– 10 –

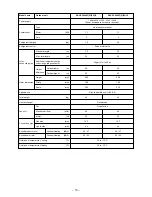

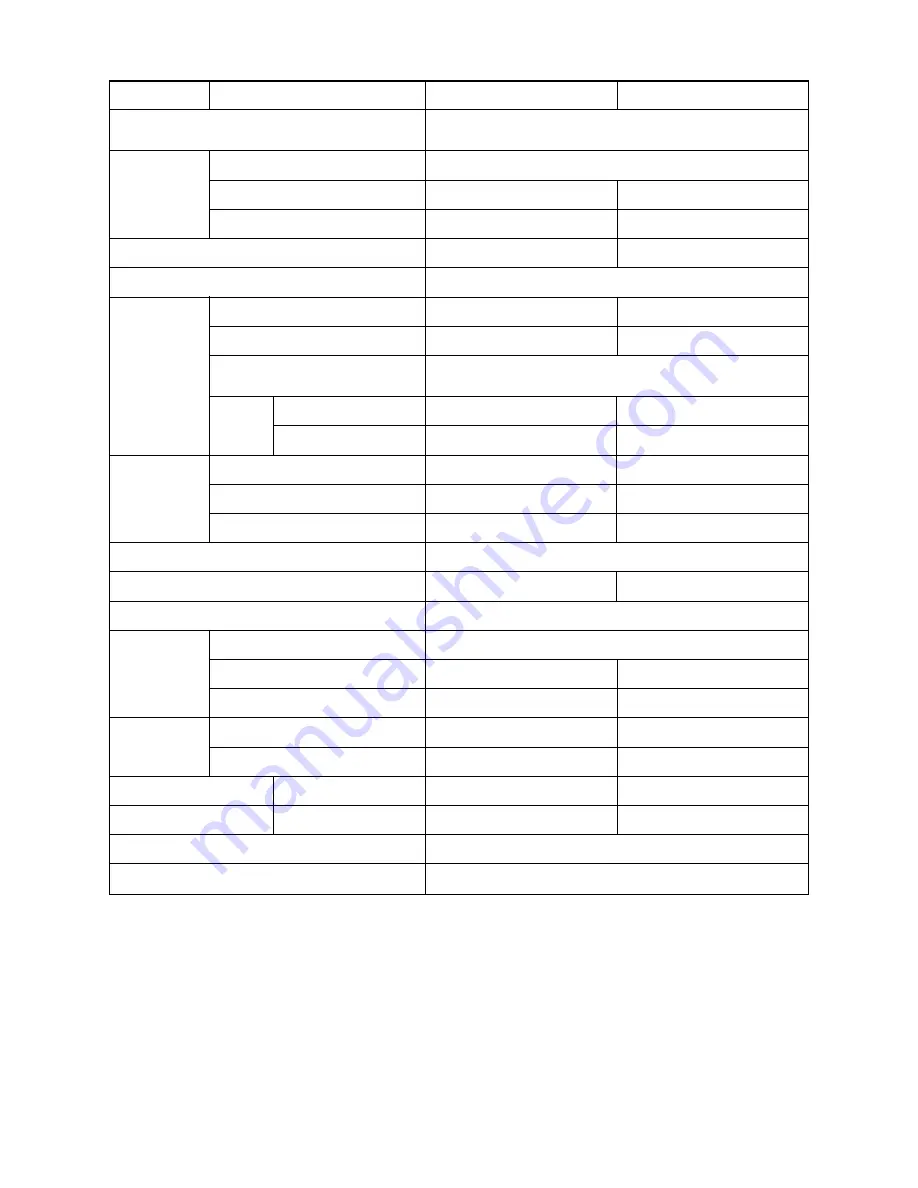

Model name

Outdoor unit

Power supply

Type

Compressor

Motor

(kW)

Pole

Refrigerant charged

(kg)

Refrigerant control

Standard length

(m)

Max. total length

(m)

Inter

Additional refrigerant charge

connecting pipe

under long piping connector

Height

Outdoor lower

(m)

difference

Outdoor higher

(m)

Height

(mm)

Outer dimension

Width

(mm)

Depth

(mm)

Appearance

Total weight

(kg)

Heat exchanger

Fan

Fan unit

Standard air flow

(m³/h)

Motor

(W)

Connecting pipe

Gas side

(mm)

Liquid side

(mm)

Sound pressure level

Cooling/Heating

(dB•A)

Sound power level

Cooling/Heating

(dB•A)

Outside air temperature, Cooling

(°C)

Outside air temperature, Heating

(°C)

RAV-SP404AT(Z)(ZG)-E

RAV-SP454AT(Z)(ZG)-E

1 phase 230V (220 – 240V) 50Hz

(Power exclusive to outdoor is required.)

Hermetic compressor

1.1

1.1

4

4

1.0

1.0

Pulse motor valve

7.5

7.5

30

30

20g/m (21m to 30m)

30

30

30

30

550

550

780

780

290

290

Silky shade (Muncel 1Y8.5/0.5)

40

40

Finned tube

Propeller fan

40

40

43

43

12.7

12.7

6.4

6.4

45 / 47

45 / 47

62 / 64

62 / 64

43 to –15°C

15 to –15°C