E6581595

E-21

5

5) Use a motor that has 2-8 P.

6) Always operate the motor in single operation (one inverter to one motor). Sensorless vector control cannot

be used when one inverter is operated with more than one motor.

When using a combination of several motors, set the V/F constant (

=

).

7) The maximum length of wires between the inverter and motor is 30 meters. If the wires are longer than 30

meters, set standard auto-tuning with the wires connected to improve low-speed torque during sensorless

vector control.

However the effects of voltage drop cause motor-generated torque in the vicinity of rated frequency to be

somewhat lower.

8) When a reactor is connected between the inverter and a motor, the motor's generated torque may fall.

Setting auto-tuning may also cause a trip (

) rendering sensorless vector control unusable.

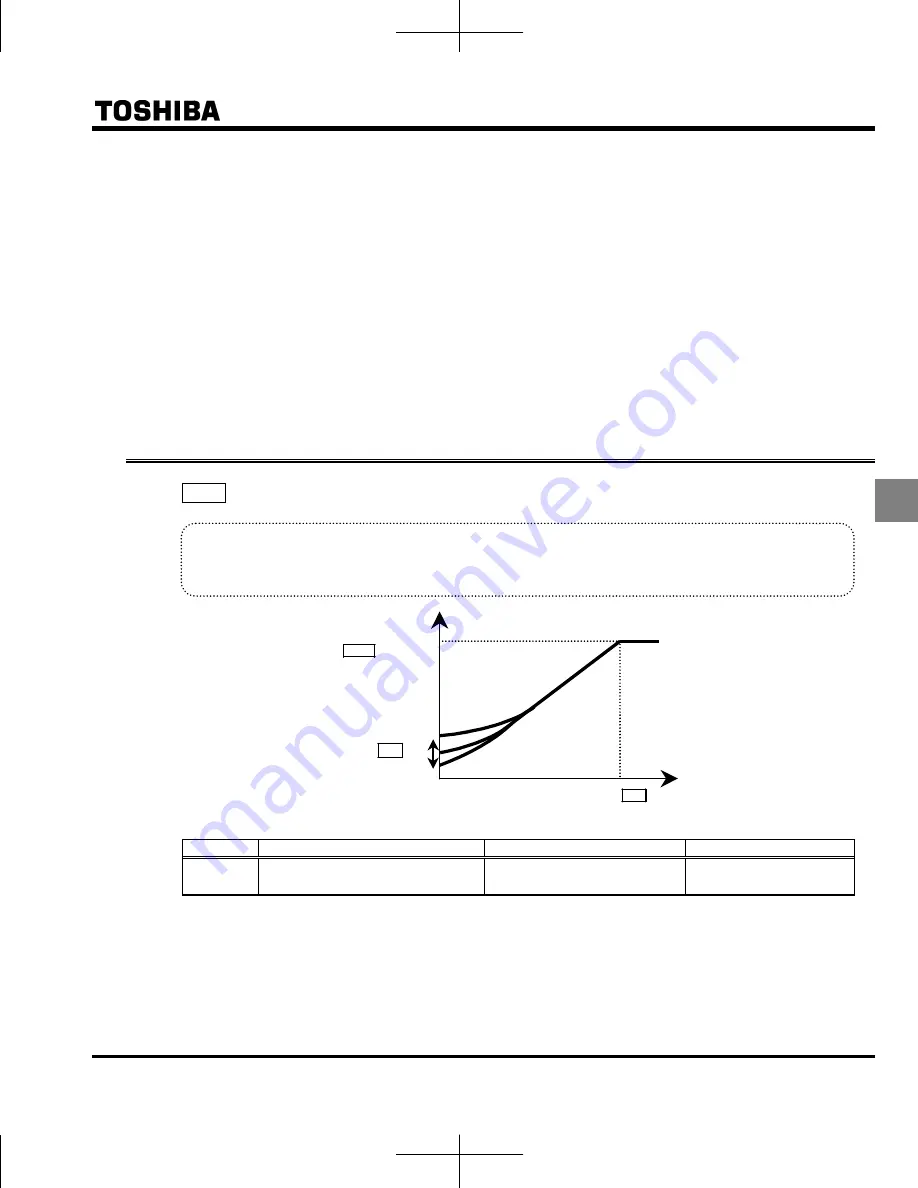

5.12 Manual torque boost - increasing torque boost at low

speeds

: Torque boost 1

Function

If torque is inadequate at low speeds, increase torque by raising the torque boost rate with this

parameter.

O

ut

put

v

ol

ta

ge

[V

]/(

%

)

Base frequency voltage

Output frequency (Hz)

Base frequency

[Parameter setting]

Title Function

Adjustment range

Default setting

Torque boost value 1

0.0 - 30.0 (%)

According to model

(Refer to section 11.4)

Valid when

is set to

0

(V/F constant) or

1

(square reduction)

Note 1: The optimum value is programmed for each inverter capacity. Be careful not to increase the torque boost

rate too much because it could cause an overcurrent trip at startup.