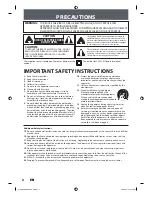

1. Precautions

1-1 Safety Precautions

1-1

1) Before returning an instrument to the customer,

always make a safety check of the entire instrument,

including, but not limited to, the following items:

(1) Be sure that no built-in protective devices are

defective or have been defeated during servicing.

(1)Protective shields are provided to protect both

the technician and the customer. Correctly replace

all missing protective shields, including any

removed for servicing convenience.

(2)When reinstalling the chassis and/or other as-

sembly in the cabinet, be sure to put back in place

all protective devices, including, but not limited to,

nonmetallic control knobs, insulating fish papers,

adjustment and compartment covers/shields, and

isolation resistor/capacitor networks. Do not oper-

ate this instrument or permit it to be operated with-

out all protective devices correctly installed and

functioning.

(2) Be sure that there are no cabinet openings through

which adults or children might be able to insert

their fingers and contact a hazardous voltage. Such

openings include, but are not limited to, excessive-

ly wide cabinet ventilation slots, and an improper-

ly fitted and/or incorrectly secured cabinet back

cover.

(3) Leakage Current Hot Check-With the instrument

completely reassembled, plug the AC line cord

directly into a 230V(220V ~ 240V) AC outlet. (Do

not use an isolation transformer during this test.)

Use a leakage current tester or a metering system

that complies with American National Standards

institute (ANSI) C101.1 Leakage Current for

Appliances and Underwriters Laboratories (UL)

1270 (40.7). With the instrument’s AC switch first in

the ON position and then in the OFF position, mea-

sure from a known earth ground (metal water pipe,

conduit, etc.) to all exposed metal parts of the

instrument (antennas, handle brackets, metal cabi-

nets, screwheads, metallic overlays, control shafts,

etc.), especially any exposed metal parts that offer

an electrical return path to the chassis.

Any current measured must not exceed 0.5mA.

Reverse the instrument power cord plug in the out-

let and repeat the test. See Fig. 1-1.

Any measurements not within the limits specified

herein indicate a potential shock hazard that must

be eliminated before returning the instrument to

the customer.

Fig. 1-1 AC Leakage Test

(4) Insulation Resistance Test Cold Check-(1) Unplug

the power supply cord and connect a jumper wire

between the two prongs of the plug. (2) Turn on the

power switch of the instrument. (3) Measure the

resistance with an ohmmeter between the

jumpered AC plug and all exposed metallic cabinet

parts on the instrument, such as screwheads,

antenna, control shafts, handle brackets, etc. When

an exposed metallic part has a return path to the

chassis, the reading should be between 1 and 5.2

megohm. When there is no return path to the chas-

sis, the reading must be infinite. If the reading is

not within the limits specified, there is the possibil-

ity of a shock hazard, and the instrument must be

repaired and rechecked before it is returned to the

customer. See Fig. 1-2.

Fig. 1-2 Insulation Resistance Test

DEVICE

UNDER

TEST

(READING SHOULD

NOT BE ABOVE

0.5mA)

LEAKAGE

CURRENT

TESTER

EARTH

GROUND

TEST ALL

EXPOSED METER

SURFACES

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

2-WIRE CORD

Antenna

Terminal

Exposed

Metal Part

ohm

ohmmeter

Summary of Contents for RD-XS24SB

Page 10: ...Product Specification 2 4 MEMO ...

Page 12: ...3 2 Software Update MEMO ...

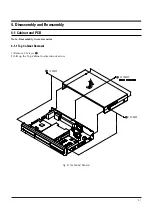

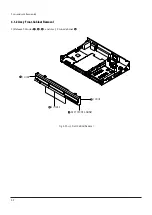

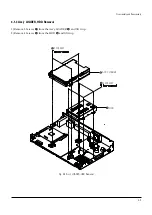

Page 20: ...4 8 Disassembly and Reaasembly MEMO ...

Page 34: ...Troubleshooting 5 14 MEMO ...

Page 35: ...6 1 6 Exploded View and Parts List 6 1 Cabinet Assembly Page 6 2 ...

Page 38: ...Exploded Views and Parts List 6 4 MEMO ...

Page 50: ...Electrical Parts List 7 12 MEMO ...

Page 160: ...Operating Instructions 12 110 MEMO ...

Page 173: ...1 1 SHIBAURA 1 CHOME MINATO KU TOKYO 105 8001 JAPAN ...

Page 177: ...Block Diagrams 8 3 8 2 Digital Block Diagram ...

Page 180: ...Block Diagrams 8 6 8 5 AIC01 MSP3417 Block Diagram ...

Page 181: ...Block Diagrams 8 7 8 6 AIC02 AIC07 MC14052 Block Diagram ...

Page 182: ...Block Diagrams 8 8 8 7 AIC03 AK5357 Block Diagram ...

Page 183: ...Block Diagrams 8 9 8 8 AIC04 PCM1753 Block Diagram ...

Page 184: ...Block Diagrams 8 10 8 9 KIC01 PT6961 Block Diagram ...

Page 185: ...Block Diagrams 8 11 8 10 MIC01 78F4225 Block Diagram ...

Page 187: ...Block Diagrams 8 13 8 12 SIC01 MM1647 Block Diagram ...

Page 188: ...Block Diagrams 8 14 8 13 VIC01 74HC4051 Block Diagram ...

Page 189: ...Block Diagrams 8 15 8 14 VIC05 MM1568 Block Diagram ...

Page 190: ...Block Diagrams 8 16 MEMO ...

Page 191: ...9 Wiring Diagram 9 1 ...

Page 192: ...Wiring Diagram 9 2 MEMO ...

Page 194: ...PCB Diagrams 10 2 10 1 S M P S PCB COMPONENT SIDE ...

Page 195: ...PCB Diagrams 10 3 CONDUCTOR SIDE ...

Page 196: ...PCB Diagrams 10 4 10 2 Main PCB COMPONENT SIDE ...

Page 198: ...PCB Diagrams 10 6 10 3 Jack PCB COMPONENT SIDE ...

Page 199: ...PCB Diagrams 10 7 CONDUCTOR SIDE ...

Page 200: ...PCB Diagrams 10 8 10 4 Key PCB COMPONENT SIDE CONDUCTOR SIDE ...

Page 202: ...Schematic Diagrams 11 2 11 1 S M P S SMPS PCB ...

Page 203: ...Schematic Diagrams 11 3 11 2 Main Main PCB ...

Page 204: ...Schematic Diagrams 11 4 11 3 Audio Jack PCB ...

Page 205: ...Schematic Diagrams 11 5 11 4 Video Jack PCB ...

Page 206: ...Schematic Diagrams 11 6 11 5 AV switch Scart Jack PCB ...

Page 207: ...Schematic Diagrams 11 7 11 6 Tuner Front in Connection Jack PCB ...

Page 208: ...Schematic Diagrams 11 8 11 7 Micom Jack PCB ...

Page 209: ...Schematic Diagrams 11 9 11 8 Key Key PCB ...

Page 210: ...Schematic Diagrams 11 10 MEMO ...