– 3

1

–

FILE NO. SVM-13047

Gauge manifold

]

n

o

h

p

i

s

t

u

o

h

t

i

w

r

e

d

n

i

l

y

C

[

]

n

o

h

p

i

s

h

t

i

w

r

e

d

n

i

l

y

C

[

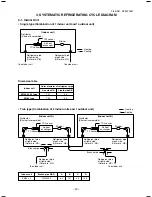

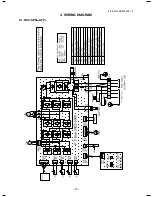

OUTDOOR unit

Gauge manifold

OUTDOOR unit

Refrigerant

cylinder

Electronic

balance

Refriger

ant

cylinder

Electronic

balance

Siphon

1) Be sure to make setting so that

liquid

can be charged.

2) When using a cylinder equipped with a siphon, liquid can be charged without turning it upside down.

It is necessary for charging refrigerant under condition of liquid because R410A is mixed type of refrigerant.

Accordingly, when charging refrigerant from the refrigerant cylinder to the equipment, charge it turning the

cylinder upside down if cylinder is not equipped with siphon.

R410A refrigerant is HFC mixed refrigerant.

Therefore, if it is charged with gas, the

composition of the charged refrigerant changes

and the characteristics of the equipment varies.

Fig. 6-4-2

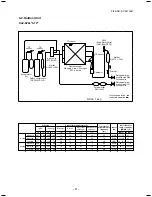

6-5. Brazing of Pipes

6-5-1. Materials for Brazing

1. Silver brazing filler

Silver brazing filler is an alloy mainly composed

of silver and copper.

It is used to join iron, copper or copper alloy, and

is relatively expensive though it excels in solder-

ability.

2. Phosphor bronze brazing filler

Phosphor bronze brazing filler is generally used

to join copper or copper alloy.

3. Low temperature brazing filler

Low temperature brazing filler is generally called

solder, and is an alloy of tin and lead.

Since it is weak in adhesive strength, do not use

it for refrigerant pipes.

1) Phosphor bronze brazing filler tends to react

with sulfur and produce a fragile compound

water solution, which may cause a gas

leakage. Therefore, use any other type of

brazing filler at a hot spring resort, etc., and

coat the surface with a paint.

2) When performing brazing again at time of

servicing, use the same type of brazing filler.

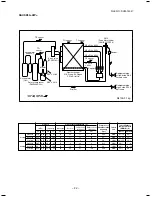

6-5-2. Flux

1. Reason why flux is necessary

s

By removing the oxide film and any foreign

matter on the metal surface, it assists the flow

of brazing filler.

s

In the brazing process, it prevents the metal

surface from being oxidized.

s

By reducing the brazing filler's surface tension,

the brazing filler adheres better to the treated

metal.

SVM-12085_001-050.indd 32

SVM-12085_001-050.indd 32

12/06/12 11:06 AM

12/06/12 11:06 AM

Summary of Contents for RAV-SP564ATP-A

Page 17: ... 17 FILE NO SVM 13047 2 CONSTRUCTION VIEWS EXTERNAL VIEWS 2 1 RAV SP56 ATP ...

Page 18: ... 18 FILE NO SVM 13047 2 2 RAV SP80 ATP ...

Page 23: ... 23 FILE NO SVM 13047 1 4 WIRING DIAGRAM 4 1 RAV SP56 ATP ...

Page 24: ... 24 FILE NO SVM 13047 4 2 RAV SP80 ATP ...

Page 100: ... 100 FILE NO SVM 13047 1 11 1 RAV SP564ATP A 11 EXPLODED VIEWS AND PARTS LIST ...

Page 104: ... 104 FILE NO SVM 13047 11 2 RAV SP804ATP A ...

Page 109: ......