MAINTENANCE MANUAL

106

STE 85357

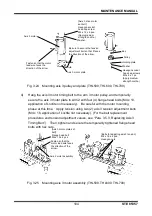

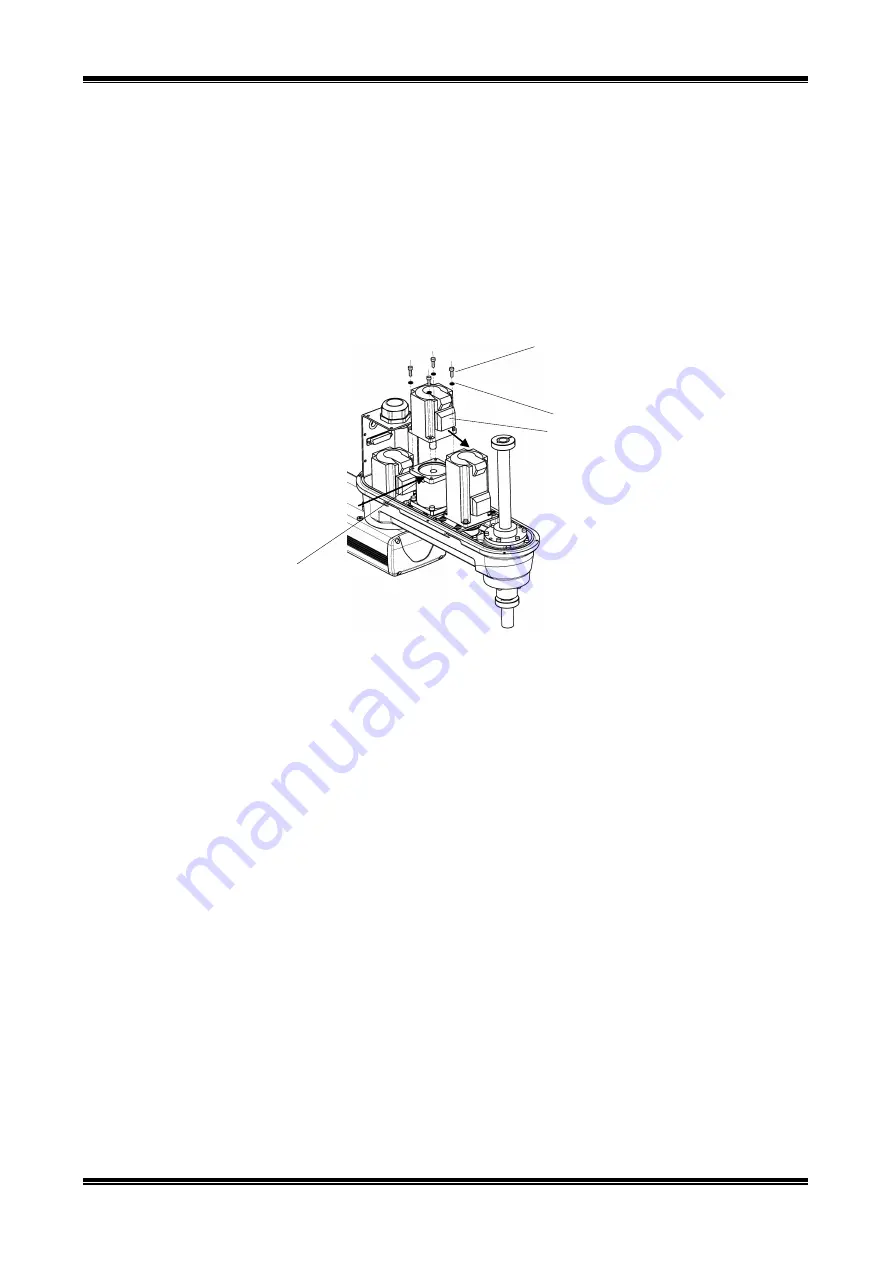

3.4.10 Mounting Axis 4 Motor

1)

Mount the new motor to the reduction gear with four (4) hexagon socket head

cap screws (M4 x 12) and washers. Be careful with the phase when mounting

the motor. (Recommended clamping torque: 2.3 N·m)

2)

Tighten the coupling of the axis 4 reduction gear by means of the attached bolt

(M4) to mount the cap. (Recommended clamping torque: 4.3 N·m)

Fig. 3.27 Mounting axis 4 motor (THL500, THL600, THL700)

3)

Connect the connectors of the axis 4 motor, i.e., J4AS and J4AP (power drive

cables), and J4BS and J4BP (encoder cables).

4)

Restore the cables to the original conditions and then mount the arm 2 cover.

5)

Set up the home positions of Axes 3 and 4 to complete motor replacement.

During the replacement of the axis 4 motor, it is necessary to set up the home

position of Axis 3.

6)

Carry out a test operation of Axes 3 and 4 and make sure that each part

operates properly.

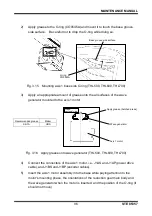

Cap

After clamping the coupling bolt,

insert in the arrow-marked

direction.

[Axis 4 drive motor set bolt]

Hexagon socket head cap screw

M4 x 12 x 4 pcs.

(Recommended clamping

torque: 2.3 N·m)

(Apply medium strength Loctite.)

Washer

Fasten so that the motor lead

wire faces the direction of the

arrow.