– 30 –

6-6-6. Handling of Existing Pipe

When using the existing pipe, carefully check it for

the following:

• Wall thickness (within the specified range)

• Scratches and dents

• Water, oil, dirt, or dust in the pipe

• Flare looseness and leakage from welds

• Deterioration of copper pipe and heat insulator

Cautions for using existing pipe

• Do not reuse the flare to prevent gas leak.

Replace it with the supplied flare nut and then

process it to a flare.

• Blow nitrogen gas or use an appropriate means to

keep the inside of the pipe clean.

If discolored oil or much residue is discharged,

wash the pipe.

• Check welds, if any, on the pipe for gas leak.

When the pipe corresponds to any of the following,

do not use it. Install a new pipe instead.

• The pipe has been open (disconnected from indoor

unit or outdoor unit) for a long period.

• The pipe has been connected to an outdoor unit

that does not use refrigerant R22, R410A or R407C.

• The existing pipe must have a wall thickness equal

to or larger than the following thickness.

• Never use any pipe with a wall thickness less than

these thicknesses due to insufficient pressure

capacity.

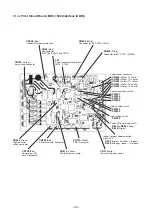

• To use an existing Ø19.1 mm pipe, set bit 3 of

SW802 (switch for existing pipe) on the P.C. board

of the outdoor unit to ON.

In this case, the heating performance may be

reduced depending on the outside air temperature

and room temperature.

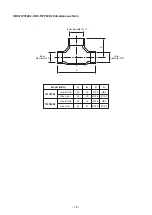

Reference outside diameter

(mm)

Ø9.5

Ø15.9

Ø19.1

Wall thickness

(mm)

0.8

1.0

1.0

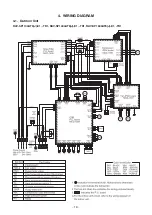

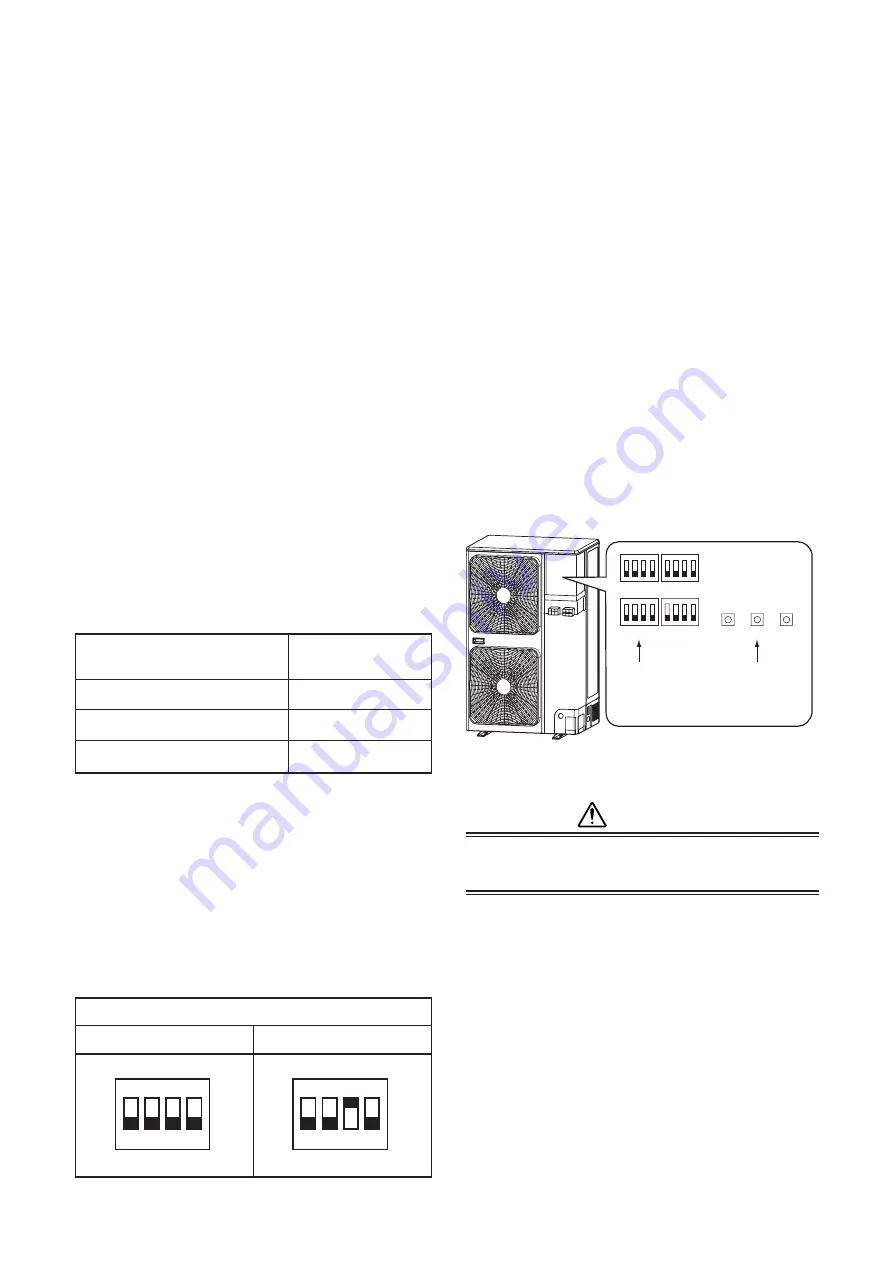

SW802

When shipped from factory

When using existing pipe

1 2 3 4

ON

1 2 3 4

ON

6-6-7. Recovery Method of Refrigerant

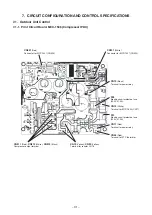

• Use the refrigerant recovery switch SW801 on the

P.C. board of the outdoor unit to recover refriger-

ant when the indoor unit or outdoor unit is moved.

Procedure

1. Turn on the power of the air conditioner.

2. Select the FAN mode for indoor unit operation

with the remote controller.

3. Set SW804 on the P.C. board of the outdoor unit

to all OFF, and then push SW801 for one second

or more.

The air conditioner enters the forced cooling

mode for up to 10 minutes.

Operation or handling the valve to recover

refrigerant during this time period.

4. Upon completion of refrigerant recovery, close

the valve and push SW801 for at least one

second to stop operation.

5. Turn off the power.

DANGER

Take care for an electric shock because the P.C.

board is electrified.

SW800 SW801 SW806

SW802

SW803

ON

1

2

3

4

ON

1

2

3

4

SW804

SW805

ON

1

2

3

4

ON

1

2

3

4

Refrigerant

recovery switch

SW801

Existing pipe

switch SW802