MAINTENANCE MANUAL

129

STE 85357

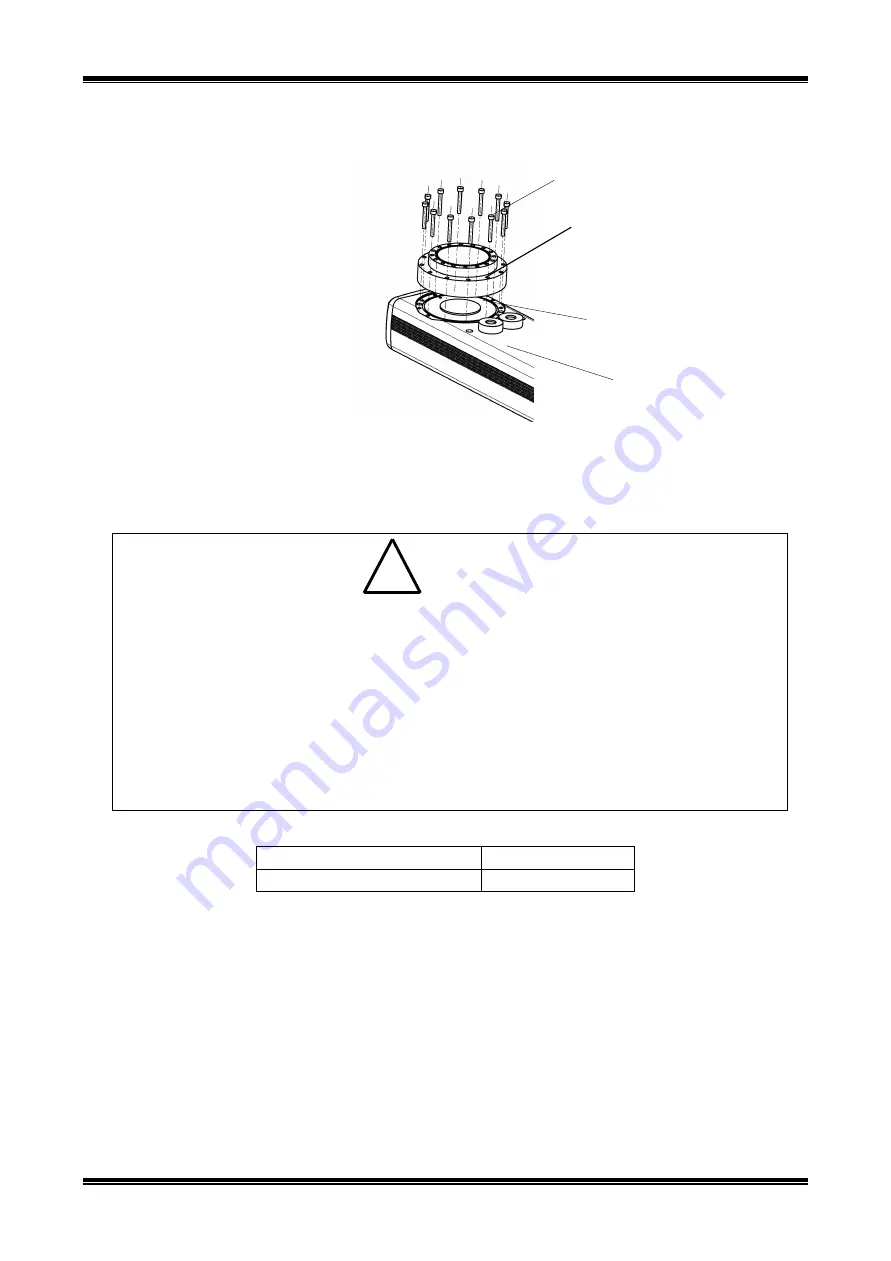

Fig. 3.46 Dismounting axis 1 reduction gear (THL500, THL600, THL700)

3.7.4

Mounting Axis 1 Reduction Gear

!

CAUTION

• Handle the reduction gear with extreme care. If it drops or an unusually large external

force is exerted on it, the reduction gear cannot function any further.

• Use the wave generator which is attached to the new reduction gear.

If the old center gear is used as it is, abnormal noise will be caused, the service life will

shorten or positioning accuracy will deteriorate due to incompatibility with the new reduction

gear.

• Also use the “O” ring attached to the new reduction gear. Be sure to set the “O” ring.

Unless the “O” ring is set, grease will leak from the axis 1 reduction gear set surface.

When mounting the reduction gear, take careful preca

utions not to break the “O” ring.

Recommended grease

Maker

SK-1A

HDS

1)

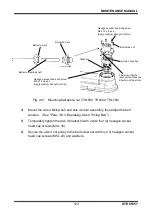

Mount a new wave generator provided as an accessory with a new reduction

gear. For the mounting procedure, see

“Para. 3.4.4, Mounting Axis 1 Motor.”)

2)

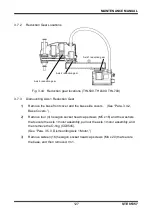

Cleanly wipe off dusts and stains on the axis 1 reduction gear of Arm 1. Apply

grease to an O-ring attached to the new reduction gear, and then mount it in the

O-ring groove of Arm 1.

3)

Secure the axis 1 reduction gear with twelve (12) hexagon socket head cap

screws (M4 x 30).

Arm 1

Remove the O-ring in advance.

Hexagon socket head cap screw

M4 x 30 x 12 pcs.

Axis 1 reduction gear