TOSHIBA

8.7

Operating Functions - Descriptions and Examples (Cont'd)

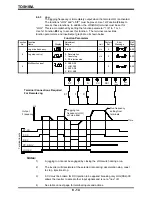

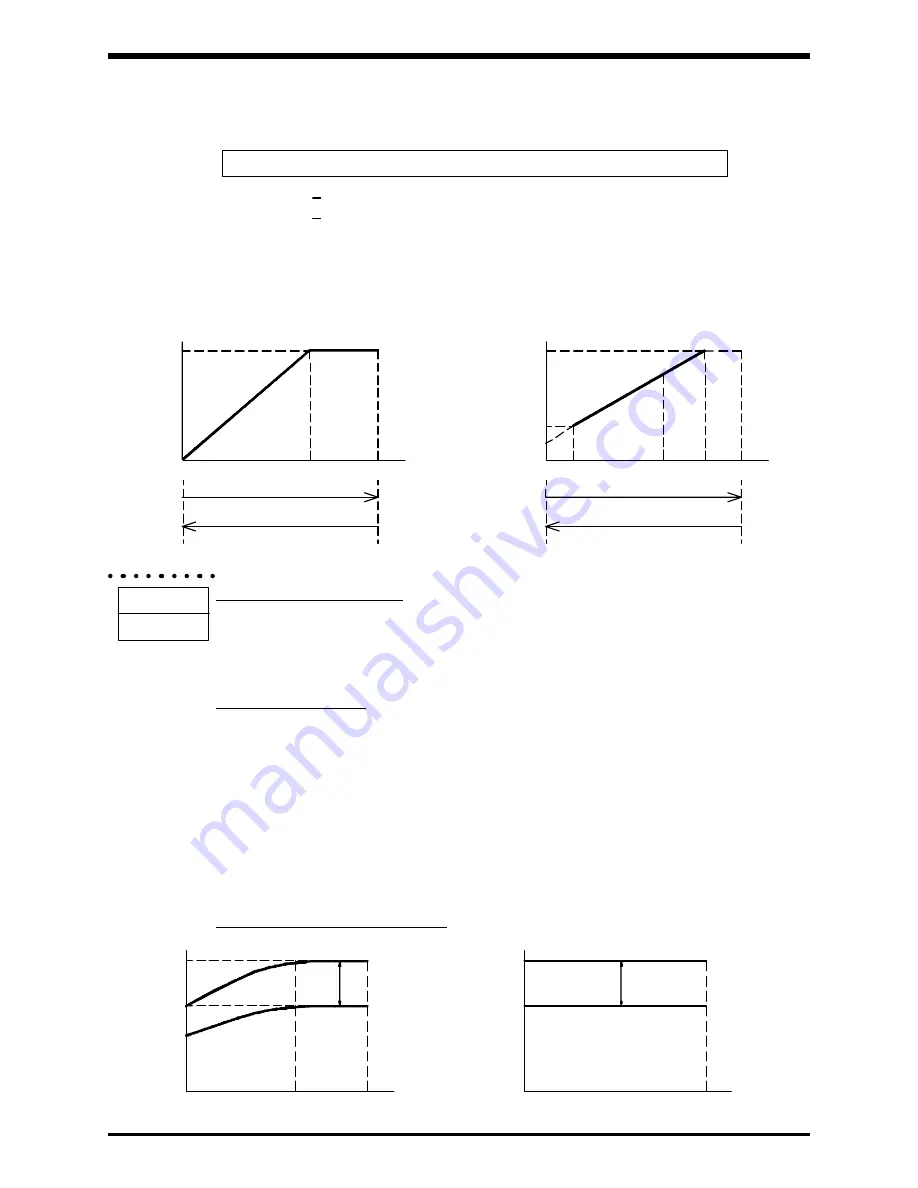

Because ACC/DEC times are based upon the change in Hz/SEC the following

formula must be used.

8 - 22

FH/Frequency range X (ACC/DEC time of frequency range) = ACC/DEC

ACC1 = 80Hz : (60-20Hz) X 30 sec. = 60 sec.

ACC1=60

DEC1 = 80Hz : (60-20Hz) X 10 sec. = 20 sec.

DEC1=20

80 UL, FH

60

ACC

DEC

10 sec.

ACC

DEC

20 sec.

20

LL

10

50

60

UL

100

FH

100

LL

10 sec.

60 sec.

Hz

Hz

% Voltage

% Voltage

Note:

Specifications required only one ACC/DEC rate, therefore ACC2/DEC2/Pt2

settings were not needed:

SEL2=0

Setting ACC2/DEC2/Pt2 would be suggested if a different pattern was required.

Switching between the two patterns would then simply require switching between

SEL2=0 and SEL2=1.

FACTORY SETTINGS

EXAMPLE SETTINGS

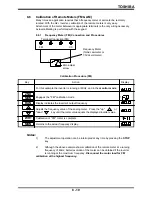

OL

OVERLOAD PROTECTION - Sets the thermal overload detection level to match the

ratings and characteristics of the motor being used (10% to 100% of rated output

current). The inverter will run continuously at 110% of the

overload protection

(i.e.

Setting: inverter rated current = 50amps, overload level set at 60% leads to set rated

current = 50 X 60% = 30amps and continuous set rated current = 30 X 110% = 33amps).

STALL PROTECTION - Sets the activation level of the stall protection function (90% to

150% of rated output current). When the stall level is reached the inverter will begin

stalling by lowering the frequency and voltage to prevent

overcurrent

tripping. Once a

soft stall has occurred the output current will be clocked. If output current is not reduced

within a specified time a fault will occur. (See section 3.0 for ratings and section 7.5.2 for

fault codes.)

Note:

Instantaneous trip current limits are factory set and are dependent upon inverter

size as well as the motor ripple current. The inverter's soft stall function is

particularly effective in situations where load current decreases as revolution

speed decreases (i.e. wind and hydraulic power machinery).

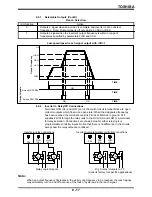

OVERLOAD DETECTION CURVE - Selects an overload detection curve for a standard

motor or a variable frequency motor, with and without soft stall.

4

FMAX

45Hz

FMAX

0

0

100%

60%

100%

60%

FOR STANDARD MOTORS

FOR VF MOTORS

Frequency

Frequency

Overload

detection level

Overload

detection level

Summary of Contents for TOSVERT-130G2+

Page 112: ...TOSHIBA 10 6 Schematics 10 17 ...