– 117 –

No. Part name

Procedure

Remarks

i

Compressor

and

compressor

lead

(continued)

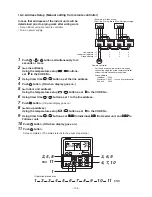

2. Compressor attachment

1) Detachment of the reverse order of removal.

NOTE

• Also ensure to replace the compressor lead after

replacing the compressor. (Compressor lead

replacement code: 43160658)

At this time please ensure to wind the compressor lead 4

times around the ferrite core.

(Ensure to position the ferrite core the same as when

before removed.)

• Install the sound insulation board (inner and outer)

through the space between the compressor and the

piping, and between the pipes and separate plate as

shown on the right.

• Fix in place with commercially available heat-resistant

code clamps through the pipe cover so that the TD

sensor lead does not come in direct contact with the

discharge pipe.

3. Vacuum

1) Connect the vacuum pump to the charge port of the

liquid and gas pipe valves and the check joint on the

high pressure side, and then operate the vacuum

pump.

2) Vacuum until the vacuum low pressure gauge reaches

1 (mmHg).

NOTE

Fully open the electronic control valve before the vacuum

process. If closed the vacuum pipe between the liquid pipe

valve and electronic control valve of the outdoor unit may

not be able to be drawn through.

Method for forcibly fully opening the electronic control

valve

• Turn on the power supply breaker.

• Ensure that D805 of the LED indication of the outdoor

unit is lit up. If D805 is not lit up (off or flashing) then

push and hold down SW01 and SW02 at the same time

for at least 5 seconds and check that D805 lights up.

• Push and hold SW01 down for at least 5 seconds or to

confirm that D804 is slowly flashing (once/second).

• Push SW01 several times until the the LED indications

(D800 to D804) become the following.

• Push SW02 and D805 will start rapidly flashing.

• Push and hold SW02 down for at least 5 seconds and

D804 will start slowly flashing. Once D805 lights up the

PMV will start to open.

After 30 seconds turn off the power breaker.

4. Refrigerant encapsulation

1) Add the amount of refrigerant determined by the pipe

length using the charge port of the valve.

D800

: Go ON, : Go OFF, : cflash (5 times/sec.)

D801

D802

D803

D804

LED display board

LED indication

Wind the compressor lead

4 times around the ferrite core

Ferrite core

Compressor lead

The soundproof

The soundproof

board (outer ring)

board (outer ring)

should match this

should match this

position

position

The soundproof

board (outer ring)

should match this

position

Excess compressor leads and

compressor case thermo leads

should be positioned between

the inside and outside of the

soundproofing board.

Pass the soundproof board (inner ring)

through the compressor, the discharge

pipe, and the suction pipe and overlap

it in this position.

Do not leave any gap between the

soundproof board (top) and the

soundproof board (outer ring).

Soundproof

Soundproof

board (top)

board (top)

Soundproof

Soundproof

board (outer ring

board (outer ring

Soundproof

board (top)

Soundproof

board (outer ring

Inverter cover

SW01

SW02