– 50 –

6-6-6. Handling of Existing Pipe

When using the existing pipe, carefully check it for

the following:

• Wall thickness (within the specified range)

• Scratches and dents

• Water, oil, dirt, or dust in the pipe

• Flare looseness and leakage from welds

• Deterioration of copper pipe and heat insulator

• Before recovering the refrigerant in the existing

system, perform a cooling operation for at least 30

minutes.

Cautions for using existing pipe

• Do not reuse a flare nut to prevent gas leaks.

Replace it with the supplied flare nut and then

process it to a flare.

• Blow nitrogen gas or use an appropriate means to

keep the inside of the pipe clean.

If discolored oil or much residue is discharged,

wash the pipe.

• Check welds, if any, on the pipe for gas leaks.

• There may be a problem with the pressure

resistance of the branching pipes of the existing

piping.

Replace them with branch pipes (sold separately).

When the pipe corresponds to any of the following,

do not use it. Install a new pipe instead.

• The pipe has been opened (disconnected from

indoor unit or outdoor unit) for a long period.

• The pipe has been connected to an outdoor unit

that does not use refrigerant R22, R410A or

R407C.

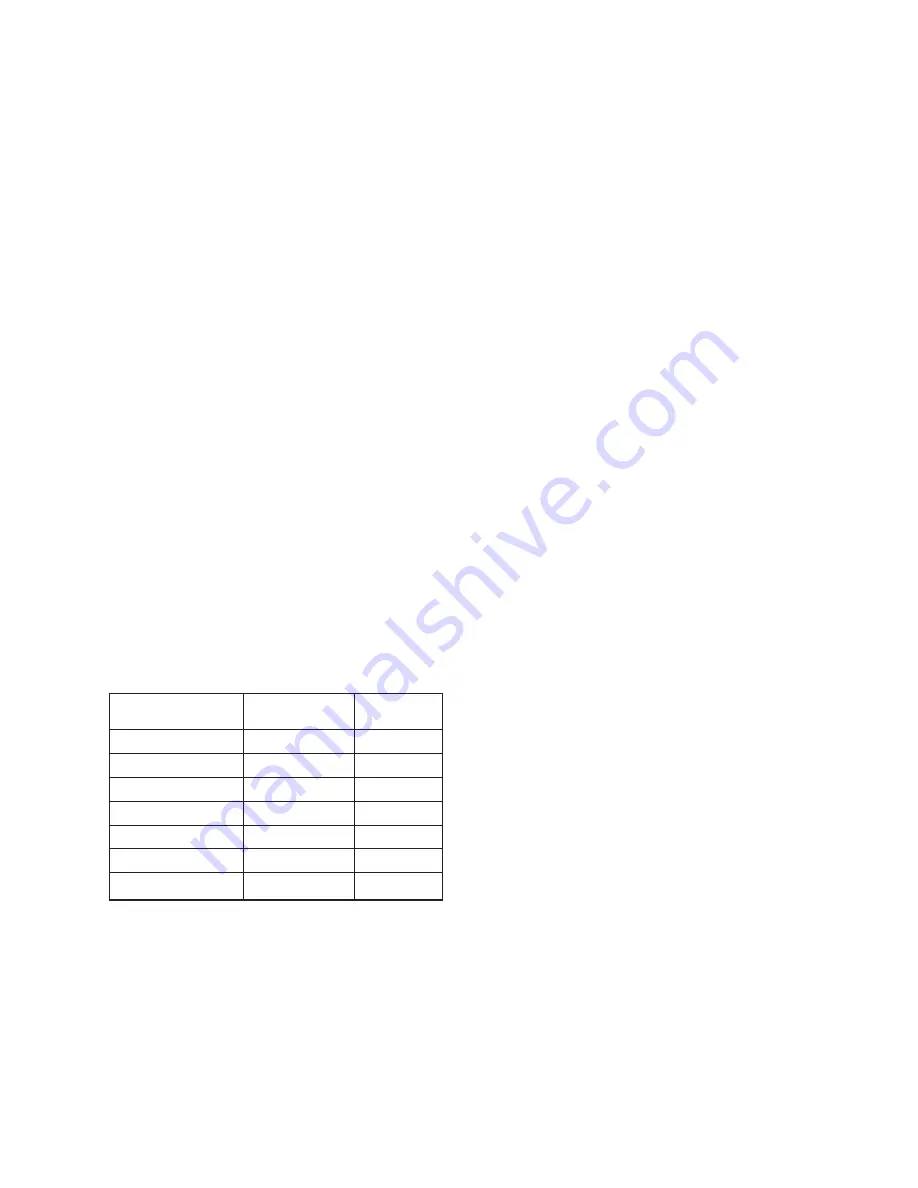

• The existing pipe must have a wall thickness equal

to or larger than the following thicknesses.

Reference outside

diameter (mm)

6.4

9.5

12.7

15.9

19.1

22.2

28.6

Wall thickness

(mm)

0.8

0.8

0.8

1.0

1.2

1.0

1.0

Material

—

—

—

—

—

Half hard

Half hard

• Do not use any pipe with a wall thickness less than

these thicknesses due to insufficient pressure

capacity.

6-6-7. Recovering Refrigerant

Use the refrigerant recovery equipment to recover the

refrigerant.