E6581090

N-1

14

14. Inspection and maintenance

Danger

Mandatory

•

The equipment must be inspected every day.

If the equipment is not inspected and maintained, errors and malfunctions may not be

discovered which could lead to accidents.

•

Before inspection, perform the following steps.

①

Shut off all input power to the inverter.

②

Wait for at least 15 minutes and check that the charge lamp is no longer lit.

③

Use a tester that can measure DC voltages (800V DC or more), and check that the

voltage to the DC main circuits (across PA-PC) does not exceed 45V.

Performing an inspection without carrying out these steps first could lead to electric shock.

Be sure to inspect the inverter regularly and periodically to prevent it from breaking down because

of the environment of use, such as temperature, humidity, dust and vibration, or deterioration of its

components with aging.

14.1

Regular inspection

Since electronic parts are susceptible to heat, install the inverter in a cool, well-ventilated and dust-

free place. This is essential for increasing the service life.

The purpose of regular inspections is to maintain the correct environment of use and to find any

sign of failure or malfunction by comparing current operation data with past operation records.

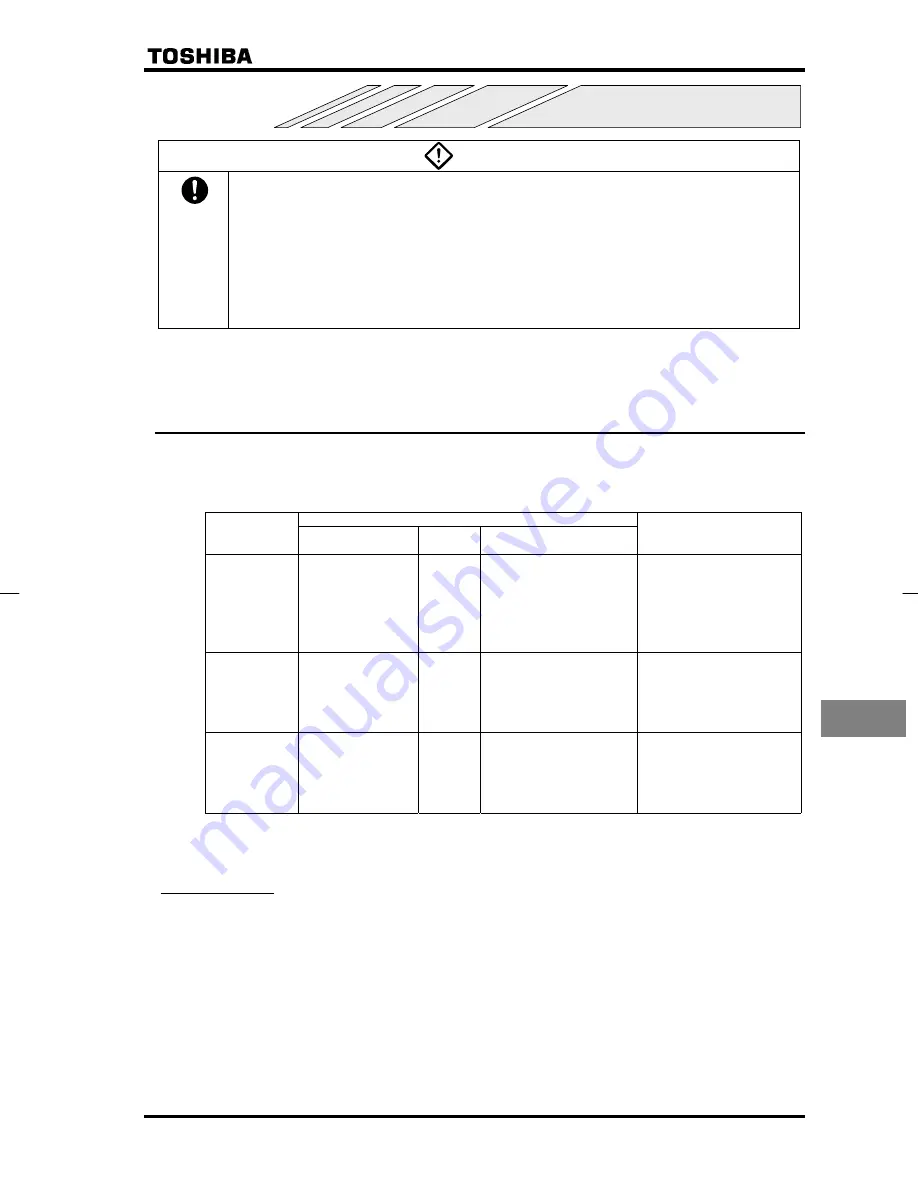

Inspection procedure

Subject of

inspection

Inspection item

Inspection

cycle

Inspection method

Criteria for judgment

1) Dust, temperature

and gas

Occasionally 1) Visual check, check by

means of a thermometer,

smell check

1) Improve the environment if

it is found to be

unfavorable.

2) Drops of water or

other liquid

Occasionally 2) Visual check

2) Check for any trace of

water condensation.

1. Indoor

environment

3) Room

temperature

Occasionally 3) Check by means of a

thermometer

3) Max. temperature: 40

°

C

(50

°

C inside the cabinet)

2. Units and

components

1) Vibration and

noise

Occasionally Tactile check of the cabinet

If something unusual is found,

open the door and check the

transformer, reactors,

contactors, relays, cooling fan,

etc., inside. If necessary, stop

the operation.

1) Load current

Occasionally Moving-iron type AC

ammeter

2) Voltage (*)

Occasionally Rectifier type AC voltmeter

3. Operation

data

(output side)

3) Temperature

Occasionally Thermometer

To be within the rated

current, voltage and

temperature.

No significant difference from

data collected in a normal

state.

*) The voltage measured may slightly vary from voltmeter to voltmeter. When measuring the

voltage, always take readings from the same circuit tester or voltmeter.

■

Check points

1. Something unusual in the installation environment

2. Something unusual in the cooling system

3. Unusual vibration or noise

4. Overheating or discoloration

5. Unusual odor

6. Unusual motor vibration, noise or overheating