– 166 –

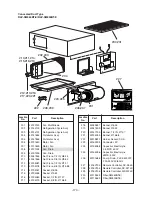

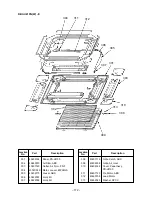

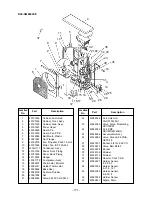

No.

Part name

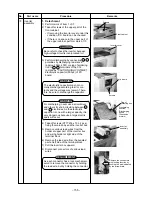

Reactor

Procedure

1) Perform works of items 1 of

and

.

2) Take off screws fixing the reactor.

(Ø4 x 10L , 2 pcs. per one reactor.

An outdoor unit has two reactors on the

partition plate.)

Remarks

Reactor

Partition plate

Screws

Positioning extrusion

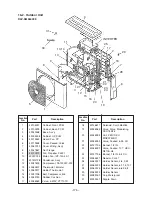

PMV body

PMV coil

Concavity

1. Detachment

1) Perform works of items 1 of

and

.

2) Remove the coil from PMV body while

pulling it upward.

2. Attachment

1) Match the positioning extrusion of the coil

surely to the concavity of PMV body to fix it.

Pulse Modulating

Valve (PMV) coil

Summary of Contents for RAV-SM560AT-E

Page 187: ......