28-EN

27-EN

– 14 –

EN

EN

EN

EN

7

Refrigerant piping

Refrigerant piping

1.

Use the following items for the refrigerant

piping.

Material : Seamless phosphorous deoxidized

copper pipe.

Wall thickness : 0.8 mm or more Ø12.7 mm

(C1220T-0)

1.0 mm or more for Ø28.6 mm

(C1220T-1/2H).

Do not use any copper pipes with a wall

thickness less than these thicknesses.

2. Flare nut and

fl

are works are also different from

those of the conventional refrigerant.

Take out the

fl

are nut attached to the main unit of

the air conditioner, and use it.

REQUIREMENT

When the refrigerant pipe is long, provide support

brackets at intervals of 2.5 to 3 m to clamp the

refrigerant pipe. Otherwise, abnormal sound may

be generated.

CAUTION

Important 4 points for piping work

1. Remove dust and moisture from the inside of the

connecting pipes.

2. Tight connection (between pipes and unit)

3. Evacuate the air in the connecting pipes using

VACUUM PUMP.

4. Check the gas leakage. (Connected points)

Pipe size

Pipe size

Gas side

28.6 mm

Liquid side

12.7 mm

Liquid side refrigerant pipe

connection

Permissible piping length and height

difference

They vary according to the outdoor unit.

For details, refer to the Installation Manual attached to

the outdoor unit.

