– 93 –

Concealed Duct High Static Pressure

Installation Manual

Concealed Duct High Static Pressure

Installation Manual

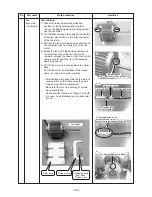

Tightening connection

CAUTION

Do not apply excessive torque. Otherwise, the

nut may crack depending on the conditions.

(Unit: N•m)

u

Tightening torque of flare pipe connections

Pressure of R410A is higher than that of R22.

(Approx. 1.6 times)

Therefore, using a torque wrench, tighten the flare pipe

connecting sections which connect the indoor and

outdoor units of the specified tightening torque.

Incorrect connections may cause not only a gas leak,

but also a trouble of the refrigeration cycle.

Align the centres of the connecting pipes and tighten

the flare nut as far as possible with your fingers.

Then tighten the nut with a spanner and torque wrench

as shown in the figure.

Externally

threaded side

Internally

threaded side

Half union

Flare nut

Use a wrench to secure.

Use a torque wrench to tighten.

REQUIREMENT

Tightening with an excessive torque may crack the nut

depending on installation conditions.

Tighten the nut within the specified tightening torque.

n

Gas side refrigerant pipe

connection

• Turn up the pipe heat insulator to the unit side.

• Wrap the pipe with wet cloth.

Turn up pipe heat insulator

Remove the all brazed part.

Wet cloth

• Remove the cup on the gas side piping by using a

brazing machine.

CAUTION

Do not burn the pipe heat insulator.

Remove the cap.

Connection pipe

Locally procured

Ø28.6 mm

Attached joint part

• Braze the attached joint part to the gas side piping and

braze the connection piping to the joint part.

Braze all around

Brazing

Brazing

• Turn back the pipe heat insulator and tie up with a

banding band.

Tie up with a banding band.

Piping with outdoor unit

• For details of installation, refer to the Installation Manual

of the outdoor unit.

n

Evacuation

Using a vacuum pump, perform vacuuming from the

charge port of valve of the outdoor unit.

For details, follow to the Installation Manual attached to the

outdoor unit.

• Never use the refrigerant sealed in the outdoor unit for

evacuation.

REQUIREMENT

For the tools such as charge hose, etc., use those

manufactured exclusively for R410A.

Outer dia. of copper pipe

12.7 mm (dia.)

Tightening torque

50 to 62 (5.0 to 6.2 kgf•m)

Refrigerant amount to be added

For addition of the refrigerant, add refrigerant “R410A”

referring to the attached Installation Manual of outdoor unit.

Be sure to use a scale to charge the refrigerant of specified

amount.

REQUIREMENT

• Charging an excessive or too little amount of refrigerant

causes a trouble of the compressor.

Be sure to charge the refrigerant of specified amount.

• A personnel who charged the refrigerant should write

down the pipe length and the added refrigerant amount in

the nameplate attached to the service panel of the

outdoor unit.

It is necessary to fix the compressor and refrigeration

cycle malfunction.

Open the valve fully

Open the valve of the outdoor unit fully.

A 4mm-hexagonal wrench is required for opening the valve.

For details, refer to the Installation Manual attached to the

outdoor unit.

Gas leak check

Check with a leak detector or soap water whether gas leaks

or not, from the pipe connecting section or cap of the valve.

REQUIREMENT

Use a leak detector manufactured exclusively for HFC

refrigerant (R410A, R134a, etc.).

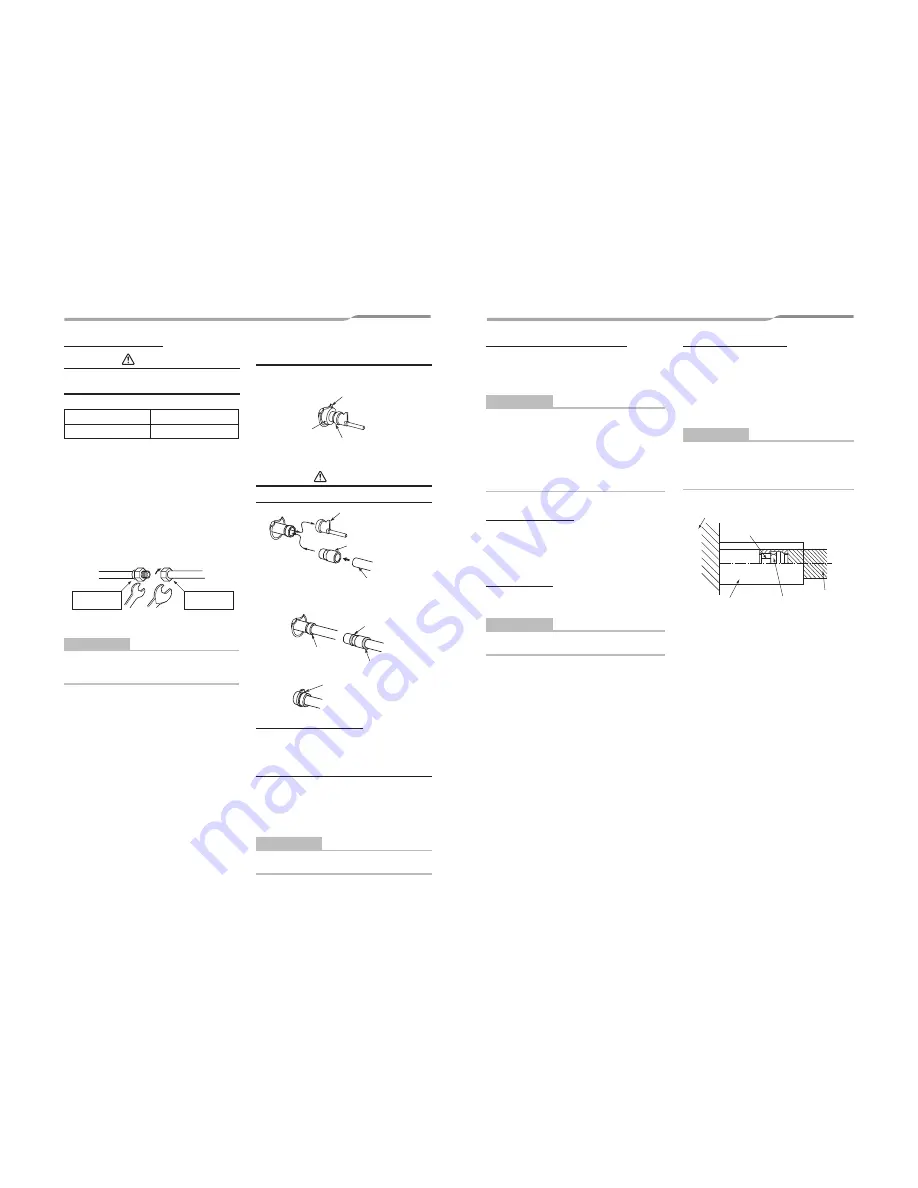

Heat insulation process

Apply heat insulation for the pipes separately at liquid

side and gas side.

For the heat insulation to the pipes at gas side, be sure to

use the material with heat-resisting temperature 120°C or

higher.

Using the attached heat insulation material, apply the

heat insulation to the pipe connecting section of the

indoor unit securely without gap.

REQUIREMENT

• Apply the heat insulation to the pipe connecting section

of the indoor unit securely up to the root without

exposure of the pipe.

(The pipe exposed to the outside causes water leak.)

• Wrap heat insulator with its slits facing up (ceiling side).

Indoor unit

Union

Heat insulation

(Accessory)

Flare nut

Heat insulator

of the pipe

– 23 –

– 24 –