IF08CZ10 April, 2019

- 57 -

DRIVE INSTALLATION DRAWINGS (cont’d)

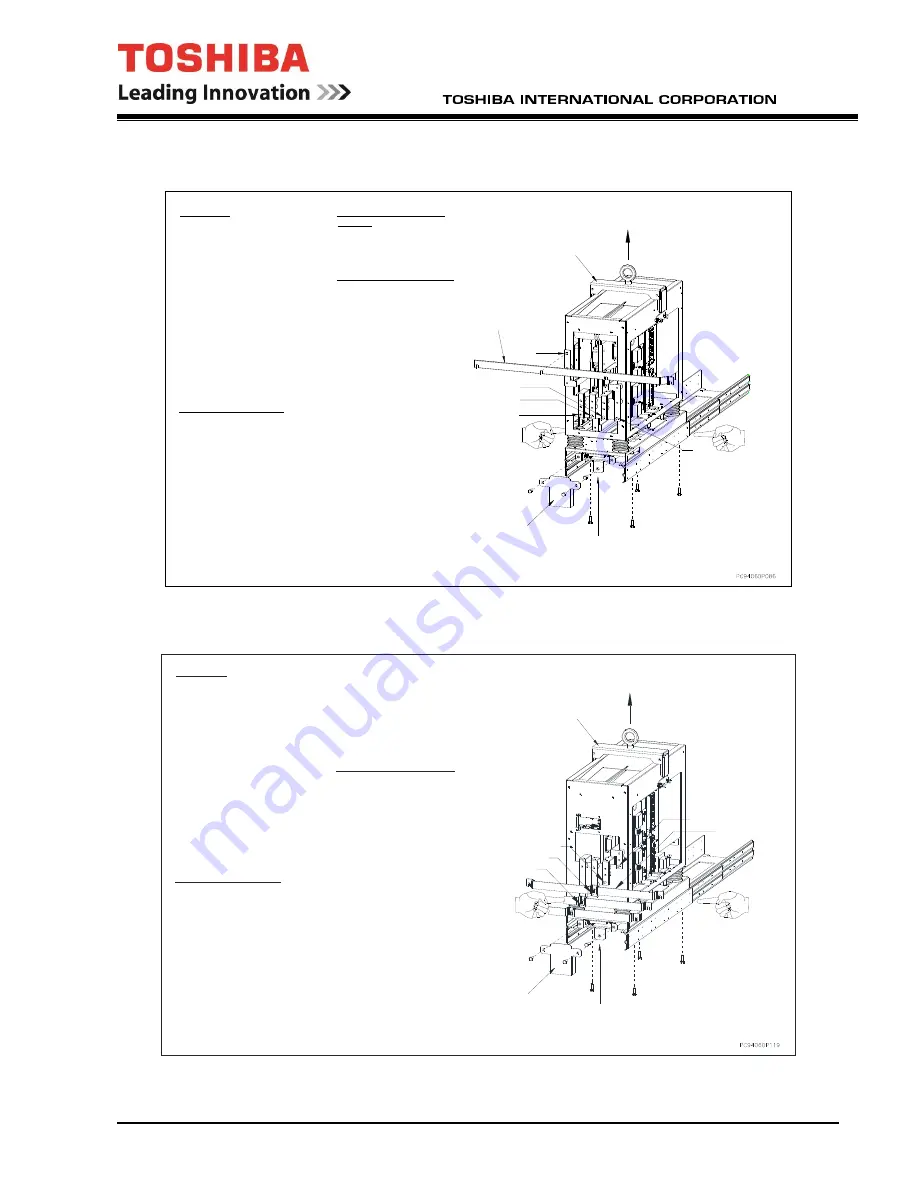

Frame 0 4160V module lifting and installation

WARNINGS

Disconnect power and wait 15

minutes to ensure capacitors are

discharged before performing

inspection or maintenance.

Improper handling of the fiber

optic cables and connectors may

cause drive failure due to

problems transmitting signals.

Take care not to disturb fiber

optic cables when handling

power module.

Use module lifting attachment

GCI6720G055 and a lifting device

rated 250 lbs minimum for

removal and installation of

modules.

Power Module Removal

1. Disconnect and remove AC

neutral bus.

2. Disconnect power cables

ACL, P, C & N.

3. Remove control wiring

cover (two "A" bolts)

4. Disconnect control signal

cable and 120VAC supply

cable from module.

5. Free slide tray by

removing bolt "B".

