Selection of Main Circuit Wiring Equipment and Standard Cable Sizes (cont'd)

Notes:

1.) Contacts used to connect drive terminals should be capable of switching low current

signals (i.e. 5 mA).

2.) The drive has internal motor overload protection which has been functionally certified by

Underwriters Laboratories Inc. and no additional external motor overload protection is required

when used to drive a single motor load (see 1996 NEC Article 430-32 and 430-39).

3.) When wiring with parallel conductors, the conductors should be kept together in phase sets to

avoid heating the surrounding metal by induction. Install U1, V1, W1 conductors in one conduit

and parallel conductors U2, V2, W2 in another conduit. The ground conductor must be run in the

same conduit. See 1996 NEC Article 300-20(a), 310-4, 310-5. Size the grounding conductor in

accordance with 1996 NEC Table 250-95.

4) Twisted pair wires should be used for external meters connected to AM and FM terminals.

5) For multiple motor applications, a thermal-magnetic circuit breaker must be installed between

the drive and each motor (even though the drive has has built-in overload protection). The thermal

circuit is for overload sensing and the magnetic coil is for abnormal conditions such as short circuits.

Select the MCCB (molded case circuit breaker) in accordance with 1996 NEC Article 430-51 through

430-53, 430-152, and 240-6.

17

TOSHIBA

Grounding

The drive must be grounded in accordance with Article 250 of the National Electrical Code or Section 10

of the Canadian Electrical Code, Part I and the grounding conductor should be sized in accordance with

1996 NEC Table 250-95 or CEC, Part I Table 16. See Installation Safety Precautions notes 7 and 14.

Motor Selection

1) Exceeding the peak voltage rating or the rise time allowable of the motor insulation system will

reduce the life expectancy. To insure good motor insulation life, consult with the motor supplier to

determine motor insulation ratings and allowable maximum output lead distance. Long lead lengths

between the motor and the drive may require filters to be added to the drive output.

2) Bearing Considerations:

Motors operating from adjustable speed drive power sources tend to operate at higher

temperatures which may increase the need for more frequent lubrication cycles.

C A U T I O N

Conduit is not a suitable ground for the inverter.

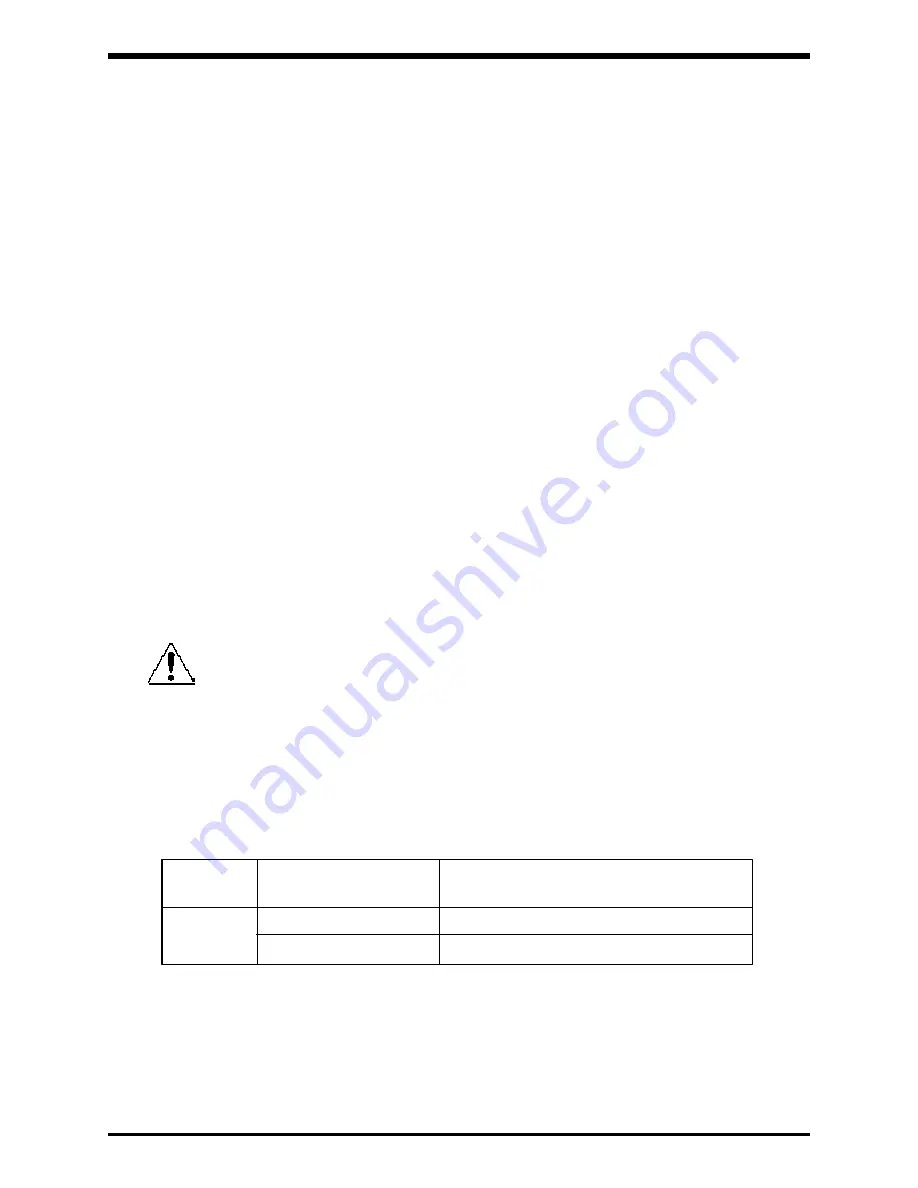

AC Motor

Voltage

PWM Carrier

Frequency

NEMA MG-1-1998 Section IV

Part 31 Compliant Motors

Suggested Maximum Output Lead Distance

575 V

< = 5 kHz

> 5 kHz

200 ft.

100 ft.

1

2

For lead lengths that exceed suggested maximum contact your local distributor or Toshiba for

additional application assistance.

Toshiba EQP III, III-XS & EQP III-841 motors incorporate an insulation system that is in

compliance with NEMA MG-1-1998 Section IV Part 31.

2

1