– 22 –

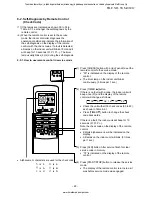

9-2. Self-Diagnosis by Remote Control

(Check Code)

(1) If the lamps are indicated as shown 00 to 03 in

Table 9-1-1, exchanger the self-diagnosis by the

remote control.

(2) When the remote control is set to the service

mode, the indoor controller diagnoses the

operation condition and indicate the information of

the self-diagnosis on the display of the remote

control with the check codes. If a fault is detected,

all lamps on the indoor unit will blink at 5 Hz and it

will beep for 10 seconds (Pi, Pi, Pi....). The timer

lamp usually blinks (5 Hz) during the self-diagnosis.

9-2-1. How to use remote control in service mode

(1) Press [CHECK] button with a tip of pencil to set the

remote control to the service mode.

•

“00” is indicated on the display of the remote

control.

•

The timer lamp on the indoor unit blinks

continuously. (5 times per 1 sec.)

(2) Press [TIMER

8

] button.

If there is no fault with a code, the indoor unit will

beep once (Pi) and the display of the remote

control will change as follows:

•

Check the unit with all 35 check codes (00 to 22).

as shown in Table 9-2-1.

•

Press [TIMER

9

] button to change the check

code backwards.

If there is a fault, the indoor unit will beep for 10

seconds (Pi, Pi, Pi...).

Note the check code on the display of the remote

control.

•

2-digits alphanumeric will be indicated on the

display.

•

All lamps on the indoor unit will blink. (5 times

per 1 sec.)

(4) Press [START/STOP] button to release the service

mode.

•

The display of the remote control returns to as it

was before service mode was engaged.

(3) Press [CLR] button. After service finish for clear

service code in memory.

•

“7F” is indicated on the display of the remote

control.

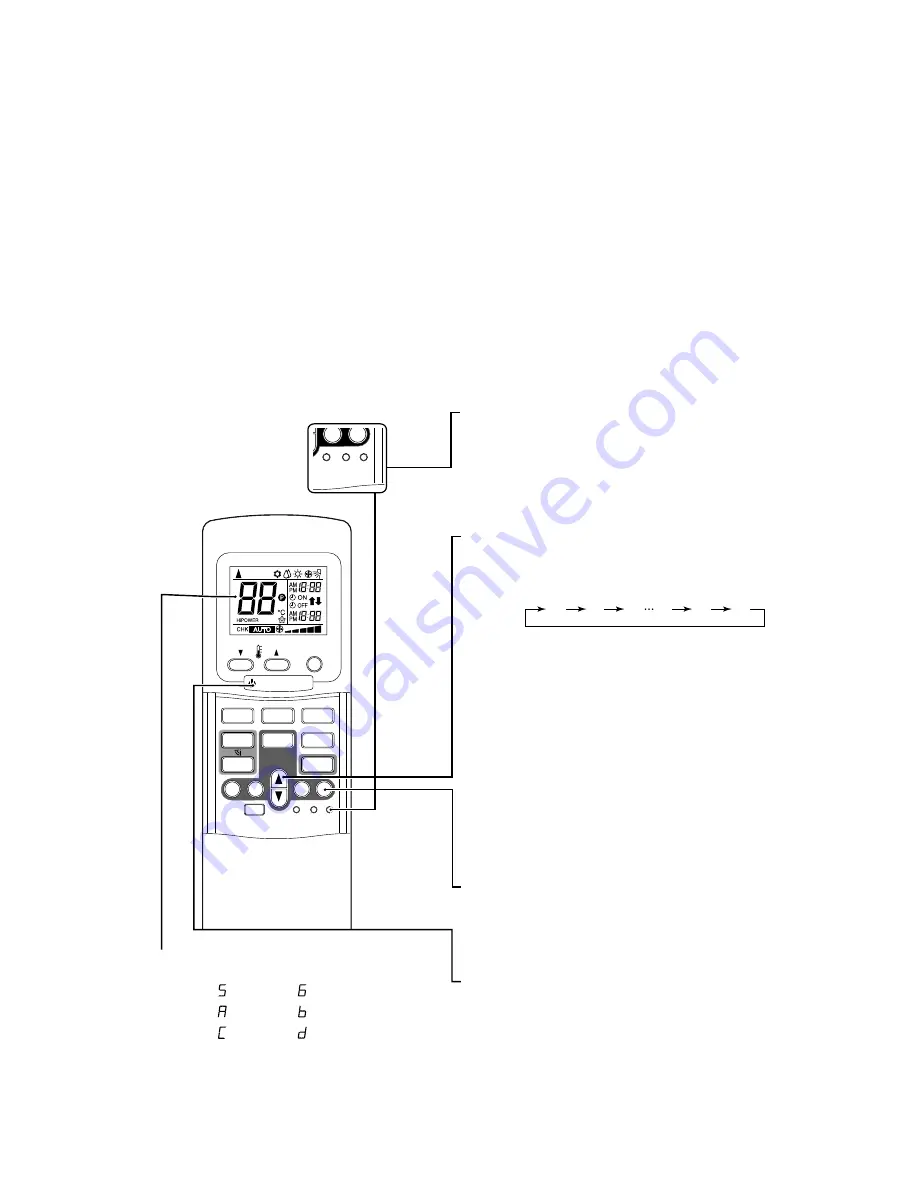

PRESET

FAN

MODE

Hi-POWER

ON

OFF

SET

CLR

ECO

AUTO

TIMER

CLOCK CHECK

RESET

FILTER

FIX

SWING

MEMO

START/STOP

A

B

AUTOA

SET

CLR

CLOCK CHECK

RESET

•

Alphanumeric characters are used for the check code.

is 5.

is 6.

is A.

is B.

is C.

is D.

00

01

1d

1E

02

22

FILE NO. SVM-06012

Toshiban lämmitys- ja jäähdytyslaitteiden jälleenmyyjä pääkaupunkiseudulla on Jäähdytinpalvelu RefGroup Oy

www.ilmalämpöpumput.com