MAINTENANCE MANUAL

66

STE 85357

8)

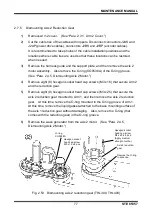

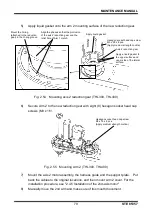

Remove the hexagon socket head cap screw (M4 x 12 x 6 pcs.) securing the

ball spline nut, and pull out the ball spline nut downward.

If it is hard to remove the ball spline nut, lightly tap the pulley with a plastic

hammer or similar tool that does not make scratches and then remove the ball

spline nut. If the pulley is pounded with a hammer or forcibly pulled out, Arm 2

may be deformed and, as a result, a new ball screw cannot be mounted

accurately.

9)

Disconnect the axis 4 nut pulley secured to the ball spline nut with the hexagon

socket head cap screw (M4 x 10 x 6 pcs.).

Fig. 2.43 Dismounting ball screw spline nut (THL300, THL400)

10)

Insert the disconnected ball spline nut into the ball screw spline shaft.

A marking for phase adjustment is stamped on both the ball screw spline shaft

and the ball spline nut. Align the two markings when inserting the ball spline

nut. To prevent the nut from slipping off, wind cable ties around near the top

and bottom of the shaft.

Hexagon socket

head cap screws

M4 x 12 x 6 pcs.

Ball spline nut

Axis 4 nut pulley

Hexagon socket

head cap screws

M4 x 10 x 6 pcs.