EN-16

EN-15

8

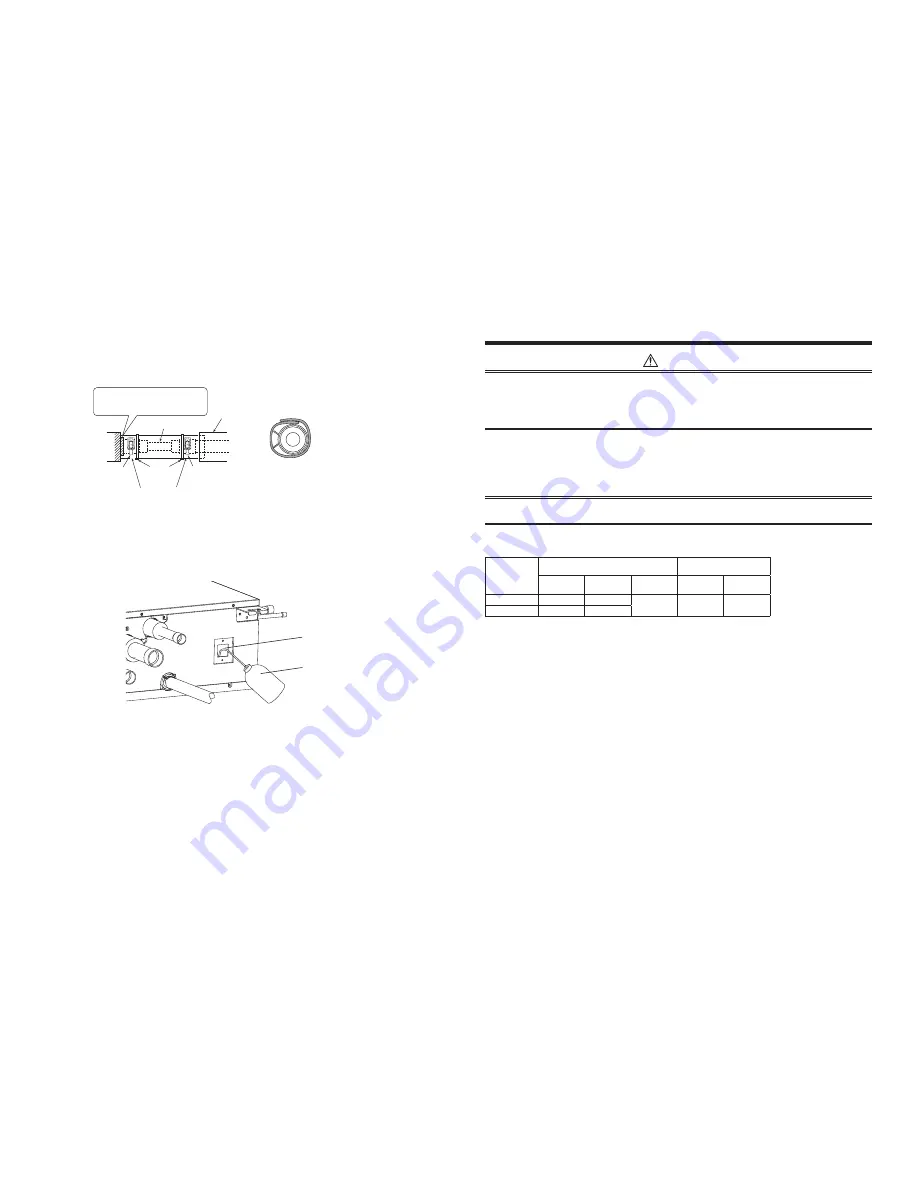

Heat insulating process

• Using the attached drain hose heat insulator, lap the connecting section and the drain hose without clearance,

and then tighten with two handing band so that heat insulator does not open.

• Covering the attached drain hose heat insulator, lap the heat insulator (locally procured) to the drain pipe without

clearance.

Lap covering connecting section

between drain pan and drain hose.

Heat insulator

(locally procured)

Drain hose

Drain

pan

Hose band

Attached heat insulator

Binding band

Hose band

Lap the attached heat

insulation so that the

one end is put on

the other end at the

upper side.

* Tighten the banding band so that attached

heat insulator is not pushed excessively.

* Fasten the binding bands in such a manner as to not

squeeze the attached insulating material excessively.

Check the draining

After installation work, check that water drain is properly performed and water does not leak from the connect the

pipes.

Check port

Plastic container

(to pour water)

6

REFRIGERANT PIPING

WARNING

If refrigerant gas has leaked during the installation work, ventilate the room immediately.

If the leaked refrigerant gas comes in contact with

fi

re, noxious gas may be generated.

After the installation work, con

fi

rm that refrigerant gas does not leak.

If refrigerant gas leaks into the room and

fl

ows near a

fi

re source, such as a fan heater, cooking stove or heating

unit, noxious gas may be generated.

Permissible pipe length and permissible height difference

The length of a connection pipe to the indoor unit should be 50m or less.

For details, refer to the installation manual attached to the outdoor unit.

REQUIREMENT

When the refrigerant pipe is long, set the support brackets to

fi

x the pipe at intervals of 2.5 to 3m.

If the pipe is not

fi

xed, noise may be generated.

Connection pipe size of Flow Selector unit (default)

RBM-Y1801****

Outdoor unit side

(Upstream)

Indoor unit side

(downstream)

Suction gas

pipe

Discharge

gas pipe

Liquid pipe

Gas pipe

Liquid pipe

F4PE

Ø38.1

Ø28.6

Ø22.2

Ø15.9

Ø9.5

F6PE

Ø38.1

Ø28.6