– 12 –

Concealed Duct High Static Pressure

Installation Manual

EN

5

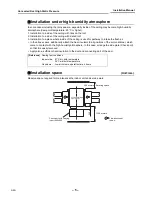

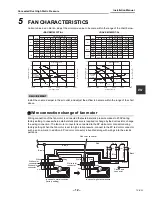

FAN CHARACTERISTICS

Current value as a criterion, adjust the air volume value to become within the range of the chart below.

REQUIREMENT

Install the volume damper in the air outlet, and adjust the airflow to become within the range of the chart

above.

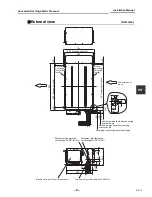

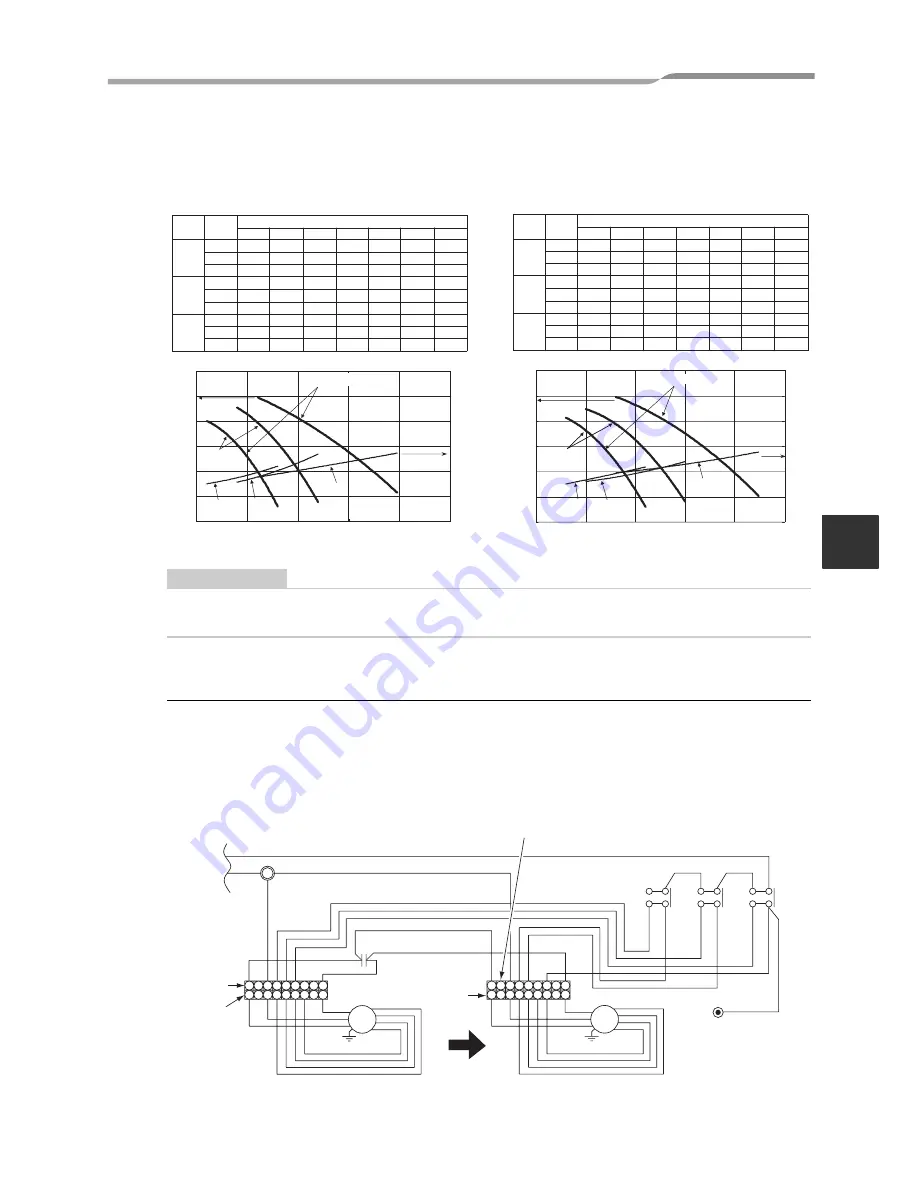

Wire connection change of fan motor

Wiring connection of the fan motor is connected that external static pressure makes to 200P during

factory setting. In cases where external static pressure is required to change by the duct resistor, change

the wiring connection. The fan motor connector is connected to the 9P white color connector during

factory setting. When the fan motor is set to high static pressure, connect to the 9P red color connector

such as arrow mark. In addition, 9P red color connector is bundled along with wirings into the electric

parts box.

Hi

CMM

Med

CMM

Low

l/s

CMM

Fan-tap

m

3

/h

l/s

m

3

/h

m

3

/h

l/s

(unit)

Hi

CMM

Med

CMM

Low

l/s

CMM

Fan-tap

m

3

/h

l/s

m

3

/h

m

3

/h

l/s

(unit)

0

50

100

150

200

250

300

1,500

2,000

2,500

3,000

3,500

4,000

Static pressure (Pa)

0

1

2

3

4

5

6

Motor current (A)

Hi

Med.

Low

Hi

Med.

Low

High static pressure

Air volume(m3/h)

0

50

100

150

200

250

300

1,500

2,000

2,500

3,000

3,500

4,000

Static pressure (Pa)

0

1

2

3

4

5

6

Motor current (A)

Hi

Med.

Low

Low

Med.

Hi

Air volume(m3/h)

Normal

Condition

(ex factory)

Normal

Condition

(ex factory)

High static pressure

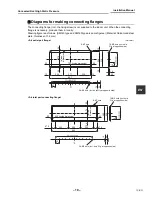

30

40

50

100

200

225

250

3,480 3,300 2,500 2,330 2,100

966

916

694

647

583

55.0

41.6

38.8

2,700 2,670 2,500 2,100 1,900

750

742

694

583

527

45.0

41.6

35.0

31.6

2,300 2,270 2,250 2,100 1,600

638

631

625

583

513

38.3

37.8

35.0

30.8

Static Pressure (Pa)

35.0

58.0

44.5

37.5

Static Pressure (Pa)

30

40

50

100

200

225

250

3,740 3,500 2,800 2,600 2,300

1,038

972

777

722

638

58.3

46.6

43.3

3,000 2,970 2,790 2,260 2,000

833

825

775

627

555

50.0

46.5

37.6

33.3

2,600

2,550 2,380 1,850

722

717

708

66

513

43.3

43.0

39.6

30.8

2,580

62.3

49.5

42.5

38.3

<RAV-SM1403DT-A>

<RAV-SM1603DT-A>

FM

RC

9

7

9

6

5

4

3

6

5

4

3

1

1

9

FM

6

5

7

4

3

1

9

5

7

3

1

4

4

43F3

43F2

6

3

5

2

4

6

3

5

43F1

4

6

3

5

White color

connector

White color

connector

White

Gray

Gray

Red

Ye

llo

w

Blue

In case of high static pressure

In case of normal condition

(factory setting)

Red color connector

Brown

Brown

White

Gray

White

Ye

llo

w

Bl

u

e

Ora

nge

Bla

ck

Re

d

Gray

Ye

llow

Blue

Red

Red

Black

Black

O

range

Closed end

connector

Ye

llo

w

Bl

u

e

Ora

nge

Bla

ck

Re

d

White

White color

connector

12-EN