7

90˚

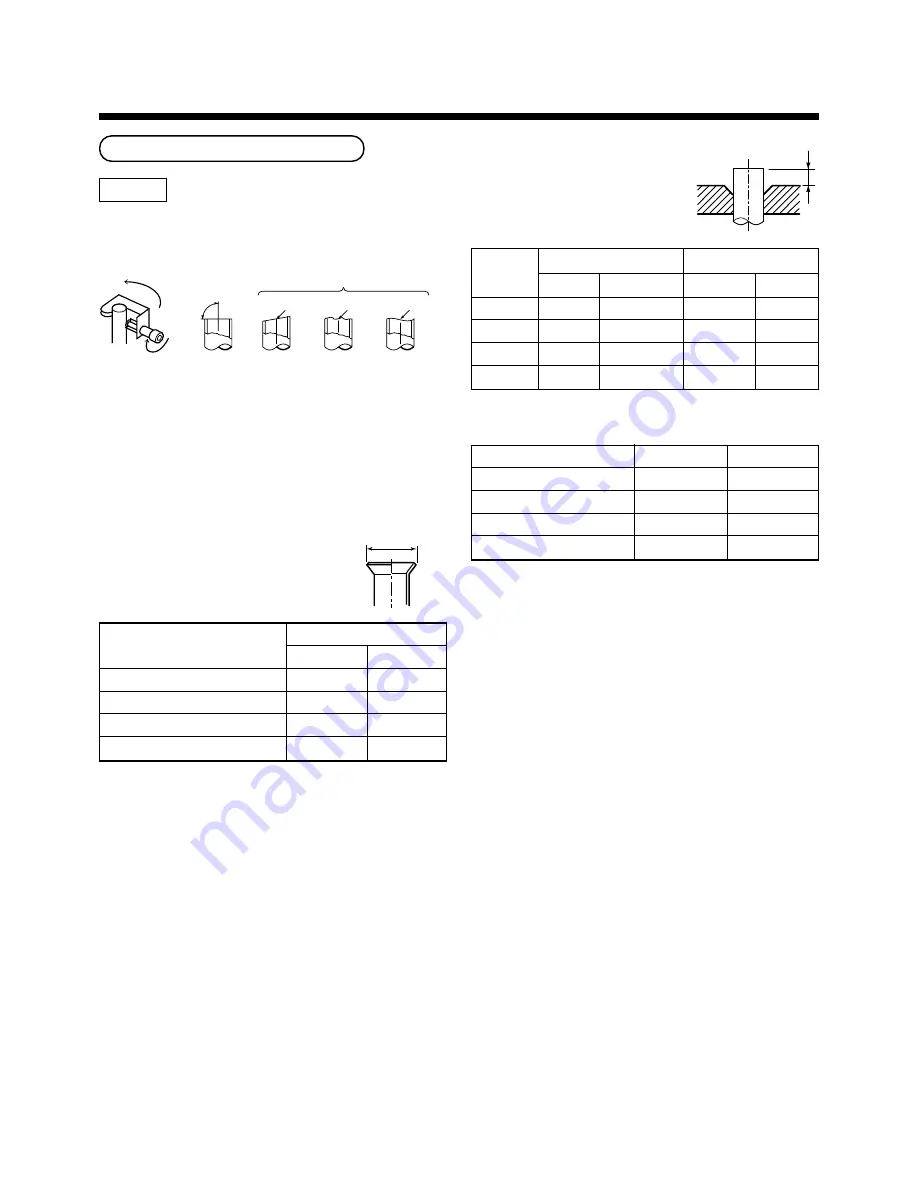

Obliquity

Roughness

Warp

NO GOOD

OK

Pipe Forming/End Positioning

Flaring

1. Cut the pipe with a pipe cutter.

4

REFRIGERANT PIPING

2. Insert a flare nut into the pipe, and flare the pipe.

As the flaring sizes of R410A differ from those of

refrigerant R22, the flare tools newly manufactured

for R410A are recommended.

However, the conventional tools can be used by

adjusting projection margin of the copper pipe.

• Flaring size : A (Unit : mm)

* In case of flaring for R410A with the conventional

flare tool, pull it out approx. 0.5 mm more than that of

R22 to adjust to the specified flare size. The copper

pipe gauge is useful for adjusting projection margin

size.

Imperial (Wing nut type)

B

• Projection margin in flaring :

B (Unit : mm)

Rigid (Clutch type)

A

R410A

R22

9.1

9.0

13.2

13.0

16.6

16.2

19.7

19.4

+0

- 0.4

Outer dia. of copper pipe

6.4

9.5

12.7

15.9

Outer dia.

of copper

pipe

6.4

9.5

12.7

15.9

R410A tool used

R410A

R22

0 to 0.5

(Same as left)

0 to 0.5

(Same as left)

0 to 0.5

(Same as left)

0 to 0.5

(Same as left)

Conventional tool used

R410A

R22

1.0 to 1.5

0.5 to 1.0

1.0 to 1.5

0.5 to 1.0

1.0 to 1.5

0.5 to 1.0

1.0 to 1.5

0.5 to 1.0

Outer dia. of copper pipe

6.4

9.5

12.7

15.9

R410A

R22

1.5 to 2.0

1.0 to 1.5

1.5 to 2.0

1.0 to 1.5

2.0 to 2.5

1.5 to 2.0

2.0 to 2.5

1.5 to 2.0

A