MAINTENANCE MANUAL

17

STE 85357

1.5

Clamping Hexagon Socket Head Cap Screws and Set screws

This robot uses hexagon socket head cap screws at places requiring mechanical

strength. At the time of factory-assembly, Loctite is applied and each screw is

tightened with the following clamping torque.

When these screws and set screws are tightened again according to the inspection

and maintenance as stipulated in this manual, use a torque wrench or torque driver,

and Loctite (medium strength) to assure the appropriate clamping torque.

The places which do not fall under the table below are detailed in the paragraph of

the replacement procedures.

Table 1.4 Clamping Torque

Hexagon socket

head cap screw

M3

M4

M5

M6

M8

M10

M12

Set screws

M3

M4

M5

M6

M8

M10

M12

M16

M20

Clamping

torque

1.5N

・

m

1.8N

・

m

2.0 N

・

m

4.7 N

・

m

9.0 N

・

m

15 N

・

m

37 N

・

m

75 N

・

m

128 N

・

m

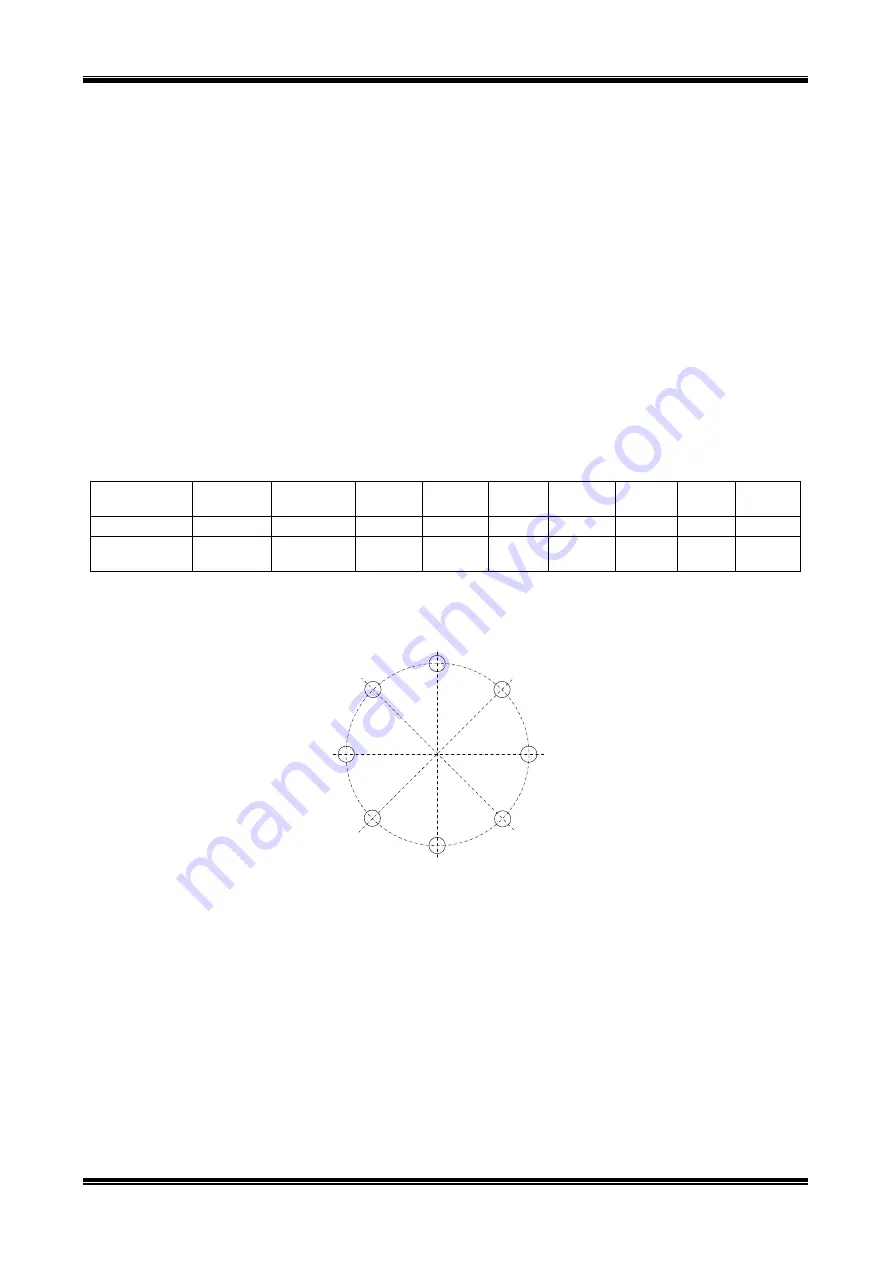

For the screws arranged on a circle for mounting the reduction gear, etc., tighten

them in the diagonal order, as shown below.

Fig.1.2 Tool set bolts

DO NOT tighten one (1) screw at a time. Tighten each screw in multiple steps,

using a hexagonal wrench key, and secure with appropriate clamping torque by

means of a torque wrench.

1

8

7

6

5

4

3

2