� 18 �

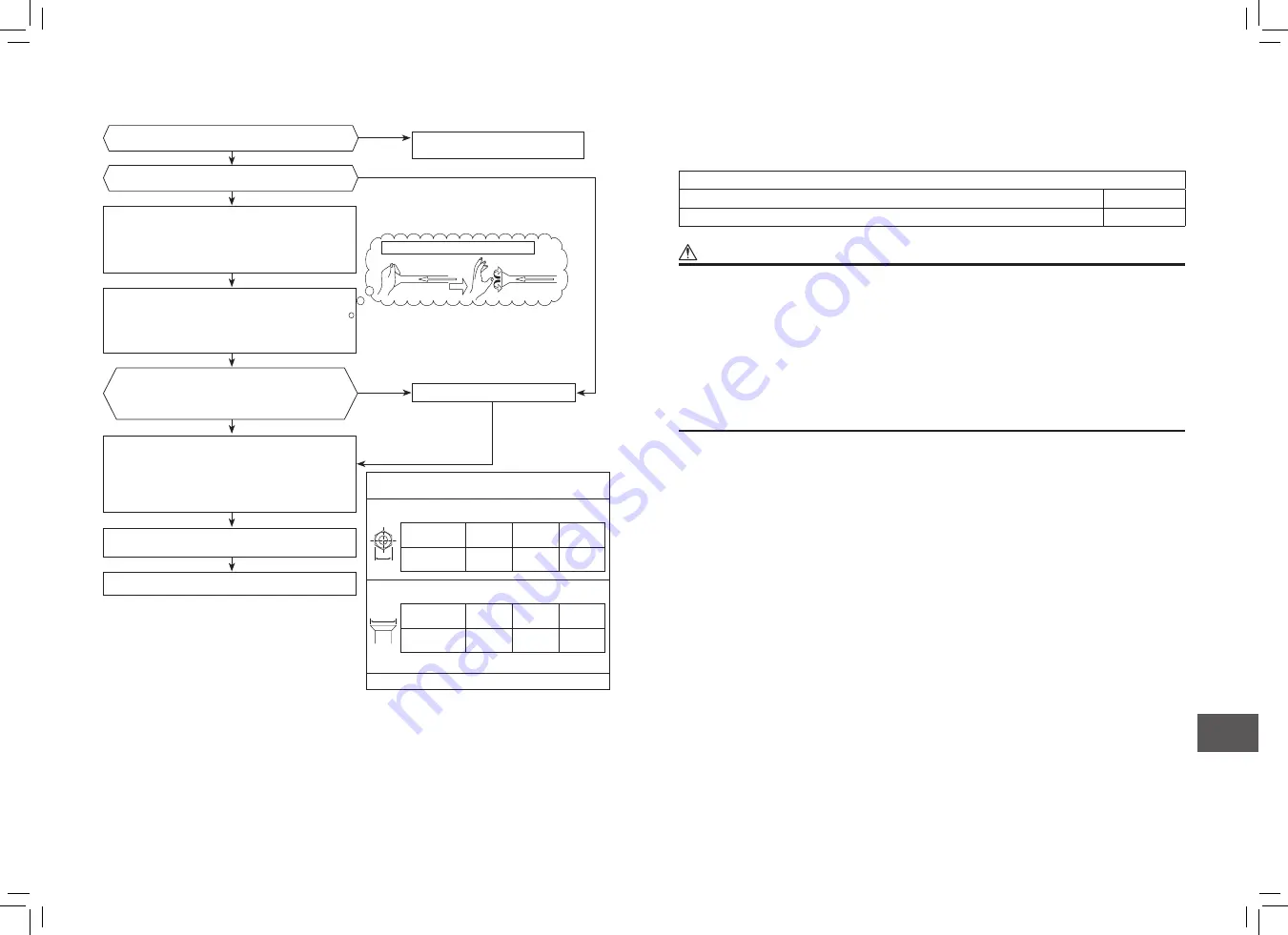

Connect the indoor / outdoor units to the existing pipe.

• Use a flare nut attached to the main unit for the

indoor / outdoor units. (Do not use the flare nut of

the existing pipe.)

• Re-machine the flare machining size to size for

R410A.

Is it possible to operate the existing air conditioner?

• Remove the existing air conditioner from the piping

and carry out flushing (nitrogen pressure 0.5 MPa)

to remove any remains inside of the pipe.

Note:

In case of twin pipes, also be sure to flush the

branching pipe.

Was largely discolored oil or a large quantity of

remains discharged?

(When the oil deteriorates, the color of the oil

changes to a muddy or black color.)

Nitrogen gas pressure 0.5 MPa

Clean the pipes or use new pipes.

(If there is discharge of remains, it is judged that a

large quantity of remains are present.)

NO

NO

YES

YES

YES

NO

Existing pipes: Cannot be used.

• Use new pipes.

Are there scratches or dents on the existing pipes?

• After the existing air conditioner is operated in

cooling mode for approx. 30 minutes or longer,*

recover the refrigerant.

• For cleaning the pipes and recovering oil

• Refrigerant recovery: Pump down method

Test run

• (Airtight test), Vacuum dry, Refrigerant charge, Gas

leak check

15

Specifications

This product contains fluorinated greenhouse gases covered by the Kyoto Protocol

Chemical Name of Gas

R410A

Global Warming Potential (GWP) of Gas

1,975

CAUTION

1. Paste the enclosed refrigerant label adjacent to the charging and/or recovering location.

2. Clearly write the charged refrigerant quantity on the refrigerant label using indelible ink. Then, place the

included transparent protective sheet over the label to prevent the writing from rubbing off.

3. Prevent emission of the contained fluorinated greenhouse gas. Ensure that the fluorinated greenhouse

gas is never vented to the atmosphere during installation, service or disposal. When any leakage of the

contained fluorinated greenhouse gas is detected, the leak shall be stopped and repaired as soon as

possible.

4. Only qualified service personnel are allowed to access and service this product.

5. Any handling of the fluorinated greenhouse gas in this product, such as when moving the product or

recharging the gas, shall comply under (EC) Regulation No. 842/2006 on certain fluorinated greenhouse

gases and any relevant local legislation.

6. Periodical inspections for refrigerant leaks may be required depending on European or local legislation.

7. Contact dealers, installers, etc., for any questions.

EN

35-EN

36-EN

Piping necessary to change the flare nut / machining

size due to pipe compression

1) Flare nut width: H

(in (mm))

H

Copper pipe

outer diameter

1/4”(6.4)

3/8”(9.5)

1/2”(12.7)

For

R410A

0.67”(17)

0.87”(22)

1.02”(26)

2) Flare machining size: A

(in (mm))

A

Copper pipe

outer diameter

1/4”(6.4)

3/8”(9.5)

1/2”(12.7)

For

R410A

0.36”(9.1) 0.52”(13.2) 0.65”(16.6)

Becomes a little larger for R410A

Do not apply refrigerator oil to the flare surface.

1131701101-00_S01_297x210_60p_S_p70_220426.indd 18

26/4/2565 11:41:11