10

EN

Digital Inverter

5

REFRIGERANT PIPING

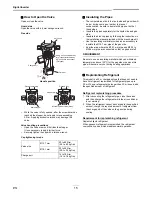

Knockout of Pipe Cover

Knockout procedure

•

The indoor/outdoor connecting pipes can be connected

in 4 directions.

Take off the knockout part of the pipe cover through

which pipes or wires will pass through the base plate.

•

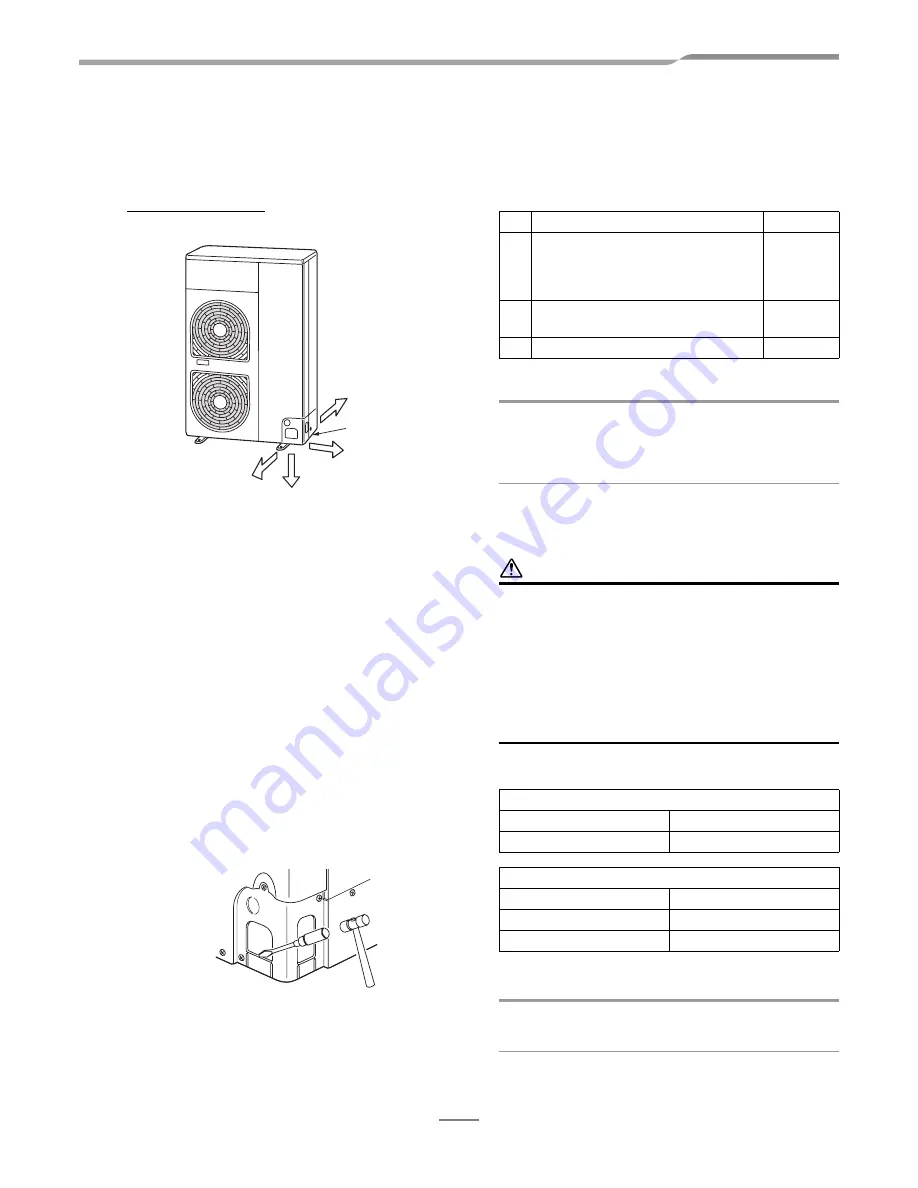

Detach the pipe cover and tap on the knockout section a

few times with the shank of a screwdriver. A knockout

hole can easily be punched.

•

As shown in the figure below, it is easier to punch out the

knockout hole when the pipe cover is left in place rather

than when the cover is removed from the unit.

In knocking out the hole, the knockout section can easily

be removed by hand once the bottom of the three

locations where the section is joined along the guide lines

is broken using a screwdriver.

•

After punching out the knockout hole, remove burrs from

the hole, and install the protective bush and guard

material around the passage hole provided as

accessories in order to protect the wires and pipes. Also

be sure to attach the pipe covers after connecting the

pipes. The pipe covers can be easily attached by cutting

off the slits at the lower part of the covers.

*

Be sure to wear heavy work gloves while working.

Optional Installation Parts

(Locally procured)

REQUIREMENT

Follow the instructions in the installation manual provided

with the branch pipe kit and the instructions in the installation

manual of the indoor unit to connect the refrigerant pipe

between the branch pipe and indoor unit.

Refrigerant Piping Connection

CAUTION

TAKE NOTE OF THESE 4 IMPORTANT POINTS BELOW

FOR PIPING WORK

1. Keep dust and moisture away from inside the connecting

pipes.

2. Tightly connect the connection between pipes and the

unit.

3. Evacuate the air in the connecting pipes using a

VACUUM PUMP.

4. Check for gas leaks at connection points.

Piping connection

REQUIREMENT

On the gas side, be sure to use the Ø19.1 mm pipe provided

with the outdoor unit.

Rear direction

Pipe cover

Side direction

Down direction

Front direction

Parts name

Q’ty

A

Refrigerant piping

Liquid side: Ø12.7 mm

Gas side: Ø19.1 mm (Approx. 800 mm)

Ø28.6 mm

One each

B

Pipe insulating material

(polyethylene foam, 10 mm thick)

1

C

Putty, PVC tape

One each

Liquid side

Outer diameter

Thickness

Ø12.7 mm

0.8 mm

Gas side

Outer diameter

Thickness

Ø19.1 mm

1.2 mm

Ø28.6 mm

1.0 mm (half hard)