MAINTENANCE MANUAL

159

STE 85357

8)

Before turning on power subsequent to replacement of the axis 2 motor, move

the arm 2 by hand and make sure that there is no abnormal noise.

9)

Mount the axis 2 arm cover after the cables and others in the axis 2 arm have

been placed back to the original position.

10) Turn on the power and set up the home positions of axes 2 to complete axis 2

m

otor replacement (see “Section 6, Robot Home Point and Position Detector

Error”).

!

CAUTION

• Do not forget to mount the O-ring.

If the O-ring is not mounted, grease will leak from the motor mounted surface.

4.4.7

Dismounting Axis 3 Motor

!

CAUTION

• The axis 3 motor is provided with a brake. At replacement of the axis 3 motor, this brake

becomes inoperative. Before starting the work, therefore, move down the ball screw spline

to the lower limit. Otherwise, the shaft will drop due to the dead weight of the shaft or

workpiece, and your hand or finger may be caught.

1)

Remove the arm 2 cover.

(See “Para. 4.3.1, Arm 2 Cover.”)

2)

Cut the cable ties of the cables with nippers.

It is recommended to take photos of the cable installation positions and the

locations where cable ties are used so that these locations can be restored

when needed.

3)

Disconnect connectors J3AS and J3AP (power drive cables), connectors J3BS

and J3BP (encoder cables) and connectors J3DS and J3DP (brake cables) for

the axis 3, which are connected to the connector panel.

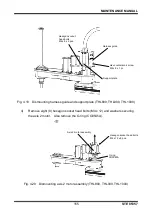

4)

Loosen the axis 3 tension adjustment bolt (M4 x 16 x 2 pcs. and hexagonal

nuts) and remove the flange head bolts (M4 x 10 x 4 pcs.) securing the axis 3