– 66 –

No.

9

10

11

Item

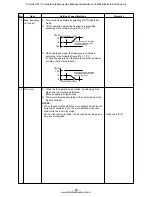

Drain pump control

After-heat

elimination

Louver control

(For 4-way air

discharge cassette

type only)

Outline of specifications

1) In cooling operation (including Dry operation), the

drain pump is usually operated.

2) If the float switch operates while drain pump

operates, the compressor stops, the drain pump

continues the operation, and a check code is

output.

3) If the float switch operates while drain pump stops,

the compressor stops and the drain pump oper-

ates. If the float switch keeps operating for approx.

4 minutes, a check code is output.

When heating operation stops, the indoor fan oper-

ates with LOW mode for approx. 30 seconds.

1) Louver position setup

• When the louver position is changed, the

position moves necessarily to downward dis-

charge position once to return to the set posi-

tion.

• The louver position can be set up in the follow-

ing operation range.

In cooling/dry operation

In heating/fan operation

• In group twin/triple operation, the louver posi-

tions can be set up collectively or individually.

2) Swing setup

• The swinging position can be moved in the

following operation range.

All modes

• In group twin/triple operation, the swinging

positions can be set up collectively or individu-

ally.

3) When the unit stops or when a warning is output,

the louver automatically moves downward.

4) While the heating operation is ready, the louver

automatically moves upward.

Remarks

Check code [P10]

W arning :

A check code is displayed

on the remote controller,

and the indoor unit stops.

(Excluding [F08] and

[L31])

Toshiba SDI / DI tuotteiden jälleenmyyjä pääkaupunkiseudulla on Jäähdytinpalvelu RefGroup Oy

www.ilmalämpöpumput.com