TOSHIBA

11.0

Expanded Information

11.1

PID Set Point Control

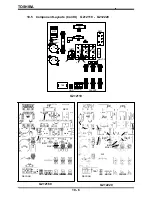

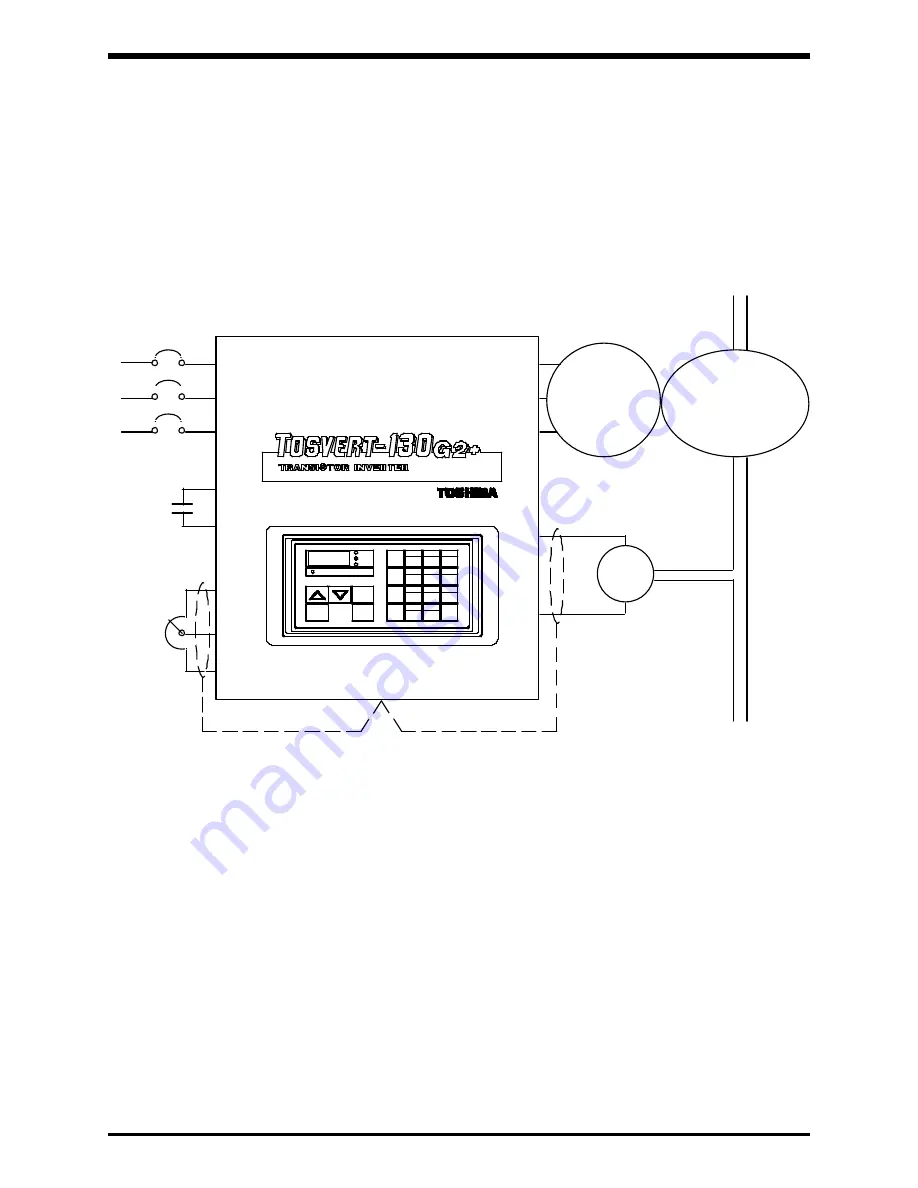

All G2+ inverters come standard with set point control. The following information shows

how to install and adjust the inverter using set point control. The feedback signal should

be either 0-5 volts or a 4-20mA current. It is connected to terminals IV and CC. The

setpoint may be adjusted by either a potentiometer or the touch pad. This diagram shows

how a potentiometer should be connected to terminals PP, RR, and CC to control the

setpoint. Each of these connections are made to the TB terminal strip located on the

main control printed circuit board PCB1.

The connection diagram below shows the necessary wiring.

11 - 1

L1

L2

L3

CC

RR

PP

CC

F

T3

T2

T1

MOTOR

PUMP

X

IV

CC

GND

+

_

PRESSURE

TRANSDUCER

SET

POINT

START

AC

INPUT

Use the following procedures to adjust the setpoint control parameters:

INITIAL SETUP

1)

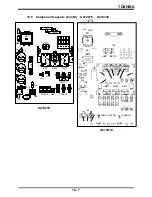

With power removed, place the jumper connections JP1 and JP2 (located on the

main control printed circuit board PCB1) in the correct positions for the type of

feedback signal used; then reapply power.

2)

Set acceleration and deceleration times to 5 seconds (1st function # 2).

3)

Adjust the bias and gain for the systems feedback signal. For example, typically the

motor slows down when the feedback signal goes above the setpoint. This action

can be reversed by exchanging the data between F-P1 and F-P2 (1st function # 5).

4)

Turn on the set point (PID) control (2nd function # 5).

5)

Set proportional gain to 1000 (2nd function # 5).

6)

Set integral gain to 500 (2nd function # 5).

7)

Set anti-hunting (differential) gain to 0 (2nd function # 5).

8)

Set lag-time constant to 255 (2nd function # 5).

9)

Run system.

Summary of Contents for TOSVERT-130G2+

Page 112: ...TOSHIBA 10 6 Schematics 10 17 ...