E6581090

F-17

6

6.11

Performing PI control

H

: PI control

H

: Proportional (P) gain

H

: Integral (I) gain

•

Function

These parameters are used to perform various kinds of process control, such as keeping the air quantity, flow

rate or pressure constant by inputting feedback signals (4~20mA, 0~10V) from a detector.

[Parameter setting]

Title

Function

Adjustment range

Default setting

H

PI control

0: Disabled, 1: Enabled

0

H

Proportional (P) gain

0.01

~

100.0

0.30

H

Integral (I) gain

0.01

~

100.0

0.20

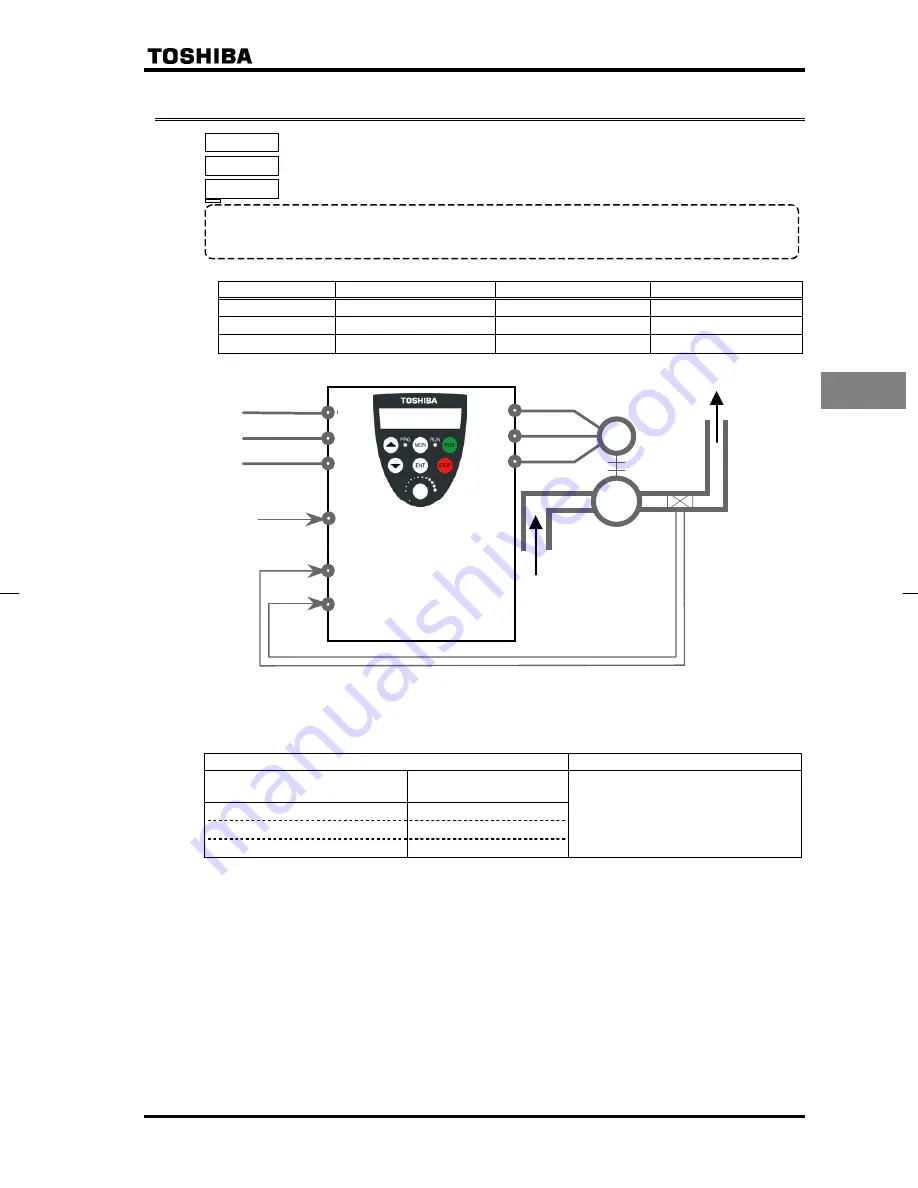

1) External connection

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

VI/S3

M

P

Pressure

gauge

②

Panel input setting

③

Preset speed

setting

Feedback signal: 4~20mA, 0~10V

CC

S1

S2

・

・

①

Potentiometer setting

2) Types of PI control interfaces

The following combinations of process quantity data (frequency setting) and feedback data can be

entered for PI control.

Process quantity input data (frequency setting)

Feedback input data

Setting mode

Frequency setting mode

HOQF

①

Internal potentiometer setting

②

Panel input setting

③

Preset speed setting

or

External analog input

H

: 0 (voltage input)

①

VI/S3 (DC: 0~10V)

H

:1 (current input)

②

VI/S3 (DC: 4~20mA)

Note: When the PI control function is enabled (

H

: 1), the VI/S3 terminal is used exclusively

as a feedback signal input terminal.

Note: Do not set Frequency setting mode (

HOQF

) parameter to 0 if VI/S3 terminal is not used

as contact input.

If all terminals for preset speed are off, a speed command other than the preset speed

3) Setting the PI control parameter

Set the extended parameter

H

(PI control) to

(enabled).

(1) It is recommended to set the parameters

CEE

(acceleration time) and

FGE

(deceleration

time) to as small values as possible.

(2) If there is a need to limit the output frequency, set it with the parameters

WN

(upper limit

frequency) and

NN

(lower limit frequency). When process quantities are set from the operation

panel, their adjustment ranges are limited by the settings of

WN

(upper limit frequency) and

NN

(lower limit frequency).