E6581595

M-2

13

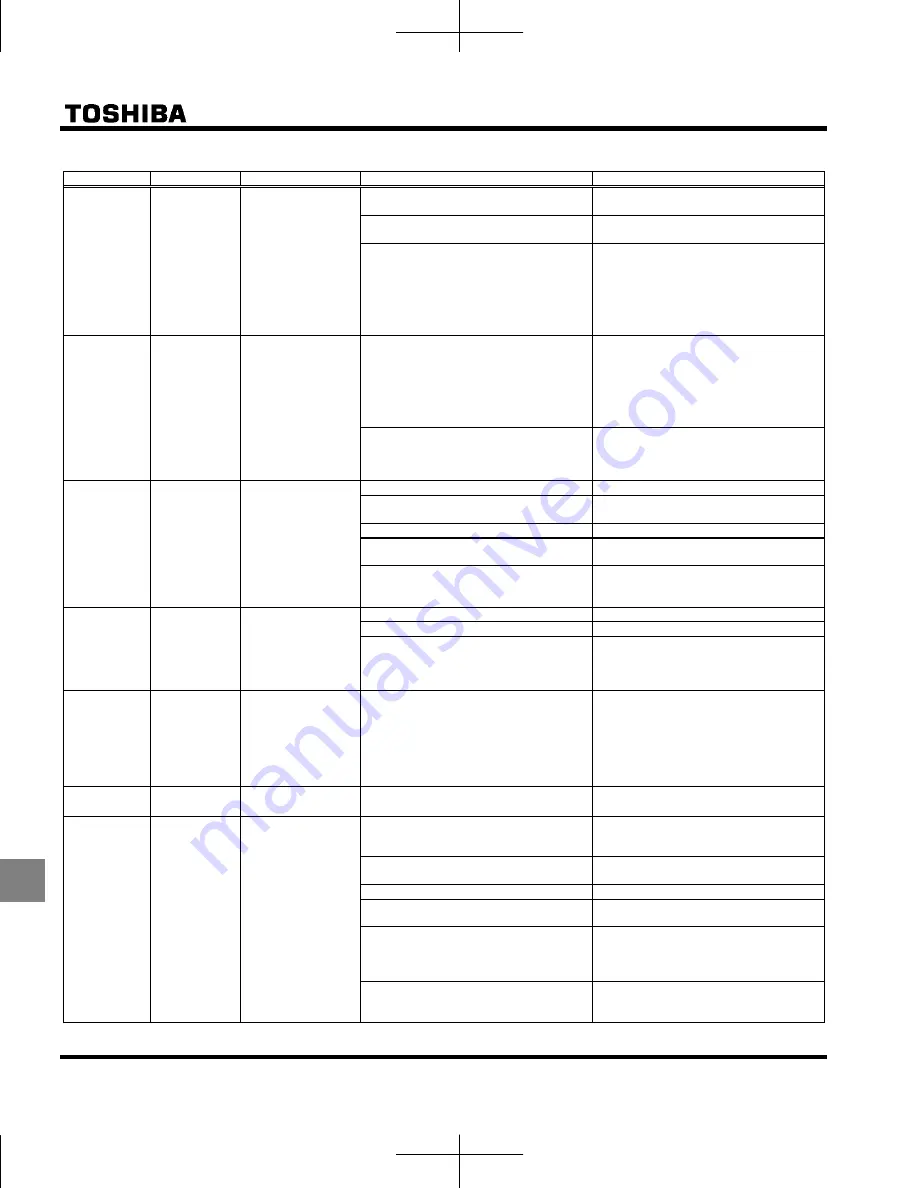

[Trip information]

Error code

Failure code

Name

Description

Remedies

000B Overvoltage

during

deceleration

The deceleration time

is too short.

(Regenerative energy is too large.)

Increase the deceleration time

.

Overvoltage

limit

operation

is set

to

1

. (Disabled).

Set overvoltage limit operation

to

0

,

2

,

3

.

The input voltage fluctuates abnormally.

(1) The power supply has a capacity of

200kVA or more.

(2) A power factor improvement capacitor is

opened and closed.

(3) A system using a thyristor is connected

to the same power distribution line.

Insert a suitable input reactor.

000C Overvoltage

during

constant-speed

operation

The input voltage fluctuates abnormally.

(1) The power supply has a capacity of

200kVA or more.

(2) A power factor improvement capacitor is

opened or closed.

(3) A system using a thyristor is connected

to the same power distribution line.

Insert a suitable input reactor.

The motor is in a regenerative state

because the load causes the motor to run

at a frequency higher than the inverter

output frequency.

Install an optional brake module.

000D Inverter

overload

The acceleration time ACC is too short.

Increase the acceleration time

.

The DC braking amount is too large.

Reduce the DC braking amount

and the DC braking time

.

The V/F setting is improper.

Check the V/F parameter setting.

A restart signal is input to the rotating

motor after a momentary stop, etc.

Use

(auto-restart) and

(ride-through control).

The load is too large.

Use an inverter with a larger rating.

Reduce

f300

(PWM carrier frequency)

to 4kHz or less.

000E Motor

overload

The V/F setting is improper.

Check the V/F parameter setting.

The motor is locked up.

Check the load (operated machine).

Low-speed operation is performed

continuously.

An excessive load is applied to the motor

during operation.

Adjust

to the overload that the

motor can withstand during operation in a

low speed range.

003E Main

module

overload

The carrier frequency is high and load

current has increased at low speeds

(mainly at 15Hz or less).

Raise the operation frequency.

Reduce the load.

Reduce

f300

: PWM carrier frequency.

When an operating motor is started up at

0Hz, use the auto-restart function.

Set

f316

=

1

(Carrier frequency with

automatic reduction).

*

0020 Over-torque

trip

Over-torque reaches to a detection level

during operation.

Enable

(over-torque trip selection).

Check system error.

0010 Overheat

The cooling fan is life or fault

.

The cooling fan requires replacement if it

does not rotate during operation.

Contact your Toshiba distributor.

The ambient temperature is high or low

outside a specified ambient temperature.

Operate at a specified ambient

temperature.

The vent of the cooling fan is blocked up.

Secure sufficient space around the inverter.

A heat generating device is installed close

to the inverter.

Do not place any heat generating device

near the inverter.

The load is large.

Reduce the load.

Reduce

f300

: PWM carrier frequency.

Set

f316

=

1

(Carrier frequency with

automatic reduction).

The temperature sensor is fault.

(Even if it resets after much time, When

always generating)

Contact your Toshiba distributor.

* You can select a trip ON/OFF by parameters.