– 59 –

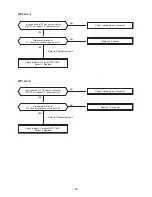

[1] Setting data read out from EEPROM

The setting data modified on the site, other than factory-set value, stored in the EEPROM shall be read

out.

Step 1

Push

SET

,

CL

and

TEST

button on the remote controller simultaneously for more than 4 seconds.

∗

When the group operation control is performed, the unit No. displayed for the first time is the header unit No.

At this time, the CODE No. (DN) shows “

10

10

10

10

10

”. Also, the fan of the indoor unit selected starts its operation

and the swing operation also starts if it has the louvers.

Step 2

Every time when the

UNIT LOUVER

button is pushed, the indoor unit No. under the group control is displayed in

order. Specify the indoor unit No. to be replaced.

1. Change the CODE No. (DN) to

10

10

10

10

10

→

01

01

01

01

01

by pushing

/

buttons for the temperature

setting. (this is the setting for the filter sign lighting time.)

At this time, be sure to write down the setting data displayed.

2. Change the CODE No. (DN) by pushing

/

buttons for the temperature setting.

Similarly, be sure to write down the setting data displayed.

3. Repeat the step 2-2 to set the other settings in the same way and write down the setting data as shown

in the table 1 (example).

∗

The CODE No. (DN) are ranged from “

01

01

01

01

01

” to “

FF

FF

FF

FF

FF

”. The CODE No. (DN) may skip.

Step 3

After writing down all setting data, push

TEST

button to return to the normal stop status.

(It takes approx. 1 min until the remote controller operation is available again.)

CODE No. required at least

1. The CODE No. for the Indoor unit type and Indoor unit capacity are

required to set the rotation number setting of the fan.

2. If the system/indoor/group addresses are different from those before

replacement, the auto-address setting mode starts and the manual

resetting may be required again.

(when the multiple units group operation including twin system.)

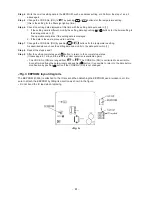

[2] P.C. Board for indoor unit servicing replacement procedures

Step 1

Replace the P.C. board to the P.C. board for indoor unit servicing.

At this time, perform the same setting of the jumper wire (J01) setting (cut), switch SW501, (short-circuit)

connector CN34 as the setting of the P.C. board before replacement.

Step 2

According to the system configuration, turn on the indoor unit following to the either methods shown below.

a) Single operation (Indoor unit is used as standalone.)

Turn on the indoor unit.

1. After completion of the auto-address setting mode (required time: approx. 5 min.), proceed to [3].

(System address = 1, Indoor unit address = 1, Group address = 0 (standalone) are automatically set.)

2. Push

SET

,

CL

and

TEST

buttons simultaneously for more than 4 seconds to interrupt the auto-address

setting mode, and proceed to [3]. (The unit No. “

” is displayed.)

b) Group operation (including twin system)

Turn on the indoor unit(s) with its P.C. board replaced to the P.C. board for indoor unit servicing, accord-

ing to either methods 1 or 2 shown below.

1. Turn on only the indoor unit with its P.C. board replaced. (Be sure to confirm the remote controller is

surely connected. If not, the operation [3] cannot be performed.)

Perform either methods 1 or 2 described in item a) above.

2. Turn on the multiple indoor units including the indoor unit with its P.C. board replaced.

• Twin 1 system only

• All group connections

After completion of the auto-address setting mode (required time: approx. 5 min.), proceed to

[3]

.

∗

The header unit of the group may be changed by performing the auto-address setting.

Also, the system address/Indoor unit address of the indoor unit with its P.C. board replaced may be

assigned to the addresses (not used) other than those of the indoor units without its P.C. board replaced.

It is recommended to keep the information in advance, which cooling system the indoor unit belongs to or

whether the indoor unit works as the header unit or the follower unit in the group control operation.

DN

10

11

12

13

14

5d

Contents

Type

Indoor unit capacity

System address

Indoor unit address

Group address

External static pressure.

Summary of Contents for RAV-SM1106BT-E

Page 18: ... 18 ...

Page 19: ... 19 3 WIRING DIAGRAM ...

Page 34: ... 34 5 3 Indoor Print Circuit Board MCC 1631 ...

Page 89: ... 89 11 EXPLODED VIEWS AND PARTS LIST 11 1 RAV SM406BT E RAV SM456BT E RAV SM566BT E ...

Page 91: ... 91 11 2 RAV SM806BT E ...

Page 93: ... 93 11 3 RAV SM406BT TR RAV SM456BT TR RAV SM566BT TR ...

Page 95: ... 95 11 4 RAV SM806BT TR ...

Page 98: ... 98 11 6 RAV SM1106BT E RAV SM1406BT E RAV SM1606BT E ...

Page 100: ... 100 11 7 RAV SM1106BT TR RAV SM1406BT TR RAV SM1606BT TR ...