– 16 –

0

–1

ON

OFF

ON

OFF

ON

ON

ON

(Room temp. – Set temp.)

4-way valve

(RY04)

Outdoor fan

(RY03)

OPERATION

display

Compressor

(RY01)

Common relay

(RY02)

(Room temp. – Set temp.)

0

-1

-2

-3

-4

Set

temp.

MED

RY01 OFF

MED(-)

LOW(+)

LOW

FAN

Manual

AUTO

According

to the set

position

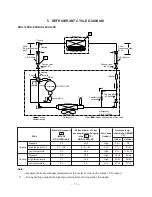

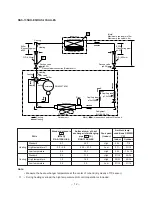

7-4. HEAT Operation

(MODE of the remote control : HEAT)

(1) Relays compressor 4-way valve, outdoor fan and

operation display are controlled as shown in Fig.

7-4-1.

Fig. 7-4-1

(2) Relays RY01 and RY02 are turned on to energize

the outdoor unit, and a heat operation is carried

out. The indoor fan motor operates as shown in

Fig. 7-4-2, when the FAN is set to AUTO.

The motor operates with a constant air volume as

listed in Table 7-1-1, when the FAN is set to LOW,

MED, or HIGH.

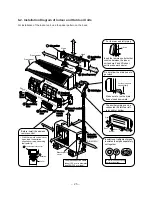

Fig. 7-4-2

(3) Once the setting is made, the operation mode is

memorized in the microcomputer so that the same

operation can be effected thereafter simply by

pushing the START/STOP button.

7-4-1. Louver Control

(1) By pushing the SET button of the remote control

during the operation, the louver can be set to the

desired position.

(2) When the AUTO button is pushed, the louver ver-

tically swings within range of 25deg.

And the louver position is stored in the microcom-

puter, and at the next operation, the louvers will be

set to the stored position automatically at the next

operation.

7-4-2. Cool Airflow Control

(1) If the indoor heat-exchanger temperature detected

by the indoor heat-exchanger sensor is 20°C or

below, the indoor fan stops and if the temperature

rises to 25°C or above, the fan is restarted.

Details are in 7-10.

Summary of Contents for SRAS-13SKH-ES

Page 53: ... 53 9 4 2 P C Board Layout Bottom View Top View ...

Page 68: ......