� 24 �

47-EN

48-EN

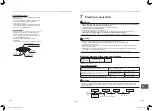

Error codes and parts to be checked

Wired

remote

controller

display

Wireless remote controller

Sensor block display of

receiving unit

Main defective parts

Judging

device

Parts to be checked / error description

Air

conditioner

status

Indication

Operation Timer

Ready

GR GR OR

Flashing

E01

No header remote

controller

Remote

controller

Incorrect remote controller setting --- The header

remote controller has not been set (including two

remote controllers).

*

Remote controller

communication error

No signal can be received from the indoor unit.

E02

Remote controller

transmission error

Remote

controller

System interconnection wires, indoor P.C. board,

remote controller --- No signal can be sent to the

indoor unit.

*

E03

Indoor unit-remote

controller regular

communication error

Indoor

Remote controller, network adapter, indoor

P.C. board --- No data is received from the remote

controller or network adapter.

Auto-reset

E04

Indoor unit-outdoor unit

serial communication

error

Indoor

System interconnection wires, indoor P.C. board,

outdoor P.C. board --- Serial communication error

between indoor unit and outdoor unit

Auto-reset

IPDU-CDB

communication error

E08

Duplicated indoor

addresses

Indoor

Indoor address setting error --- The same address

as the self-address was detected.

Auto-reset

E09

Duplicated header

remote controllers

Remote

controller

Remote controller address setting error --- Two

remote controllers are set as header in the

double remote controller control.

*

(* The header indoor unit stops raising alarm and

follower indoor units continue to operate.)

E10

CPU-CPU

communication error

Indoor

Indoor P.C. board --- Communication error between

main MCU and motor microcomputer MCU

Auto-reset

E18

Header unit

follower unit regular

communication error

Indoor

Indoor P.C. board --- Regular communication is

not possible between header and follower indoor

units or between twin header (main) and follower

(sub) units.

Auto-reset

E31

IPDU communication

error

Outdoor

Communication error between IPDU and CDB

Entire stop

F01

ALT

Indoor unit heat

exchanger sensor

(TCJ) error

Indoor

Heat exchanger sensor (TCJ), indoor P.C. board ---

Open-circuit or short-circuit of the heat exchanger

sensor (TCJ) was detected.

Auto-reset

F02

ALT

Indoor unit heat

exchanger sensor (TC)

error

Indoor

Heat exchanger sensor (TC), indoor P.C. board ---

Open-circuit or short-circuit of the heat exchanger

sensor (TC) was detected.

Auto-reset

F04

ALT

Outdoor unit discharge

temp. sensor (TD) error Outdoor

Outdoor temp. sensor (TD), outdoor P.C. board ---

Open-circuit or short-circuit of the discharge temp.

sensor was detected.

Entire stop

F06

ALT

Outdoor unit temp.

sensor (TE/TS) error

Outdoor

Outdoor temp. sensors (TE/TS), outdoor P.C. board

--- Open-circuit or short-circuit of the heat

exchanger temp. sensor was detected.

Entire stop

F07

ALT

TL sensor error

Outdoor

TL sensor may be displaced, disconnected or

short-circuited.

Entire stop

F08

ALT

Outdoor unit outside air

temp. sensor error

Outdoor

Outdoor temp. sensor (TO), outdoor P.C. board ---

Open-circuit or short-circuit of the outdoor air temp.

sensor was detected.

Operation

continued

F10

ALT

Indoor unit room temp.

sensor (TA) error

Indoor

Room temp. sensor (TA), indoor P.C. board ---

Open-circuit or short-circuit of the room temp.

sensor (TA) was detected.

Auto-reset

Wired

remote

controller

display

Wireless remote controller

Sensor block display of

receiving unit

Main defective parts

Judging

device

Parts to be checked / error description

Air

conditioner

status

Indication

Operation Timer

Ready

GR GR OR

Flashing

F12

ALT

TS sensor error

Outdoor

TS sensor may be displaced, disconnected or

short-circuited.

Entire stop

F13

ALT

Heat sink sensor error

Outdoor

Abnormal temperature was detected by the temp.

sensor of the IGBT heat sink.

Entire stop

F15

ALT

Temp. sensor

connection error

Outdoor

Temp. sensor (TE/TS) may be connected

incorrectly.

Entire stop

F29

SIM

Indoor unit, other

P.C. board error

Indoor

Indoor P.C. board --- EEPROM error

Auto-reset

F31

SIM

Outdoor unit P.C. board Outdoor

Outdoor P.C. board ---- In the case of EEPROM

error.

Entire stop

H01

Outdoor unit

compressor

breakdown

Outdoor

Current detect circuit, power voltage --- Minimum

frequency was reached in the current releasing

control or short-circuit current (Idc) after direct

excitation was detected

Entire stop

H02

Outdoor unit

compressor lock

Outdoor

Compressor circuit --- Compressor lock was

detected.

Entire stop

H03

Outdoor unit current

detect circuit error

Outdoor

Current detect circuit, outdoor unit P.C. board ---

Abnormal current was detected in AC-CT or a

phase loss was detected.

Entire stop

H04

Case thermostat

operation (1)

Outdoor

Malfunction of the case thermostat

Entire stop

H06

Outdoor unit

low-pressure system

error

Outdoor

Current, high-pressure switch circuit, outdoor P.C.

board --- Pressure sensor error was detected or

low-pressure protective operation was activated.

Entire stop

L03

SIM

Duplicated header

indoor units

Indoor

Indoor address setting error --- There are two or

more header units in the group.

Entire stop

L07

SIM

Group line in individual

indoor unit

Indoor

Indoor address setting error --- There is at least

one group-connected indoor unit among individual

indoor units.

Entire stop

L08

SIM

Indoor group address

not set

Indoor

Indoor address setting error --- Indoor address

group has not been set.

Entire stop

L09

SIM

Indoor unit capacity

not set

Indoor

Indoor unit capacity has not been set.

Entire stop

L10

SIM

Outdoor unit P.C. board Outdoor

In the case of outdoor P.C. board jumper wire

(for service) setting error

Entire stop

L20

SIM

LAN communication

error

Network

adapter

central

control

Address setting, central control remote controller,

network adapter --- Duplication of address in

central control communication

Auto-reset

L29

SIM

Other outdoor unit

error

Outdoor

Other outdoor unit error

Entire stop

1) Communication error between IPDU MCU and

CDB MCU

Entire stop

2) Abnormal temperature was detected by the heat

sink temp. sensor in IGBT.

L30

SIM

Abnormal external

input into indoor unit

(interlock)

Indoor

External devices, outdoor unit P.C. board ---

Abnormal stop due to incorrect external input into

CN80

Entire stop

L31

SIM

Phase sequence

error, etc.

Outdoor

Power supply phase sequence, outdoor unit P.C.

board --- Abnormal phase sequence of the 3-phase

power supply

Operation

continued

(thermost

at OFF)

EN

1115652713-1_EN,FR,ES.indd 25

25/3/2565 15:47:12