– 84 –

- 60 -

2

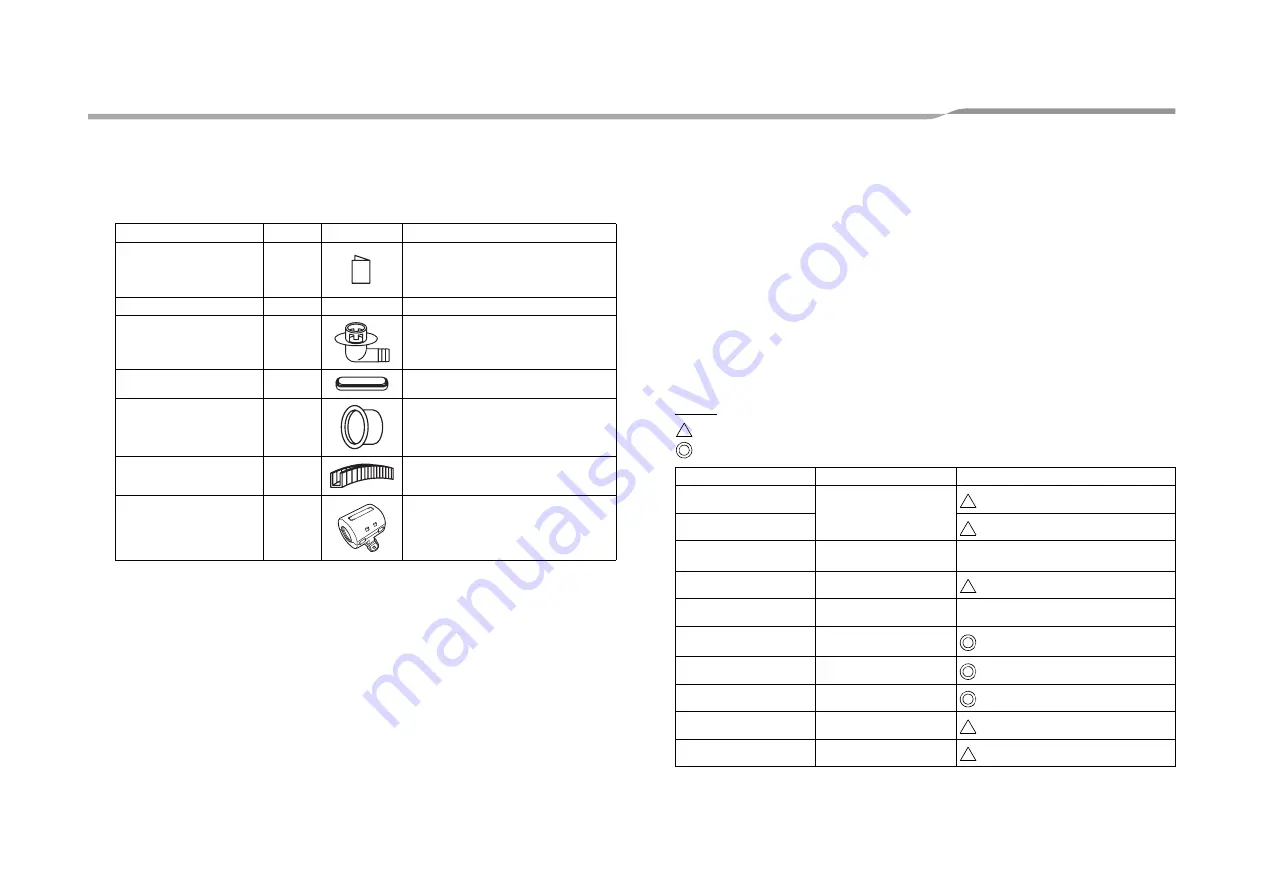

ACCESSORY PARTS AND REFRIGERANT

Accessory Parts

Part name

Q’ty

Shape

Usage

Outdoor unit installation manual

1

Hand this directly to the customer.

(For other languages that do not appear in this

Installation Manual, please refer to the enclosed

CD-R.)

CD-R

1

—

Installation manual

Drain nipple

1

Waterproof rubber cap

5

Protective bush

1

For protecting wires (pipe cover)

Guard material for passage part

1

For protecting passage part (pipe cover)

Clamp filter

1

For conforming to EMC standards

(Used for power wire)

3

INSTALLATION OF NEW REFRIGERANT AIR

CONDITIONER

• The R410A refrigerant is more susceptible to impurities such as water, oxide membranes, oils, and fats.

With the adoption of the new refrigerant, the refrigerating oil has also been changed.

Be careful not to let water, dust, conventional refrigerant, and/or conventional refrigerating oil enter the refrigerating

cycle of the new refrigerant air conditioner.

• To prevent different refrigerant or refrigerating oil from becoming mixed, the sizes of the charging port of the unit

and the installation tool connection sections are different from those of the conventional refrigerant. Accordingly, the

following exclusive tools are required for the new refrigerant R410A.

Required Tools/Equipment and Precautions for Use

Prepare the tools and equipment listed in the following table before starting the installation work.

Newly prepared tools and equipment must be used exclusively.

Legend

: Prepared newly (Use for R410A only. Do not use for refrigerant R22 or R407C etc.)

: Conventional tools/equipment are available

Tools/equipment

Use

How to use tools/equipment

Gauge manifold

Vacuuming/charging refrigerant

and operation check

Prepared newly for R410A only

Charging hose

Prepared newly for R410A only

Charging cylinder

Can not be used

Unusable (Use the refrigerant charging measure

instead.)

Gas leak detector

Gas leak check

Prepared newly

Vacuum pump

Vacuum drying

Unusable

Vacuum pump with backflow

prevention function

Vacuum drying

R22 (Conventional tools)

Flare tool

Flare machining of pipes

Usable if dimensions are adjusted.

Bender

Bending pipes

R22 (Conventional tools)

Refrigerant recovery equipment Refrigerant recovery

For R410A only

Torque wrench

Tightening flare nuts

Exclusive for Ø12.7 mm and Ø15.9 mm

EN-119

EN-120

13. INSTALLATION MANUAL