EH99884201

WARNINGS ON REFRIGERANT LEAKAGE

Check of Concentration Limit

The room in which the air conditioner is to be installed requires a design that in the event of

refrigerant gas leaking out, its concentration will not exceed a set limit.

The refrigerant R410A which is used in the air conditioner is safe, without the toxicity or combustibility of ammonia,

and is not restricted by laws to be imposed which protect the ozone layer. However, since it contains more than air, it

poses the risk of suffocation if its concentration should rise excessively. Suffocation from leakage of R410A is almost

non-existent. With the recent increase in the number of high concentration buildings, however, the installation of multi

air conditioner systems is on the increase because of the need for effective use of floor space, individual control,

energy conservation by curtailing heat and carrying power etc.

Most importantly, the multi air conditioner system is able to replenish a large amount of refrigerant compared with

conventional individual air conditioners. If a single unit of the multi conditioner system is to be installed in a small

room, select a suitable model and installation procedure so that if the refrigerant accidentally leaks out, its

concentration does not reach the limit (and in the event of an emergency, measures can be made before injury can

occur).

In a room where the concentration may exceed the limit, create an opening with adjacent rooms, or install mechanical

ventilation combined with a gas leak detection device.

The concentration is as given below.

The concentration limit of R410A which is used in multi air conditioners is 0.3 kg/m

3

.

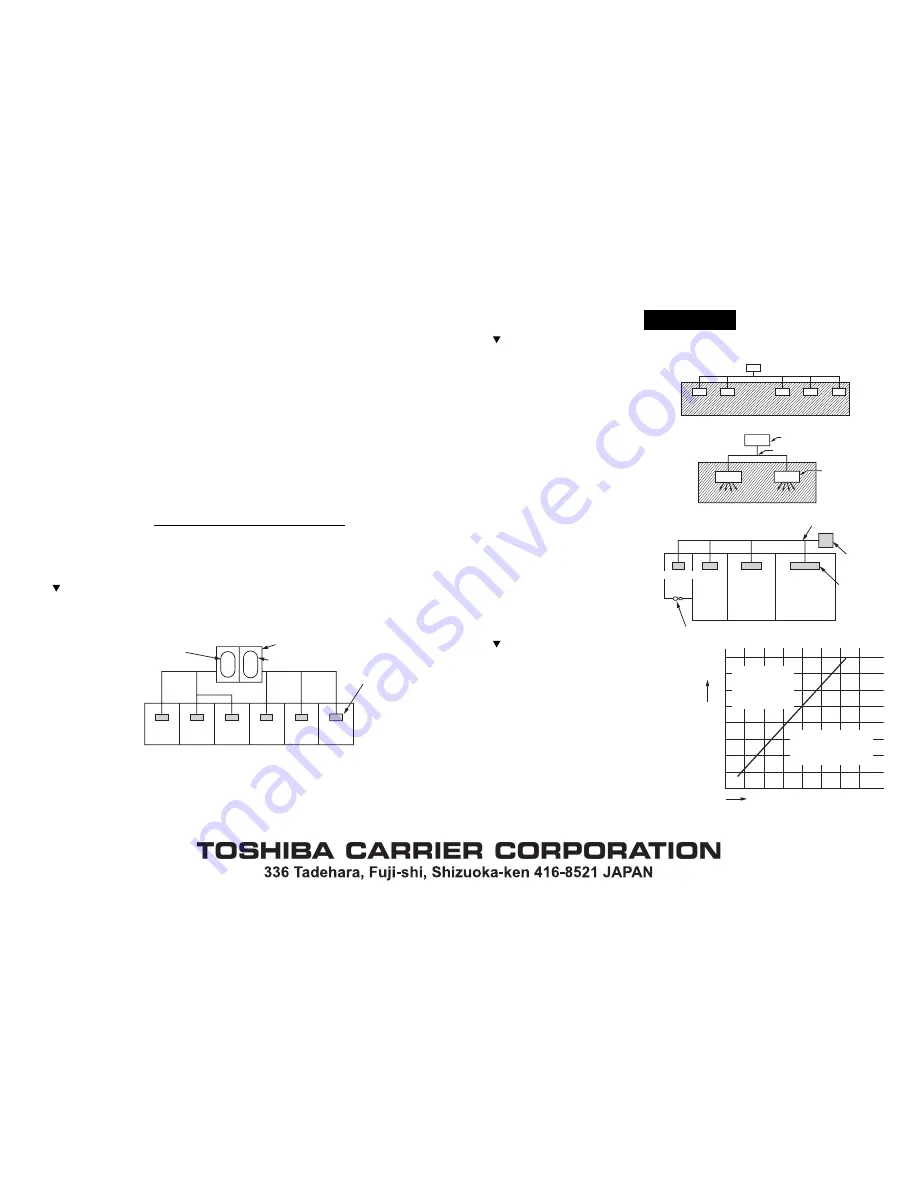

NOTE 1

If there are 2 or more refrigerating systems in a single refrigerating device, the amounts of refrigerant should be as

charged in each independent device.

For the amount of charge in this example:

The possible amount of leaked refrigerant gas in rooms A, B and C is 10 kg.

The possible amount of leaked refrigerant gas in rooms D, E and F is 15 kg.

Total amount of refrigerant (kg)

Min. volume of the indoor unit installed room (m

3

)

≤

Concentration limit (kg/m

3

)

e.g., charged amount (10 kg)

Outdoor unit

e.g., charged amount (15 kg)

Indoor unit

Room A

Room B Room C Room D Room E Room F

NOTE 2

The standards for minimum room volume are as follows.

(1) No partition (shaded portion)

(2) When there is an effective opening with the

adjacent room for ventilation of leaking refrigerant gas

(opening without a door, or an opening 0.15% or

larger than the respective floor spaces at the top or

bottom of the door).

(3) If an indoor unit is installed in each

partitioned room and the refrigerant

piping is interconnected, the smallest

room of course becomes the object. But

when a mechanical ventilation is

installed interlocked with a gas leakage

detector in the smallest room where the

density limit is exceeded, the volume of

the next smallest room becomes the

object.

NOTE 3

The minimum indoor floor area compared with the amount

of refrigerant is roughly as follows:

(When the ceiling is 2.7m high)

Important

Outdoor unit

Refrigerant piping

Indoor unit

Refrigerant piping

Outdoor unit

Indoor unit

Mechanical ventilation device - Gas leak detector

Very small room

Small

room

Medium

room

Large room

0

5

10

10

20

30

15

20

25

30

35

40

m

2

Min

. indo

or flo

o

r area

Total amount of refrigerant

kg

Range below the

density limit of

0.3 kg/m

3

(countermeasures

not needed)

Range above the density

limit of 0.3 kg/m

3

(countermeasures

needed)

Summary of Contents for RAV-SM1603AT-A

Page 15: ... 14 MEMO EN 27 EN 28 ...