– 104 –

r

3 Writing of the setup contents to EEPROM

(The contents of EEPROM installed on the service P.C. board have been set up at shipment from the factory.)

1. Push

SET

,

CL

, and

TEST

buttons of the remote controller at the same time for 4 seconds or more.

1

(Corresponded with No. in Remote controller )

In group operation control, the master indoor unit No. is displayed at the first time. (If the automatic address

setup mode is interrupted in item 2. - a) - 2) in the previous page, the unit No.

ALL

is displayed.) In this time,

the item code (DN)

10

is displayed. The fan of the selected indoor unit operates and the louver starts

swinging if any.

2. Every pushing

UNIT

button, the indoor unit numbers in the group control are displayed successively.

2

Specify the indoor unit No. of which P.C. board has been replaced with a service P.C. board.

(When the unit No.

ALL

is displayed, this operation cannot be performed.)

3. Using the set temperature

/

buttons, the item code (DN) can be moved up and down one by one.

3

4. First set a type and capacity of the indoor unit.

(Setting the type and capacity writes the data at shipment from the factory in EEPROM.)

1) Set the item code (DN) to

10

. (As it is)

2) Using the timer time

/

buttons, set up a type.

4

(For example, 4-way air discharge cassette type is 0001) Refer to the attached table.

3) Push

SET

button. (OK when the display goes on.)

5

4) Using the set temperature

/

buttons, set

11

to the item code (DN).

5) Using the timer time

/

buttons, set the capacity.

(For example, 0012 for class 80) Refer to the attached table.

6) Push

SET

button. (OK when the display goes on.)

7) Push

TEST

button to return the status to usual stop status.

6

(Approx. 1 minute is required to start handling of the remote controller.)

5. Next write the contents which have been set up at the local site such as the address setup in EEPROM.

Repeat the above procedure 1. and 2.

6. Using the set temperature

/

buttons, set

01

to the item code (DN).

(Setup of lighting time of filter sign)

7. The contents of the displayed setup data in this time should be agreed with the contents in the previous

memorandum in

r

1.

1) If data disagree, change the displayed setup data to that in the previous memorandum by the timer time

/

buttons, and then push

SET

button. (OK when the display goes on.)

2) There is nothing to do when data agrees.

8. Using the set temperature

/

buttons, change the item code (DN).

As same as the above, check the contents of the setup data and then change them to data contents in the

previous memorandum.

9. Then repeat the procedure 7. and 8.

10. After completion of setup, push

TEST

button to return

the status to the usual stop status.

6

(Approx. 1 minute is required to start handling of

the remote controller.)

*

01

to

9F

are provided in the item code (DN).

On the way of operation, DN No. may come out.

When data has been changed by mistake and

SET

, button has been pushed, the data can be

returned to the data before change by pushing

CL

button if the item code (DN) was not yet

changed.

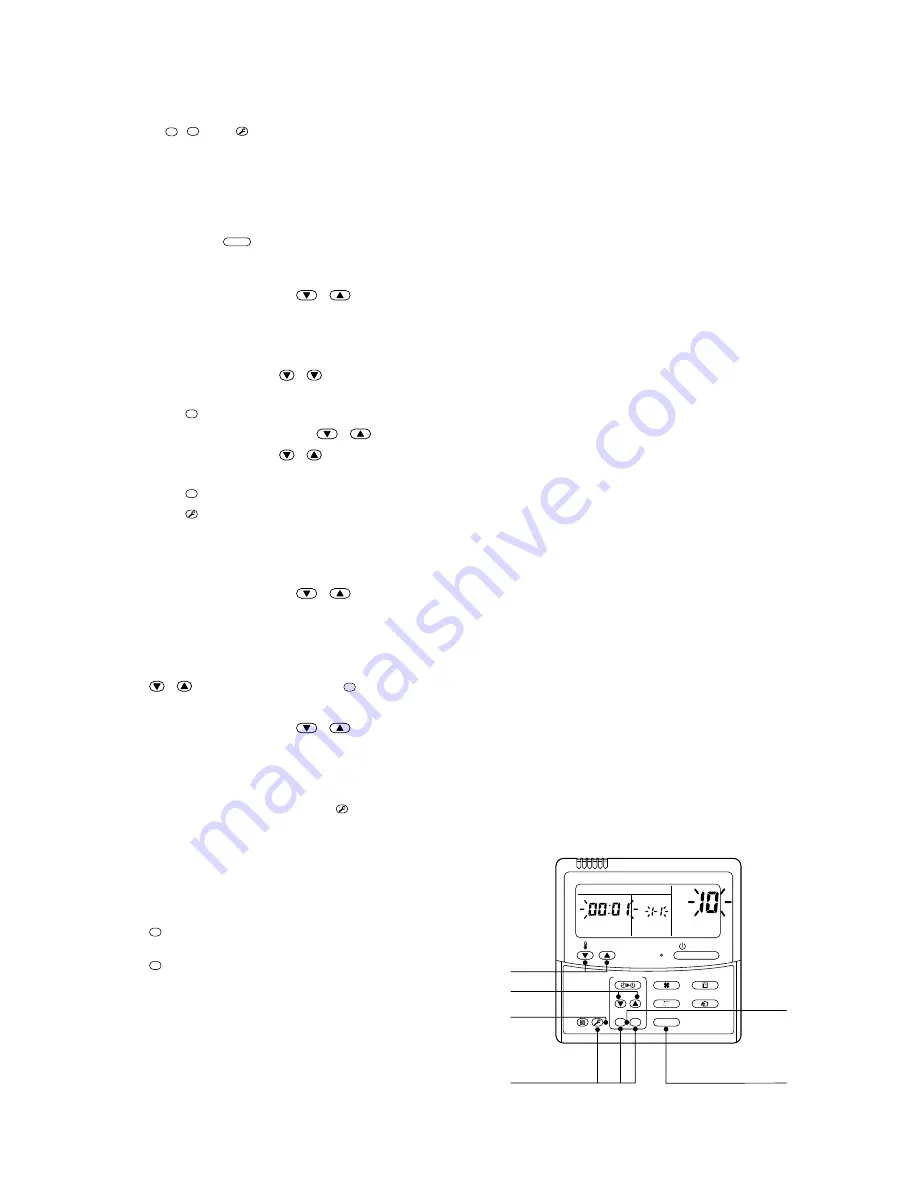

<REMOTE CONTROLLER>

1

4

6

3

2

5

ON / OFF

FAN

TEMP.

SWING/FIX

TIME

MODE

VENT

UNIT

SET

CL

FILTER

RESET TEST

TIMER SET

UNIT No.

DATA

SET

R.C.

No.

Toshiba SDI / DI tuotteiden jälleenmyyjä pääkaupunkiseudulla on Jäähdytinpalvelu RefGroup Oy

www.ilmalämpöpumput.com