Installation Manual

‒

36

‒

36-EN

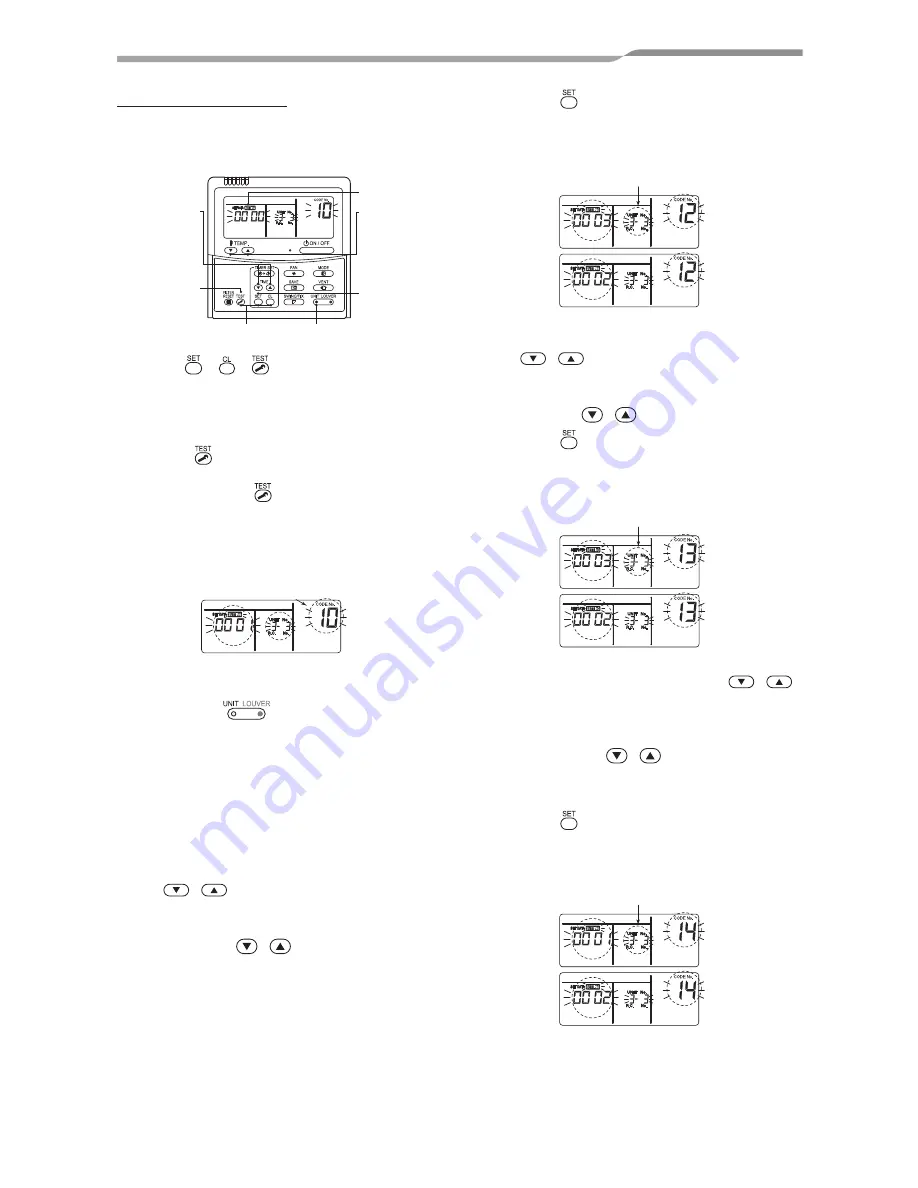

[Procedure example]

Manual address setup procedure

While the operation stops, change the setup.

(Stop the operation of the unit.)

2, 6

1

7

3

-1,

4

5

6

-1,

-1,

7

3

-3,

4

-3,

3

-2,

4

-2,

5

-2

5

-

3

1

Push

+ +

buttons simultaneously

for 4 seconds or more. After a while, the

display part

fl

ashes as shown below.

Check the displayed CODE No. is [10].

• When the CODE No. is other than [

10

],

push

button to erase the display and

repeat procedure from the

fi

rst step.

(After

pushing

button, operation of

the remote controller is not accepted for

approx. 1 minute.)

(For a group control, No. of the

fi

rstly

displayed indoor unit becomes the header

unit.)

(* Display changes according to

the model No. of indoor unit.)

2

Every time

button is pushed, the

indoor UNIT No. in the group control is

displayed in order. Select the indoor unit

of which setup is changed.

In this time, the position of the indoor unit of

which setup is changed can be con

fi

rmed

because fan of the selected indoor unit

operate.

3

1) Specify CODE No. [12] with TEMP.

/

buttons.

(CODE No. [12]: Line address)

2) Change the line address from [3] to [2]

with TIME

/

buttons.

3) Push

button.

In this time, the setup

fi

nishes when

the display changes from

fl

ashing to

lighting.

Indoor unit No. before setup change is displayed.

4

1) Specify CODE No. [13] with TEMP.

/

buttons.

(CODE No. [13]: Indoor address)

2) Change the indoor address from [3] to

[2] TIME

/

buttons.

3) Push

button.

In this time, the setup

fi

nishes when

the display changes from

fl

ashing to

lighting.

Indoor unit No. before setup change is displayed.

5

1) Specify CODE No. [14] TEMP.

/

buttons.

(CODE No. [14]: Group address)

2) Change the SET DATA from [0001] to

[0002] TIME

/

buttons.

(SET DATA [Header unit: 0001] [Follower

unit: 0002])

3) Push

button.

In this time, the setup

fi

nishes when

the display changes from

fl

ashing to

lighting.

Indoor UNIT No. before setup change is displayed.