TOSHIBA

Inverter's software version

7.5.2

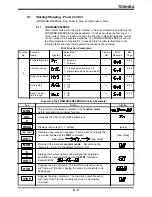

Tripped Status Monitoring (Cont'd)

In the event of a trip, the following statuses could be observed provided

monitoring is done prior to resetting the inverter. These statuses reflect the

conditions which existed at the time the inverter tripped.

Additional Tripped Status Monitoring

7 - 8

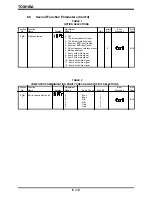

Key

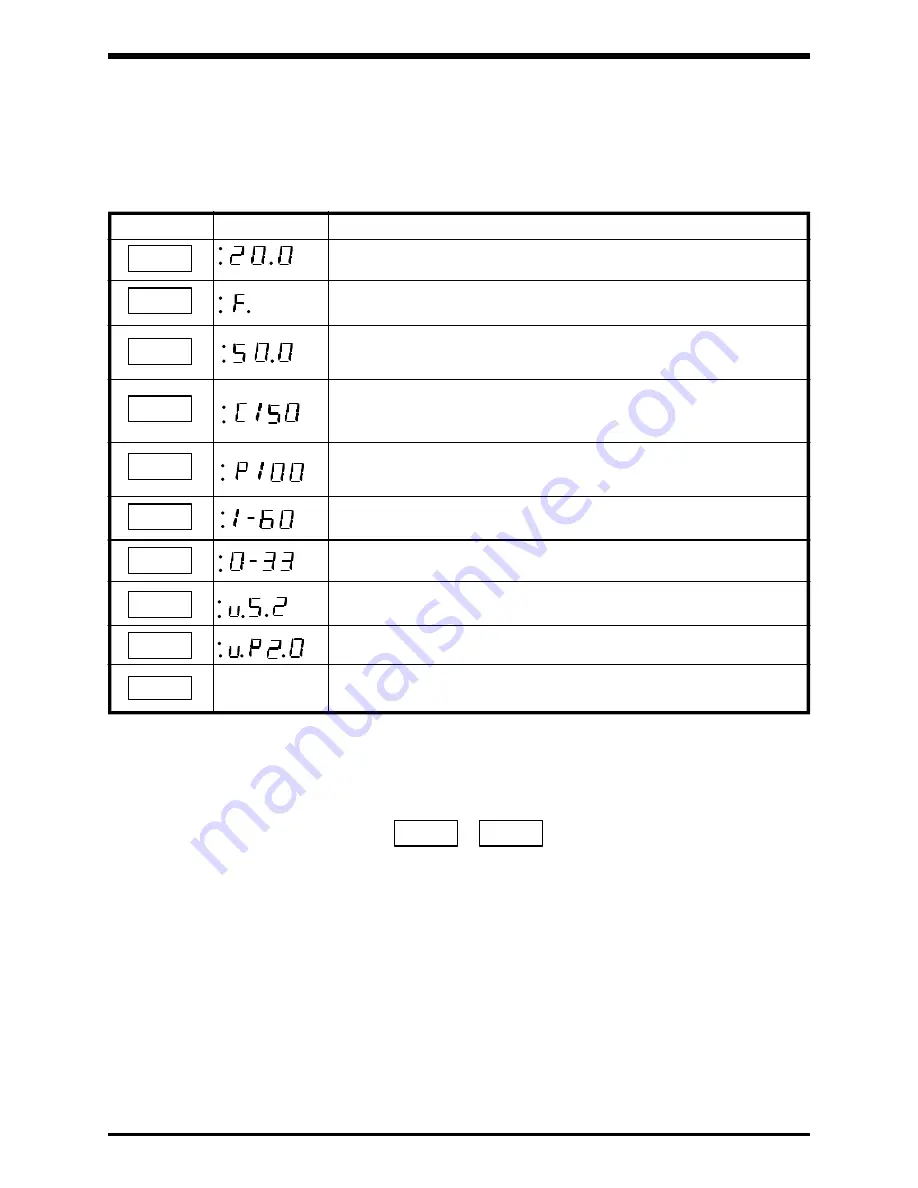

Display

Status

Output terminal status code at trip. See section 7.5.4

Keypad's software version

Original fault

Returns to the original display.

display

Operating frequency at trip was 20.0Hz.

The set value of operating frequency at trip was 50.0Hz.

The output current at trip was 150% (150% of the inverter's rated

output current).

The output voltage at trip was 100% (100% of the inverter's rated

voltage).

Input terminal status code at trip. See section 7.5.3

Rotating direction at trip was in the forward direction.

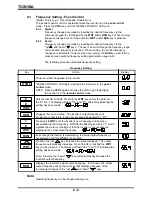

NEXT

NEXT

NEXT

NEXT

NEXT

NEXT

NEXT

NEXT

NEXT

NEXT

Note:

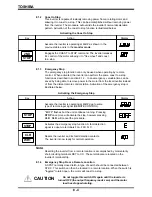

Resetting the drive after a trip can be accomplished either of two ways:

1)

Reset from panel - press

2)

Reset from remote - momentary contact closure between terminals RST and CC.

CLR

WRT

Summary of Contents for TOSVERT-130G2+

Page 112: ...TOSHIBA 10 6 Schematics 10 17 ...