MAINTENANCE MANUAL

162

STE 85357

Ti

ming Belt.”) Then, tighten and secure the temporarily tightened flange head

bolts with hex nuts.

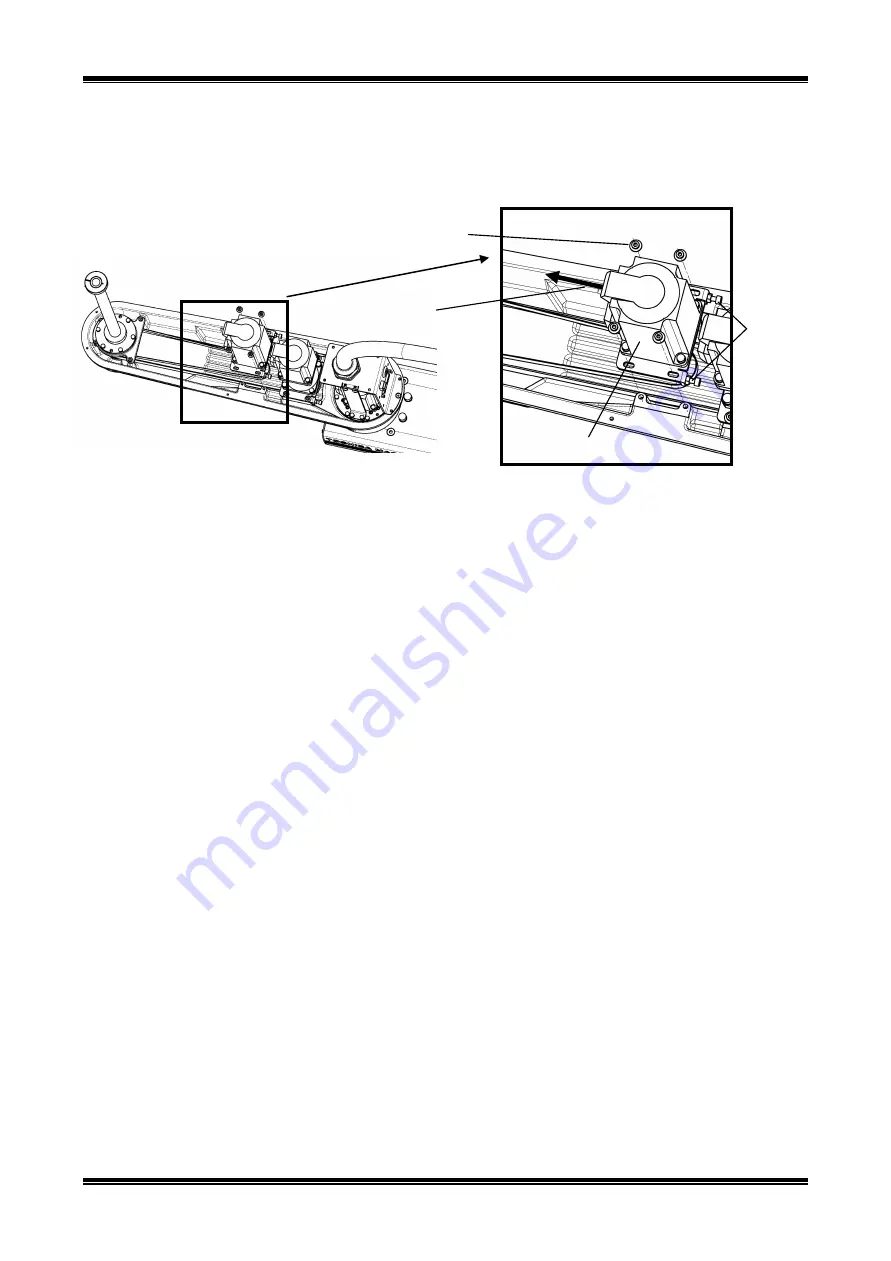

Fig. 4.30 Mounting axis 3 motor assembly (THL800, THL900, THL1000)

5)

Connect the connectors and set the cables back to the original state. (See the

pictures taken in Para. 4.4.7, Step 2.)

6)

Mount the arm 2 cover and perform home setting for Axes 3 and 4. Now, the

axis 3 motor replacement is complete.

7)

Carry out a test operation of Axes 3 and 4 and make sure that each part

operates properly.

4.4.9

Dismounting Axis 4 Motor

1)

Remove t

he arm 2 cover. (See “Para. 4.3.1, Arm 2 Cover.”)

2)

Cut the cable ties of the cables with nippers.

It is recommended to take photos of the cable installation positions and the

locations where cable ties are used so that these locations can be restored

when needed.

3)

Disconnect connectors J4AS and J4AP (power drive cables) and connectors

J4BS and J4BP (encoder cables) of the axis 4 motor.

4)

Remove the cap attached to the lateral side of the axis 4 reduction gear and

loosen the coupling bolt (M4) securing the axis 4 motor shaft and input shaft of

the axis 4 reduction gear.

If the hexagonal hole of the bolt is out of phase, adjust the phase by turning the

ball screw spline shaft by hand.

[Axis 3 motor plate mounting bolt]

Flange head bolt

M4 x 10 x 4 pcs.

Fasten so that the motor

lead wire faces the

direction of the arrow.

Bolts for adjusting

axis 3 tension

M4 x 16 x 2 pcs.

Hexagon nuts

Axis 3 motor assembly