– 92 –

No. Part name

Procedure

Remarks

l

Fan motor

1. Detachment

1) Remove the turbo fan, electric parts cover, wiring cover

and wiring fixing plate.

(Refer to

h

-1,

d

-1,

i

-1-2,

i

-1-3.)

2) Remove the fan motor connector (CN210, White, 7P)

connected to the control P.C. board, and then take off

the lead wires from the clamp.

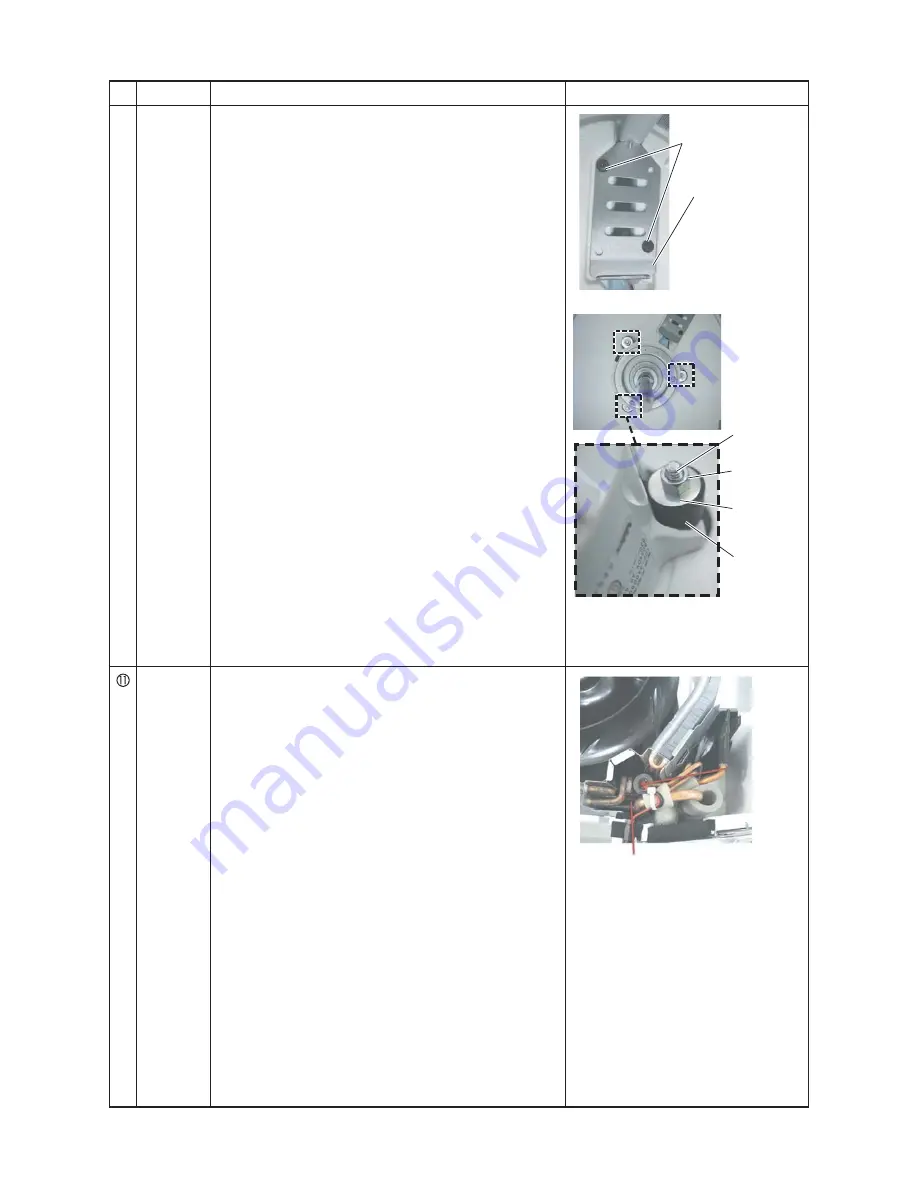

3) Remove the shoulder screws (Black, 2pcs.) of the

motor lead wiring cover, and separate the lead wires

and the lead wire cover.

4) Remove the hexagon nuts (M6) which fix the motor,

and the washers. (3 pcs. Each).

* When taking off them, hold them with a hand so that

motor will not fall down.

5) Remove the motor with rubber cushion from the bolt.

2. Attachment

1) Pass rubber cushion of the motor in the bolt, put the

washer and the hexagon nut in this order, and then

tighten to fix them.

(Tightening toque: 4.9 ± 0.5N•m)

2) Pass the lead wire through the motor lead wire fixing

plate removed in 1-3), and then fix it with shoulder

screw.

3) Perform wiring of the motor lead wires as original,

connect the connector to the control P.C. board, and

then attach the wiring fixing plate and the wiring cover.

4) Following to works in

h

-2 and

d

-2, attach the turbo

fan and the electric parts covers.

S

ho

u

lder

s

crew

s

(Bl

a

ck)

Motor le

a

d wire cover

Bolt

Hex

a

gon n

u

t

W

as

her

R

ubb

er

c

us

hion

TC

TCJ

Sensor

1. Detachment

1) Remove the drain pan. (Refer to

i

-1.)

2) Pull out the sensor to be exchanged from the sensor

holder.

3) Remove the connector connected to the control P.C.

board, and take off wires from the clamp. (Refer to

g

.)

2. Attachment

1) Insert the sensor to be exchanged into the specified

sensor. (Refer to the right figure.)

2) Perform wiring of the sensor as original.

TCJ

s

en

s

or

TCJ

s

en

s

or

(Red)

(Red)

TCJ

s

en

s

or

(Red)

TC

s

en

s

or (Bl

a

ck)