6. Pull slide tray out until

slides lock.

7. Remove four "C" bolts

which secure module to

tray.

Power Module Installation

1. Pull slide tray out until

slides lock.

2. Using module lifting

attachment and lifter, place

module on tray.

3. Secure module to tray with

four "C" bolts.

4. Press slide release buttons

and slide module into

compartment (use caution).

5. Reinstall bolt "B" to

secure tray in position.

6. Reconnect control signal

cable and 120VAC supply

cable to module

connectors.

7. Reinstall control wiring

cover and secure with two

"A" bolts.

8. Reconnect power cables

ACL, P, C & N.

9. Reinstall AC neutral bus.

10. Torque all power

connections (5/16-18 hdwr)

to 10-15 ft-lbs.

Power Module Removal

(cont'd)

8. Using module lifting

attachment and lifter,

lift module from tray.

A

A

B

C

C

C

C

AC NEUTRAL BUS

PINCH AREA

USE CAUTION

PINCH AREA

USE CAUTION

CONTROL WIRING

COVER

LIFTING ATTACHMENT

LIFT HERE

N

C

P

ACN

ACL

CONTROL SIGNAL &

120VAC CABLES

PRESS BUTTON

(INSIDE OF DRAWER)

TO SLIDE TRAY BACK

PRESS BUTTON

(INSIDE OF DRAWER)

TO SLIDE TRAY BACK

Frame 0 2400V module lifting and installation

WARNINGS

Disconnect power and wait 15

minutes to ensure capacitors are

discharged before performing

inspection or maintenance.

Improper handling of the fiber

optic cables and connectors may

cause drive failure due to

problems transmitting signals.

Take care not to disturb fiber

optic cables when handling

power module.

Use module lifting attachment

GCI6720G055 and a lifting device

rated 250 lbs minimum for

removal and installation of

modules.

A

A

B

C

C

C

C

PINCH AREA

USE CAUTION

PINCH AREA

USE CAUTION

CONTROL WIRING

COVER

LIFTING ATTACHMENT

LIFT HERE

N

C

P

ACL

CONTROL SIGNAL &

120VAC CABLES

PRESS BUTTON

(INSIDE OF DRAWER)

TO SLIDE TRAY BACK

PRESS BUTTON

(INSIDE OF DRAWER)

TO SLIDE TRAY BACK

BUS BAR (3)

Power Module Removal

1. Disconnect power cables

ACL, P, C & N (P, C & N on

right-hand module only).

2. Disconnect and remove bus

bars P, C & N.

3. Remove control wiring

cover (two "A" bolts)

4. Disconnect control signal

cable and 120VAC supply

cable from module.

5. Free slide tray by

removing bolt "B".

6. Pull slide tray out until

slides lock.

Power Module Installation

1. Pull slide tray out until

slides lock.

2. Using module lifting

attachment and lifter, place

module on tray.

3. Secure module to tray with

four "C" bolts.

4. Press slide release buttons

and slide module into

compartment (use caution).

5. Reinstall bolt "B" to

secure tray in position.

6. Reconnect control signal

cable and 120VAC supply

cable to module

connectors.

7. Reinstall control wiring

cover and secure with two

"A" bolts.

8. Reinstall bus bars P, C & N.

9. Reconnect power cables

ACL, P, C & N (P, C & N on

right-hand module only).

10. Torque all power

connections (5/16-18 hdwr)

to 10-15 ft-lbs.

Summary of Contents for T300MTX

Page 19: ...IF08CZ10 April 2019 xix This page intentionally left blank ...

Page 62: ...IF08CZ10 April 2019 40 CIRCUIT OPERATION cont d 6600V configuration ...

Page 78: ...IF08CZ10 April 2019 56 DRIVE INSTALLATION DRAWINGS Frame 0 drive lifting and assembly ...

Page 106: ...IF08CZ10 April 2019 84 DRIVE INSTALLATION DRAWINGS cont d Frame A2 drive lifting and assembly ...

Page 109: ...IF08CZ10 April 2019 87 DRIVE INSTALLATION DRAWINGS cont d Frame B2 drive lifting and assembly ...

Page 111: ...IF08CZ10 April 2019 89 DRIVE INSTALLATION DRAWINGS cont d Frame D2 drive lifting and assembly ...

Page 116: ...IF08CZ10 April 2019 94 DRIVE INSTALLATION DRAWINGS cont d Frame A4 drive lifting and assembly ...