8

5

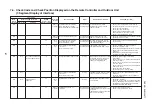

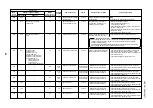

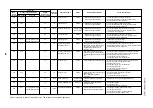

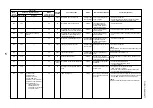

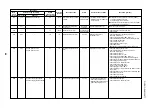

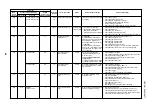

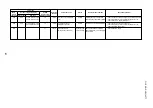

Check code

Main

remote

controller

H02

H03

H04

H06

H07

Outdoor 7-segment display

Check code

Sub-code

H02

01: Compressor 1 side

02: Compressor 2 side

H03

01: Compressor 1 side

02: Compressor 2 side

H04

—

H06

—

H07

—

AI-NET

central control

remote controller

1d

17

44

20

d7

Detected

position

IPDU

IPDU

I/F

I/F

I/F

Check code name

Compressor error (lock)

MG-SW error

OCR operation

Current detection circuit

system error

Compressor 1 case

thermo operation

Low-pressure protective

operation

Protection for oil level

drop detection

Status

All stop

All stop

All stop

All stop

All stop

Error detection condition

Over-current

was detected several

seconds after header compressor

had started.

While header compressor stopped,

current flowed more than the

specified current and was detected.

Compressor 1 case thermostat

performed protective operation.

Low-pressure Ps detected operation

lower than 0.02MPa.

The operating compressor detected

oil shortage continuously for 2 hours.

Check item (position)

• Check compressor error.

• Check power voltage. (AC380 –10%, 415V +10%).

• Check cable of compressor and phase-missing.

• Check connector/terminal connection on IPDU P.C. board.

• Check conduction of case heater.

(Check activation error due to liquid stagnation in compressor.)

• Check outdoor P.C. board (IPDU) error.

• Check outdoor MG-SW or OCR.

• Check wiring of current detection circuit system.

• Check outdoor P.C. board (IPDU) error.

• Check compressor 1 case thermo circuit.

(Connector, wire, P.C. board)

• Check full opening of service valve. (Gas and liquid side)

• Check outdoor PMV clogging. (PMV1, 2)

• Check SV41 circuit leakage.

• Check miscabling/misinstallation of SV41 and SV42.

• Check valve open status of indoor PMV.

• Check compressor error.

• Check 4-way valve error.

• Check refrigerant shortage.

• Check full opening of service valve. (Gas and liquid side)

• Check outdoor PMV clogging. (PMV1, 2)

• Check SV41 circuit and SV42 circuit error.

• Check low-pressure Ps sensor error.

• Check indoor air filter clogging.

• Check valve open of indoor PMV.

• Check refrigerant pipe clogging.

• Check outdoor fan operation. (In heating mode)

• Check refrigerant shortage.

<Check all the outdoor units in the corresponding line.>

• Check full opening of service valve of balance pipe.

• Check connection and installation of TK1, TK2, TK3, and TK4 sensors.

• Check characteristics of TK1, TK2, TK3, and TK4 resistance values.

• Check gas leak and oil leak in the same line.

• Check refrigerant stagnation in compressor.

• Check error of SV3A, SV3B, SV3C, SV3D, and SV3E valves.

• Check clogging of oil separator oil return circuit.

• Check clogging of oil-equation circuit.

MG-SW : Magnet Switch

OCR

: Over-current Relay

FILE NO. SVM-1

40

77