MAINTENANCE MANUAL

70

STE 85357

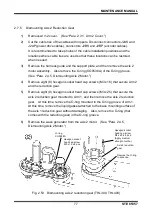

Fig. 2.46 Mounting ball screw spline nut (THL300, THL400)

8) Mount the axis 4 motor assembly and adjust the belt tension. (See "Para. 2.6.4,

Replacing Axis 4 Timing Belt.")

9)

Mount the axis 3 motor assembly and the axis 3 timing belt, and then adjust the

belt tension. (See "Para. 2.6.3, Replacing Axis 3 Timing Belt.")

10)

Mount the harness guide and the support plate with the cross recessed flat head

screw (M3 x 6 x 1 pc.) and the hexagon socket head cap screws (M3 x 6 x 2

pcs.), and restore the connectors and the cables to the original conditions.

(Refer to the photos taken in advance for reference.)

11)

Perform home setting for Axes 3 and 4.

When performing home setting for the axis 4, align the stopper split line with the

home point match-mark on the ball spline nut.

After home setting, remove the mating mark from the old ball spline nut, and

attach it to the new one. For the location of home point match-mark, see Para.

7.4.4, Location of Robot Home Point Match-Marks (THL300, THL400).

12)

Carry out a test operation of Axes 3 and 4 and make sure that each part

operates properly.

13)

Mount the arm 2 cover. Now replacement of the ball screw spline unit

completes.

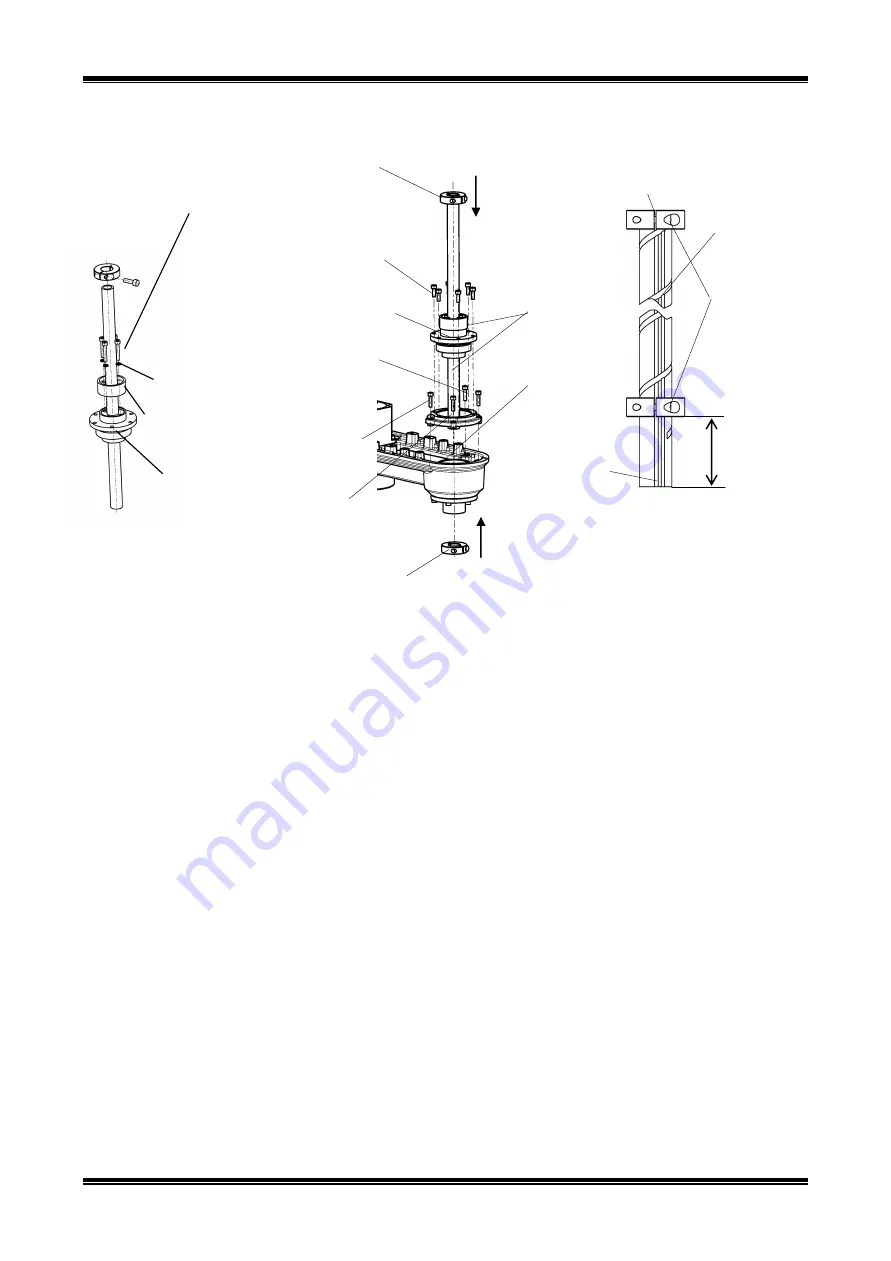

Washer

Pulley for the

axis 3 nut

27

Stopper

Stopper split line

Ball screw

groove

The bolt head

must be on the

right side.

Spline groove

Align each stopper split line with the

spline groove on the left of the

bottommost ball screw groove.

Stopper

Ball screw nut

Ball screw spline shaft

Ball screw nut

Axis 4 timing belt

Axis 3 bracket (casting)

Hexagon socket head cap screw

M4 x 12 x 6 pcs.

(Apply medium strength Loctite.)

Hexagon socket head cap screw

M4 x 25 x 4 pcs.

(Apply medium strength Loctite.)

Hexagon socket

head cap screw

M4 x 16 x 4 pcs.

(Apply medium

strength Loctite.)

Never remove.