– 62 –

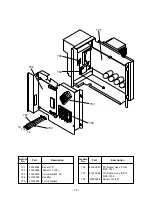

No.

Part name

Fan motor

Procedure

1) Perform works of items 1 of

and

.

2) Remove the flange nut fixing the fan motor

and propeller fan.

• The flange nut is loosened by turning it

clockwise.

(Turn it counterclockwise to tighten it.)

3) Remove the propeller fan.

4) Disconnect connector for fan motor from

the inverter.

5) Take off the fixing screws (2 pcs) while

supporting the fan motor so that it does

not fall.

* Caution when assembling fan motor

Tighten the flange nut with torque

4.9 Nm (50kgf/cm).

Remarks

Flange nut

Loosen the nut by

turning clockwise

Propeller fan

Fan motor