E6581595

A-9

1

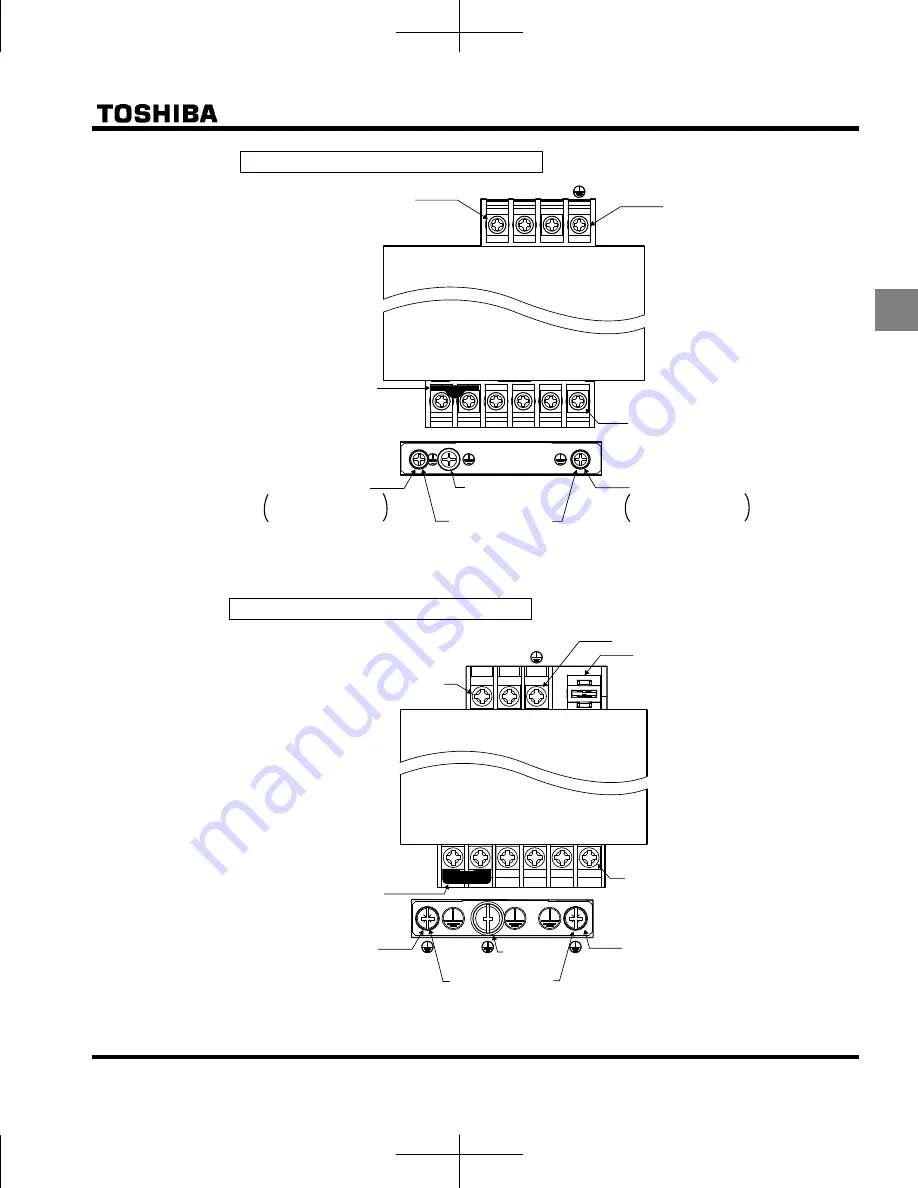

VFNC3-2015

2037P

R/L1 S/L2 T/L3

P0

PA/+ PC/- U/T1 V/T2 W/T3

Grounding terminal

M4 screw

Short-circuit cover

Grounding terminal

(M5 screw)

EMC plate

for installation (Note 1)

M4 screw

Grounding terminal

M4 screw: 2015, 2202

M5 screw: 2037

Grounding terminal

M4 screw: 2015, 2202

M5 screw: 2037

* Bend the clips on the wiring port of the terminal cover to connect the PO, PA/+, and PC/- terminals.

VFNC3S-1001

~

1004P

,

2001

~

2007PL

R/L1 S/L2/N

P0

PA/+ PC/- U/T1 V/T2 W/T3

M3.5 screw

Grounding capacitor switch

(2001 to 2007 PL only)

Grounding terminal

(M4 screw)

M3.5 screw

Grounding terminal

Short-circuit cover

EMC plate

for installation (Note 1)

Grounding

terminal

(M5 screw)

Grounding terminal

* Bend the clips on the wiring port of the terminal cover to connect the PO, PA/+, and PC/- terminals.

Shorting-bar

Shorting-bar

(M4 screw)