– 43 –

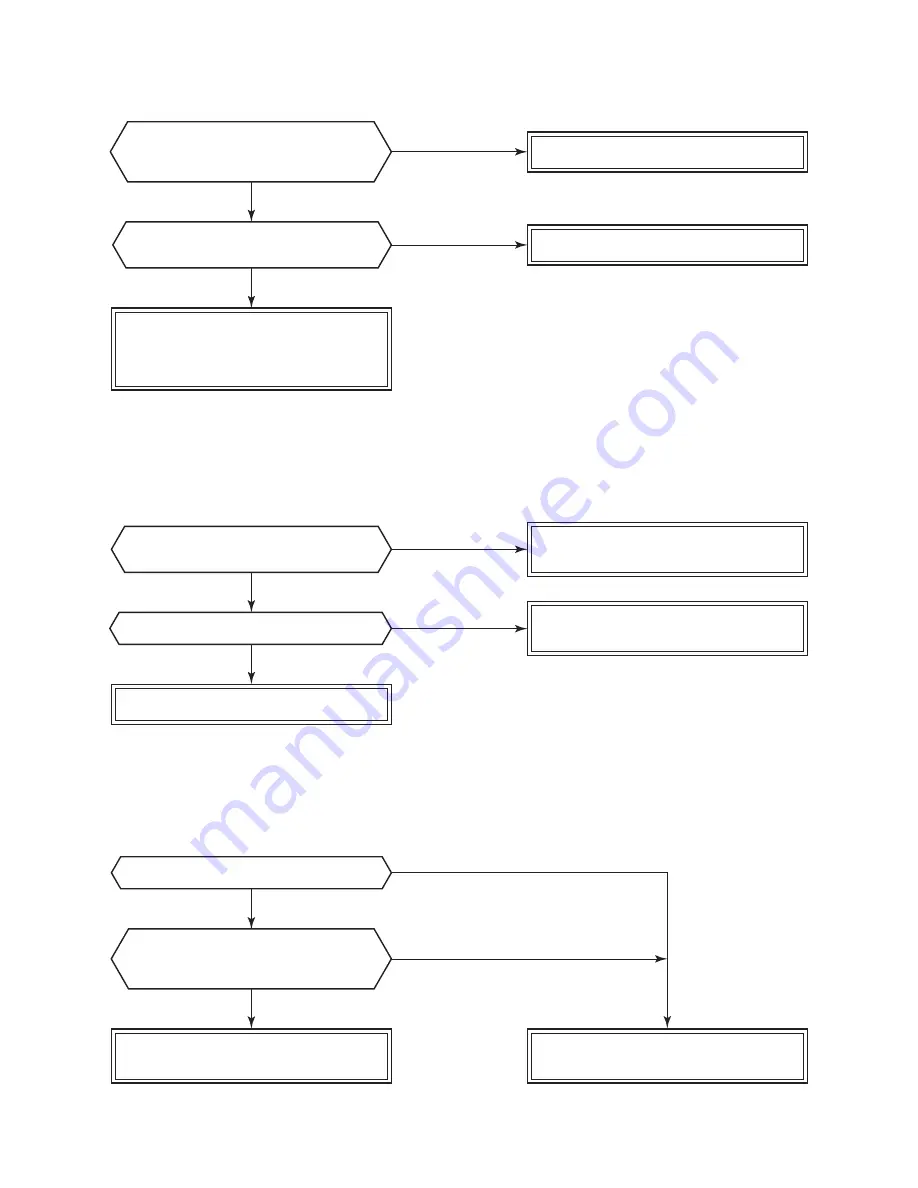

[L20 error]

Is group operation carried out?

Do outside devices normally work?

Check cause of operation.

Check corresponding

indoor unit/outdoor unit.

Are outside devices of

connector CN80 connected?

Is not the multiple same central

control system addresses connected?

Is there check code

on sub remote controller in main

and sub remote controllers?

Are wiring connections

to communication lines

U3 and U4 normal?

Check central controller

(including network adapter) and

indoor P.C. board (MCC-1403).

Defect

→

Replace

Correct wiring connection.

Correct central control system address.

Check indoor P.C. board (MCC-1403).

Defect

→

Replace

Check outside devices.

Defect

→

Replace

Check indoor P.C. board (MCC-1403).

Defect

→

Replace

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

[L30 error]

[P30 error] (Central controller)