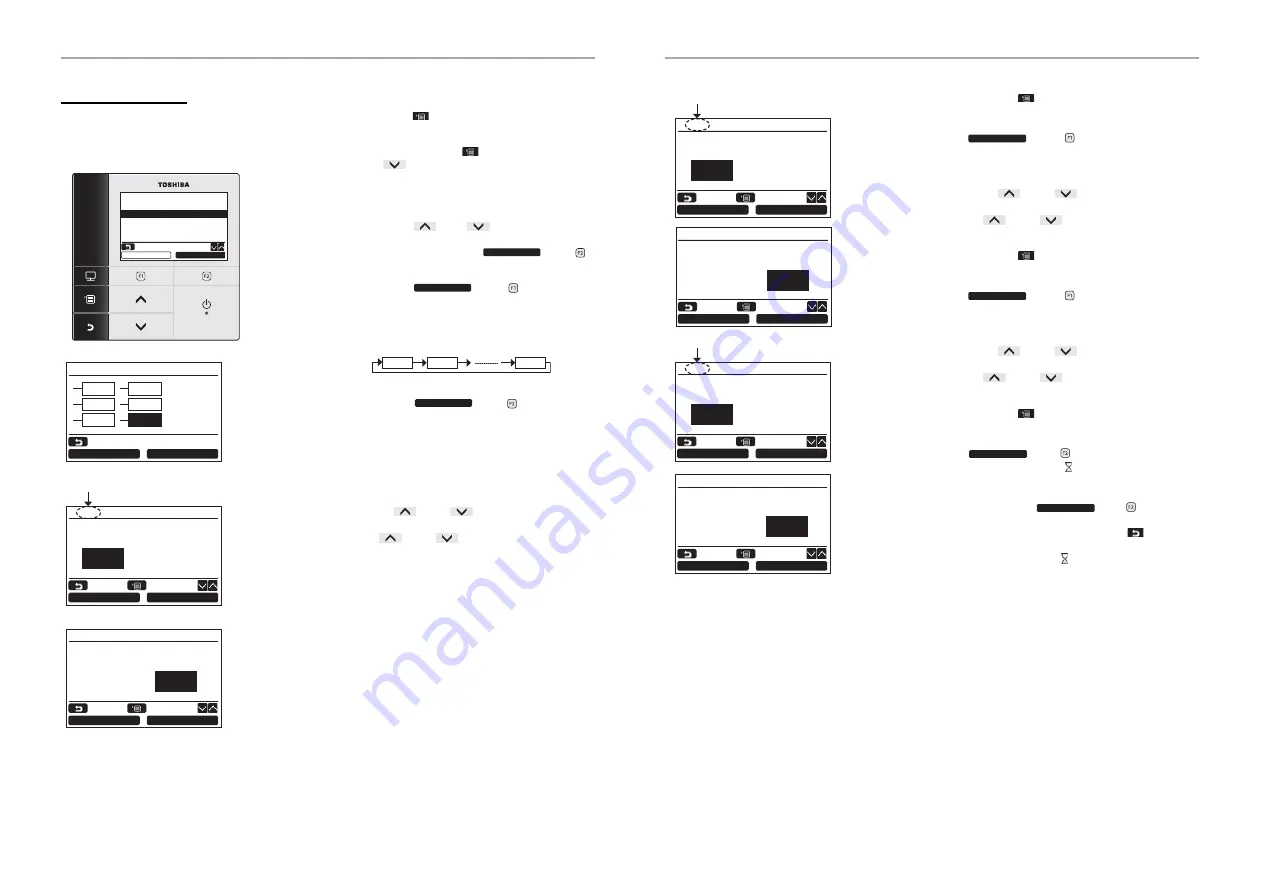

[Procedure example]

Manual address setup procedure

While the operation stops, change the setup.

(Stop the operation of the unit.)

Address is displayed here.

1

Push the [

MENU] button to display the

menu screen.

2

Push and hold the [

MENU] button and

the [

∨

] button at the same time to

display the “Field setting menu”.

Push and hold the buttons for more than 4

seconds.

3

Push the

[

∧

] / [

∨

]

button to select

"7.DN setting" on the “Field setting menu”

screen, then push the “

Set” [

F2] button.

4

Push the “

unit” [ F1] button to

select the indoor unit "3 - 3" to be changed

manually.

The selected unit changes as follows each time

the button is pushed:

5

Push the “

Set” [

F2] button.

The setting display for the selected unit

appears.

The fan and louver of the indoor unit operate.

When the group control is used, the fan and

louver of the selected indoor unit operate.

Line address change

Change “Code(DN)” from [0010] to [0012] with

the [

∧

] / [

∨

] button.

Change “Data” from [0003] to [0002] with the

[

∧

] / [

∨

] button.

6. Setting timer operation mode

7. DN setting

8. Reset power consumption data

Field setting menu(2/2)

Return

Set

DN setting

Return

1-1

1-2

2-1

2-2

3-1

3-3

Set

Unit

DN setting

Code

(DN)

Data

3-3

Return

0012

0003

Fix

<

>

DN setting

Code

(DN)

Data

3-3

Return

0002

0012

Fix

<

>

Set

Unit

1-1

1-2

3-3

Set

Address is displayed here.

Address is displayed here.

6

Push the [

MENU] button to set the other

Code(DN) and Data. After “Continue?” is

displayed on the screen, push the

“

Yes” [

F1] button.

Indoor address change

Change “Code(DN)” from [0010] to [0013] with

the [

∧

] / [

∨

] button.

Change “Data” from [0003] to [0002] with the

[

∧

] / [

∨

] button.

7

Push the [

MENU] button to set the other

Code(DN) and Data. After “Continue?” is

displayed on the screen, push the

“

Yes” [

F1] button.

Group address change

Change “Code(DN)” from [0010] to [0014] with

the [

∧

] / [

∨

] button.

Change “Data” from [0001] to [0002] with the

[

∧

] / [

∨

] button.

8

Push the [

MENU] button to set the other

Code(DN) and Data. After “Continue?” is

displayed on the screen, push the

“

No” [

F2] button to finish the

setting operation. “

Setting” appears on

the screen for a while, then the screen

returns to the “Field setting menu” screen.

Pushing the “

No” [

F2] button

displays the unit selection screen when the

group control is used. Push the [

CANCEL]

button on the unit selection screen to finish the

setting operation. “ Setting” appears on the

screen for a while, then the screen returns to the

“Field setting menu” screen.

DN setting

Code

(DN)

Data

3-3

Return

0013

0003

Fix

<

>

DN setting

Code

(DN)

Data

3-3

Return

Fix

<

>

0002

0013

DN setting

Code

(DN)

Data

3-3

Return

0014

0001

Fix

<

>

DN setting

Code

(DN)

Data

3-3

Return

Fix

<

>

0002

0014

Yes

Yes

No

No

39-EN

40-EN