MAINTENANCE MANUAL

152

STE 85357

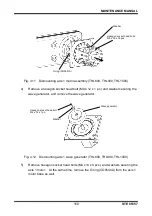

3)

Fix the wave generator using a hexagon socket head bolt (M12 x 4 x 1 pc.) and

washer. Apply grease to the O-ring (CO0551A) and set the O-ring into the

O-ring groove of the axis 1 motor mount.

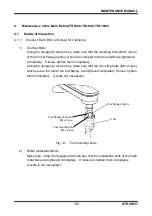

Fig. 4.15 Mounting axis 1 wave generator (THL800, THL900, THL1000)

4)

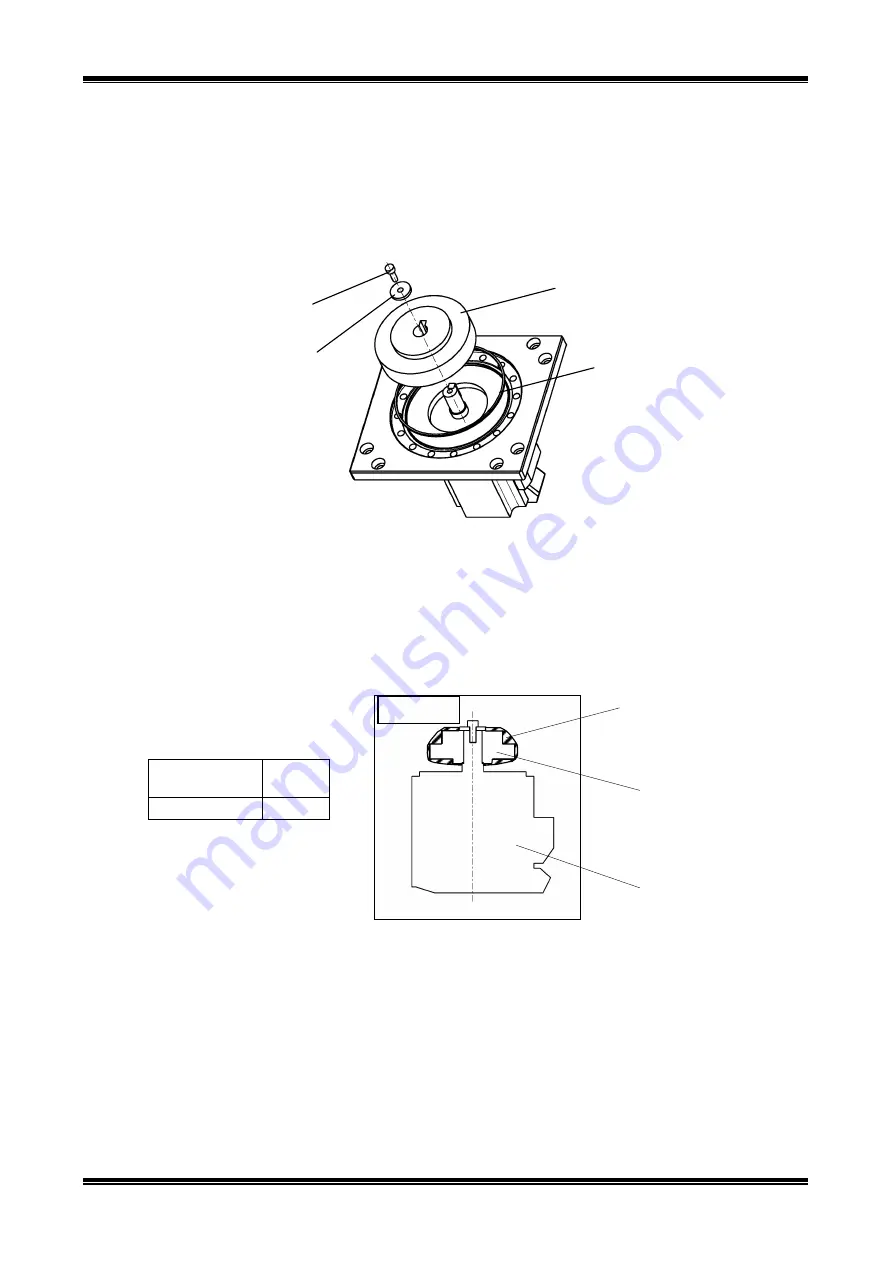

Apply an appropriate amount of grease onto the top and bottom surfaces of the

wave generator mounted to the axis 1 motor.

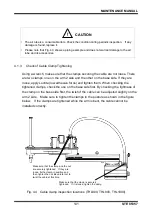

Fig. 4.16 Apply grease onto wave generator (THL800, THL900, THL1000)

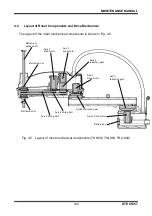

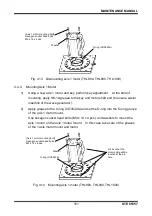

5)

Take care of the motor mounting phase, and directions of the reduction gear and

wave generator at the time of insertion of the motor (elliptical portions of the

reduction gear proper and wave generator should be adjusted). Make sure

that the O-ring is not misaligned. Then insert the axis 1 motor assembly into

the reduction gear proper.

Recommended

grease

Maker

SK-1A

HDS

Cross-

sectional view

Apply grease (hatched areas)

Wave generator

Axis 1 motor

Wave generator

Washer

Hexagon socket head bolt

M4 x 12 x 1 pc.

O-ring (CO0551A)