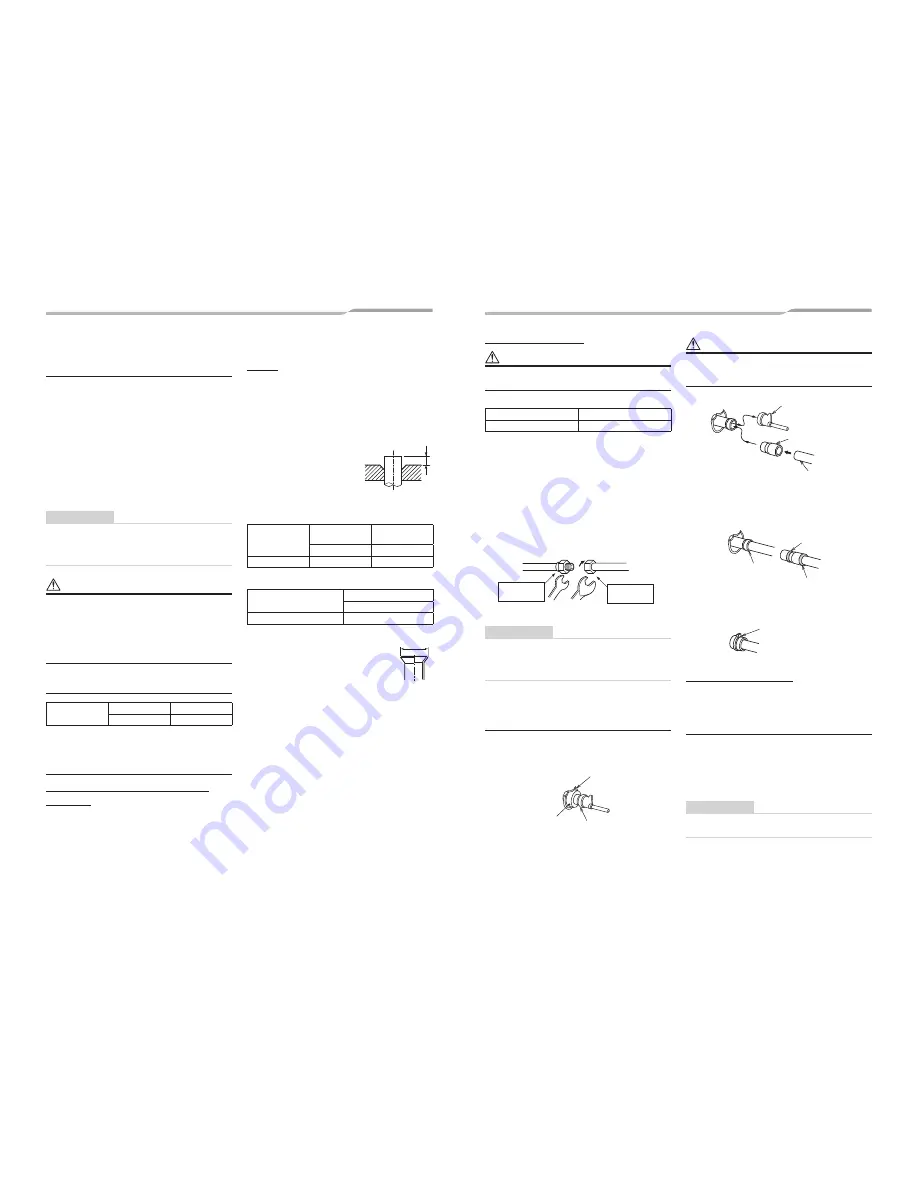

Flaring

y

Cut the pipe with a pipe cutter.

Remove burrs completely.

Remaining burrs may cause gas leakage.

y

Insert a

fl

are nut into the pipe, and

fl

are the pipe.

As the

fl

aring sizes of R410A differ from those of

refrigerant R22, the

fl

are tools newly manufactured

for R410A are recommended.

However, the conventional

tools can be used by adjusting

projection margin of the copper

pipe.

B

q

Projection margin in

fl

aring: B (Unit: mm)

Rigid (Clutch type)

Outer dia. of

copper pipe

R410A tool used

Conventional

tool used

R410A

R410A

12.7

0 to 0.5

1.5 to 2.0

q

Flaring diameter size: A (Unit: mm)

Outer dia. of copper pipe

A

+0

-0.02” (–0.4)

R410A

12.7

16.6

* In case of

fl

aring for R410A with the

conventional

fl

are tool, pull it out approx.

0.5 mm more than that for R22 to adjust

to the speci

fi

ed

fl

are size.

The copper pipe gauge is useful for

adjusting projection margin size.

A

Tightening connection

CAUTION

Do not apply excessive torque. Otherwise, the

nut may crack depending on the conditions.

(Unit: N•m)

Outer dia. of copper pipe

Tightening torque

12.7 mm (dia.)

50 to 62 (5.0 to 6.2 kgf•m)

q

Tightening torque of

fl

are pipe connections

Pressure of R410A is higher than that of R22.

(Approx. 1.6 times) Therefore, using a torque wrench,

tighten the

fl

are pipe connecting sections which

connect the indoor and outdoor units of the speci

fi

ed

tightening torque.

Incorrect connections may cause not only a gas leak,

but also a trouble of the refrigeration cycle.

Align the centres of the connecting pipes and tighten

the

fl

are nut as far as possible with your

fi

ngers. Then

tighten the nut with a spanner and torque wrench as

shown in the

fi

gure.

Half union

Flare nut

Externally

threaded side

Internally

threaded side

Use a wrench to secure.

Use a torque wrench to tighten.

REQUIREMENT

Tightening with an excessive torque may crack the

nut depending on installation conditions.

Tighten the nut within the speci

fi

ed tightening

torque.

Gas side refrigerant pipe

connection

y

Turn up the pipe heat insulator to the unit side.

y

Wrap the pipe with wet cloth.

Turn up pipe heat

insulator

Remove the all

brazed part.

Wet cloth

y

Remove the cup on the gas side piping by using a

brazing machine.

CAUTION

y

Do not burn the pipe heat insulator.

y

Be careful for the

fl

ame, due to the brazing

process on the ceiling.

Remove the cap

Connection pipe

Locally procured

Ø28.6 mm

Attached joint part

y

Braze the attached joint part to the gas side piping

and braze the connection piping to the joint part.

Brazing

Braze all around

Brazing

y

Turn back the pipe heat insulator and tie up with a

banding band.

Tie up with a banding

band.

Piping with outdoor unit

For details of installation, refer to the Installation

Manual of the outdoor unit.

Evacuation

Using a vacuum pump, perform vacuuming from the

charge port of valve of the outdoor unit.

For details, follow to the Installation Manual attached

to the outdoor unit.

y

Never use the refrigerant sealed in the outdoor unit

for evacuation.

REQUIREMENT

For the tools such as charge hose, etc., use those

manufactured exclusively for R410A.